Polyurethane and process for preparing nano composite materials thereof

A technology of nanocomposite materials and polyurethane, which is applied in the field of preparation of polyurethane and its nanocomposite materials, can solve the problems of complex process, high manufacturing cost and long reaction time, and achieve the effect of simple operation, shortened reaction time and good gloss performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

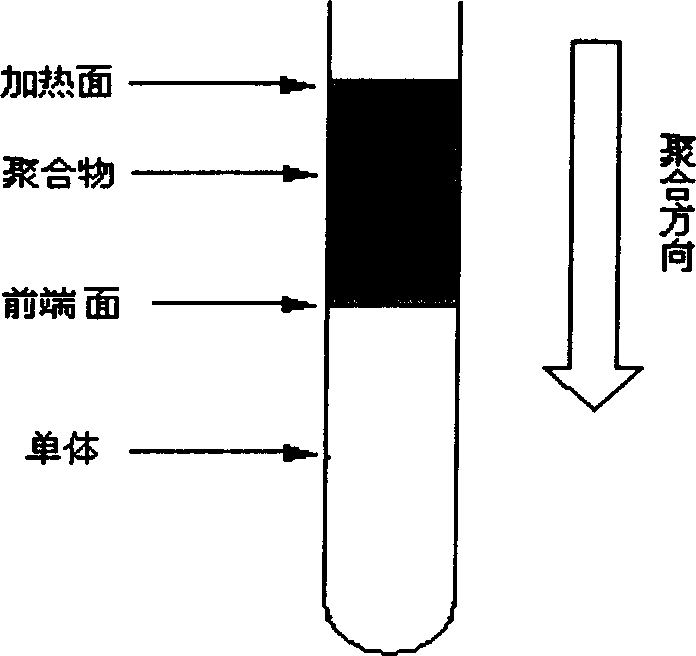

[0030] 2.3g of TDI, 10g of propylene glycol polyoxypropylene ether, 0.45g of 1,4-butanediol and 1.5g of toluene are stirred in the presence of 0.07g of stannous octoate, then quickly poured into the reactor, as figure 1 As shown, use a heater such as an electric rod to heat the above system for a short time at the upper end of the liquid in the reactor for 50 seconds at a heating temperature of 110°C, then stop heating, and complete the monomer polymerization by means of the heat self-catalysis of the exothermic reaction, that is, the front-end polymerization reaction , the aggregation direction is as figure 1 As shown in the direction of the middle arrow, a polyurethane material was prepared. The glass transition temperatures determined for this material are listed in Table 1.

Embodiment 2

[0032] 0.25g nano-SiO 2 The powder is pre-dispersed with 2.3g of TDI, 10g of propylene glycol polyoxypropylene ether, 0.45g of 1,4-butanediol and 1.5g of toluene in the presence of 0.07g of stannous octoate, stir well and quickly pour into the reactor In one end of the reactor, the above system is heated for 50s for a short time, the heating temperature is 110°C, then the heating is stopped, and the monomer polymerization is completed by means of the thermal self-catalysis of the exothermic reaction, and the polyurethane and its components with good stability are prepared. Polyurethane nanocomposites. The glass transition temperatures determined for this material are listed in Table 1.

Embodiment 3

[0034] 0.1g nano-SiO 2 The sol is pre-dispersed with 2.3g of TDI, 10g of propylene glycol polyoxypropylene ether, 0.45g of 1,4-butanediol and 1.5g of toluene in the presence of 0.02g of stannous octoate, and quickly poured into the reactor after stirring In one end of the reactor, the above system is heated for 50s for a short time, the heating temperature is 110°C, then the heating is stopped, and the monomer polymerization is completed by means of the thermal self-catalysis of the exothermic reaction, and the polyurethane and its components with good stability are prepared. Polyurethane nanocomposites. The decomposition temperature measured for this material is listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com