Method for recovering and reutilizing industrial waste salt and apparatus thereof

A technology of industrial waste salt and industrial salt, applied in the direction of alkali metal chloride, etc., can solve the problems of open-air stacking or direct discharge into rivers, waste of resources, environmental pollution, etc. The effect of improving the decomposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

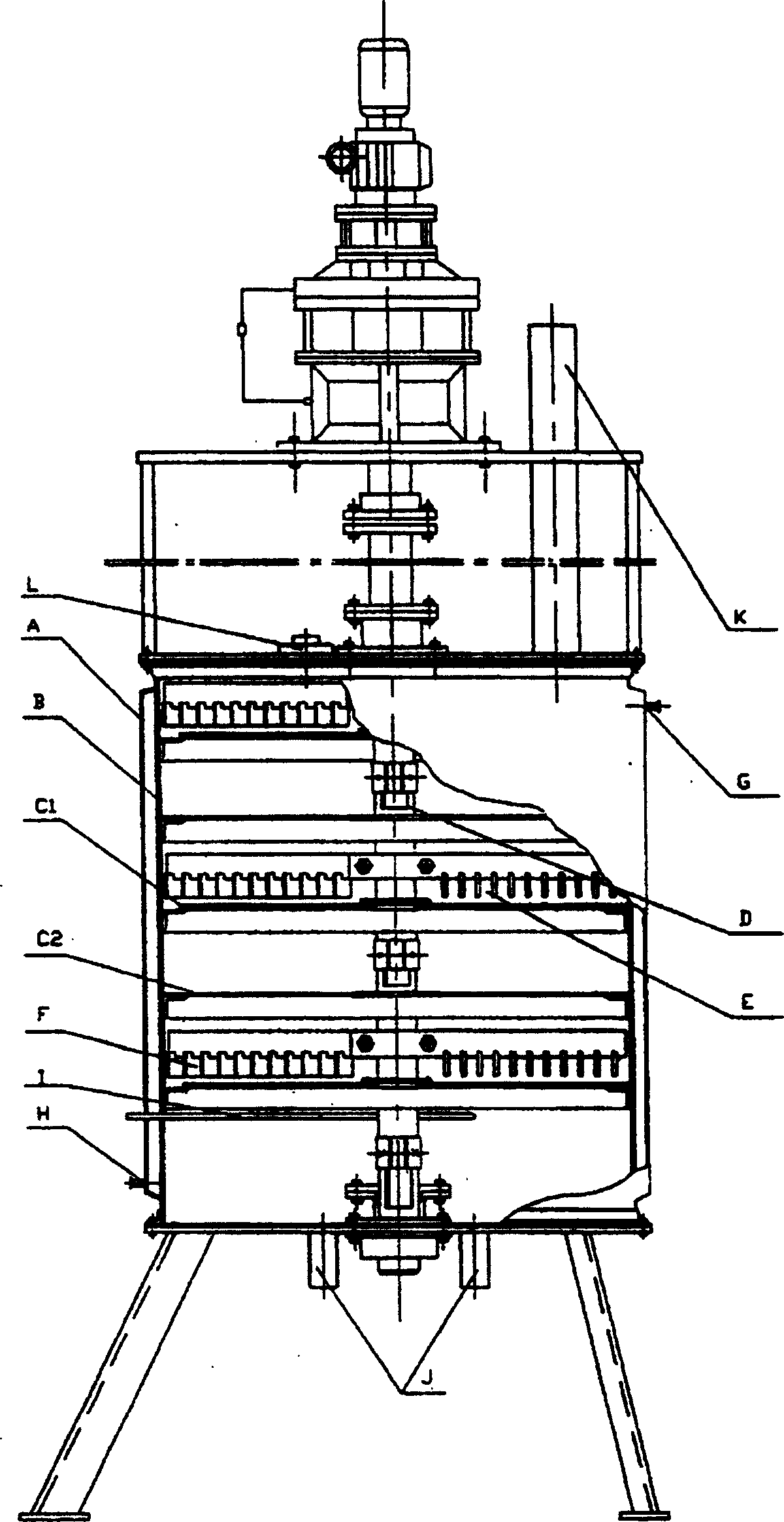

Image

Examples

example 1

[0006] Example 1: 100Kg of by-product salt (ammonium content 5800ppm) of the hydrazine hydrate production plant is continuously fed into the heating furnace, and the material stays for 4-8 hours. The furnace is maintained at 400-500 ° C, and hot air at 400-500 ° C is introduced. The product salt contains Ammonium 12.3ppm.

example 2

[0007] Example 2: 50Kg of by-product salt (ammonium content 5600ppm) of the hydrazine hydrate production plant is continuously fed into the heating furnace, the material stays for 6-12 hours, the furnace is maintained at 500-600 ° C, and hot air at 500-600 ° C is introduced, and the product salt contains Ammonium 9.1ppm.

example 3

[0008] Example three: 50Kg of by-product salt (phenol, ether content 2%) of furan phenol production plant, continuous feed into the heating furnace, the material stays for 8-12 hours, maintains 450-550 ° C in the furnace, feeds hot air at 450-550 ° C, the product The content of phenol and ether in the salt is 7.8ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com