Chicken feather down fibre yarn and method for making same

A processing method and velvet fiber technology, applied in the field of textile yarn, can solve the problems of only being treated as garbage, waste, and failure to make the best use of everything, and achieve the effect of sufficient chicken feather raw materials, low cost, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of Chicken Down Fiber

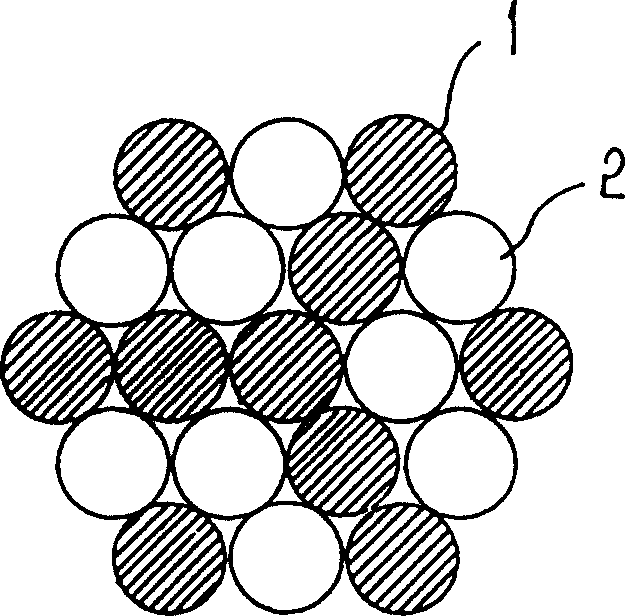

[0026] Take the washed flower-shaped chicken down and the soft single hairy branch at the root of the chicken feather sheet, and comb it in the improved carding machine. When carding, spray emulsified wool oil accounting for 2% of the raw material weight. The internal reciprocating cycle is combed 6 times to obtain curly chicken down single fibers 1, and the chicken down single fibers 1 are entwined and entangled with each other, and are ready for use.

Embodiment 2

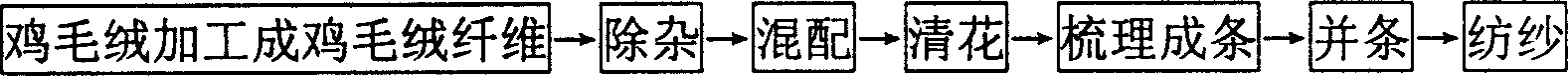

[0028] Processing of chicken down monofilament and wool down fiber blended yarn

[0029] Mixing: the chicken down single fiber processed in Example 1 is uniformly sprayed with an aqueous solution of 2% palm oil according to 80% and 20% wool fiber, and evenly mixed with 0.8% talcum powder, used The traditional opener opens twice in a row and seals it in a non-ventilated place for 24 hours.

[0030] Blowing: The mixed chicken down single fiber and wool fiber are further removed by traditional cleaning process, mixed evenly, and then rolled.

[0031] Carding into slivers: According to the traditional carding process, the rolled mixed fibers are made into slivers.

[0032] Draw frame: Use traditional draw frame for 5 consecutive draw frames to make it a qualified sliver for textile equipment.

[0033] Spinning: Twisting and spinning into yarn with traditional ring spinning equipment.

Embodiment 3

[0035] Processing of Chicken Down Fiber and Cotton Fiber Blended Yarn

[0036] Mixing: 65% of chicken plush fibers processed in Example 1 and 35% of cotton fibers are evenly mixed with 0.5% talcum powder, continuously opened twice with a traditional opener, and sealed for 20 days in a non-ventilated place. Hour.

[0037] All the other processes of blowing, carding into sliver, drawing, and spinning are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com