Synthesis process of nano zinc oxide material

A technology of zinc oxide nanometer and synthesis method, which is applied in the field of zinc oxide nanometer material synthesis, can solve problems such as uneven morphology and agglomeration, and achieve the effects of uniform appearance, less demanding equipment requirements and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

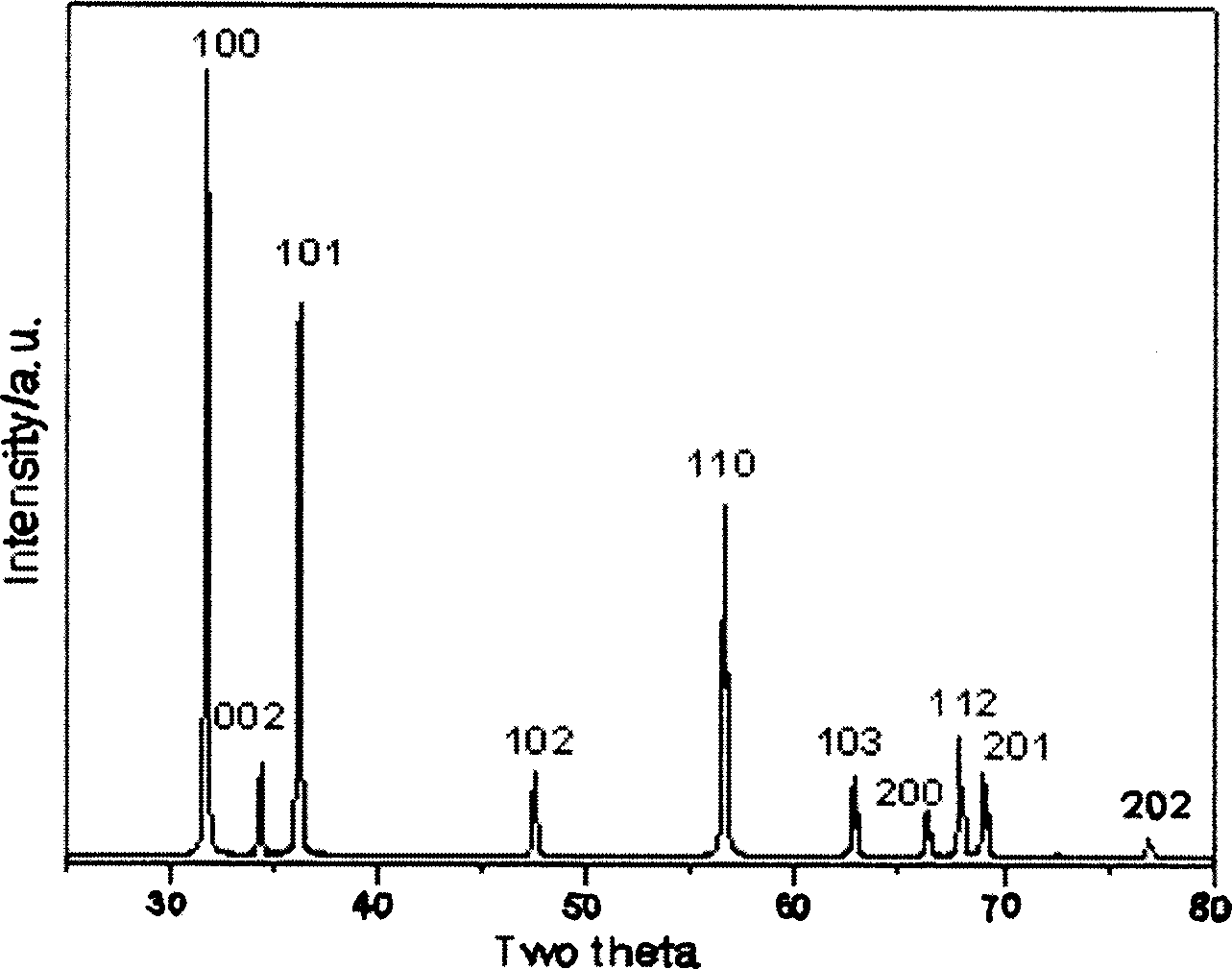

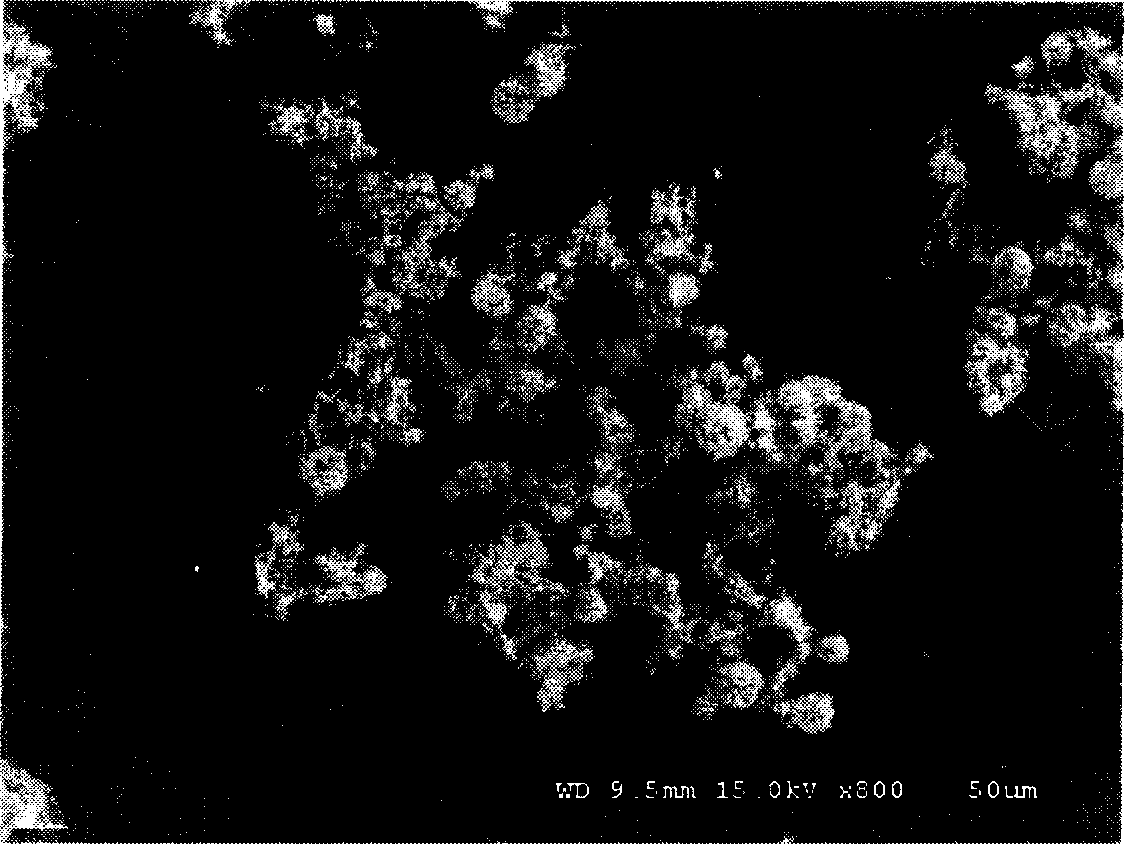

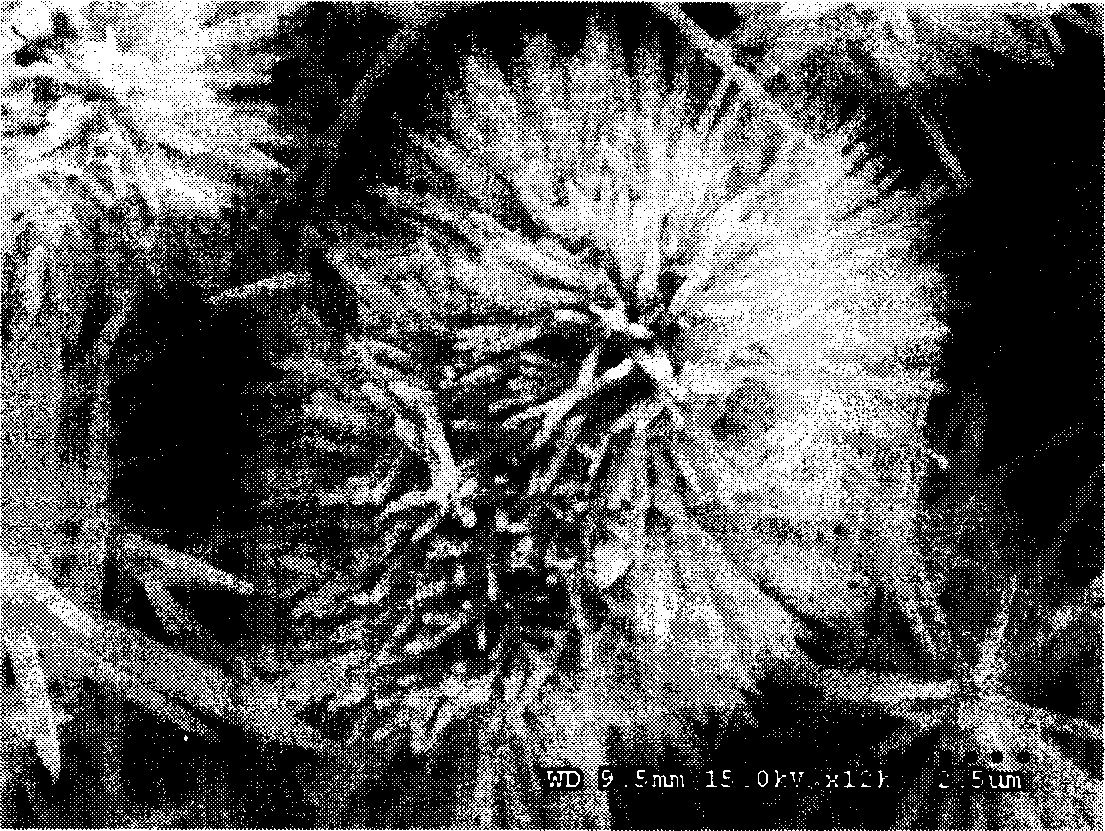

[0013] The potassium hydroxide that takes by weighing 0.005mol zinc nitrate and 0.05mol is placed in the beaker, forms transparent solution with stirring and dissolving with 15ml deionized water, then according to transparent solution: concentration is 20% soluble surfactant=100: 10 weight parts Add the sodium lauryl sulfate surfactant solution to the transparent solution, stir for 30 minutes, then move the above mixed solution into a closed reactor, react at 100°C for 24 hours, cool the closed reactor to room temperature, and then The resulting product was washed with deionized water and dried at 60 °C. The product was identified as hexagonal phase zinc oxide by X-ray powder diffraction; the morphology of the product was a chrysanthemum-shaped three-dimensional nanomaterial detected by SEM electron microscopy.

Embodiment 2

[0015] The lithium hydroxide that takes by weighing 0.005mol zinc acetate and 0.025mol is placed in the beaker, forms transparent solution with stirring and dissolving with 15ml deionized water, then according to transparent solution: concentration is 5% soluble surfactant=100: 3 weight parts Add cetyltrimethylammonium bromide surfactant solution to the transparent solution, stir for 20 minutes, then transfer the above mixed solution into a closed reactor, react at 180°C for 12 hours, and cool the closed reactor to room temperature, and then the resulting product was washed with ethanol and dried at 90°C. The product was identified as hexagonal phase zinc oxide by X-ray powder diffraction; the morphology of the product was a chrysanthemum-shaped three-dimensional nanomaterial detected by SEM electron microscopy.

Embodiment 3

[0017] The sodium hydroxide that takes by weighing 0.005mol zinc sulfate and 0.1mol is placed in beaker, forms transparent solution with 15ml deionized water stirring and dissolving, then according to transparent solution: concentration is 30% soluble surfactant=100: 20 weight parts Add di(ethyl-ethylhexyl)sodium sulfosuccinate surfactant solution to the transparent solution, stir for 40 minutes, then transfer the above mixed solution into a closed reactor, react at 220°C for 1 hour, and close the closed reactor. The reactor was cooled to room temperature, and then the resulting product was washed with deionized water, and the wash was dried at 50°C. The product was identified as hexagonal zinc oxide by X-ray powder diffraction; SEM electron microscopy detected that the product was a chrysanthemum-shaped three-dimensional nanomaterial

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com