Mask, method of manufacturing the same, method of forming thin film pattern, method of manufacturing electro-optical device

A technology of thin film pattern and manufacturing method, which is applied in the direction of electric light source, lighting device, electroluminescent light source, etc., can solve the problems such as the inability to manufacture evaporation masks and the increase of error accumulation value, and achieve the purpose of suppressing the amount of etching and reducing The effect of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] A mask according to an embodiment of the present invention will be described below with reference to the drawings.

[0084] (manufacturing of masks)

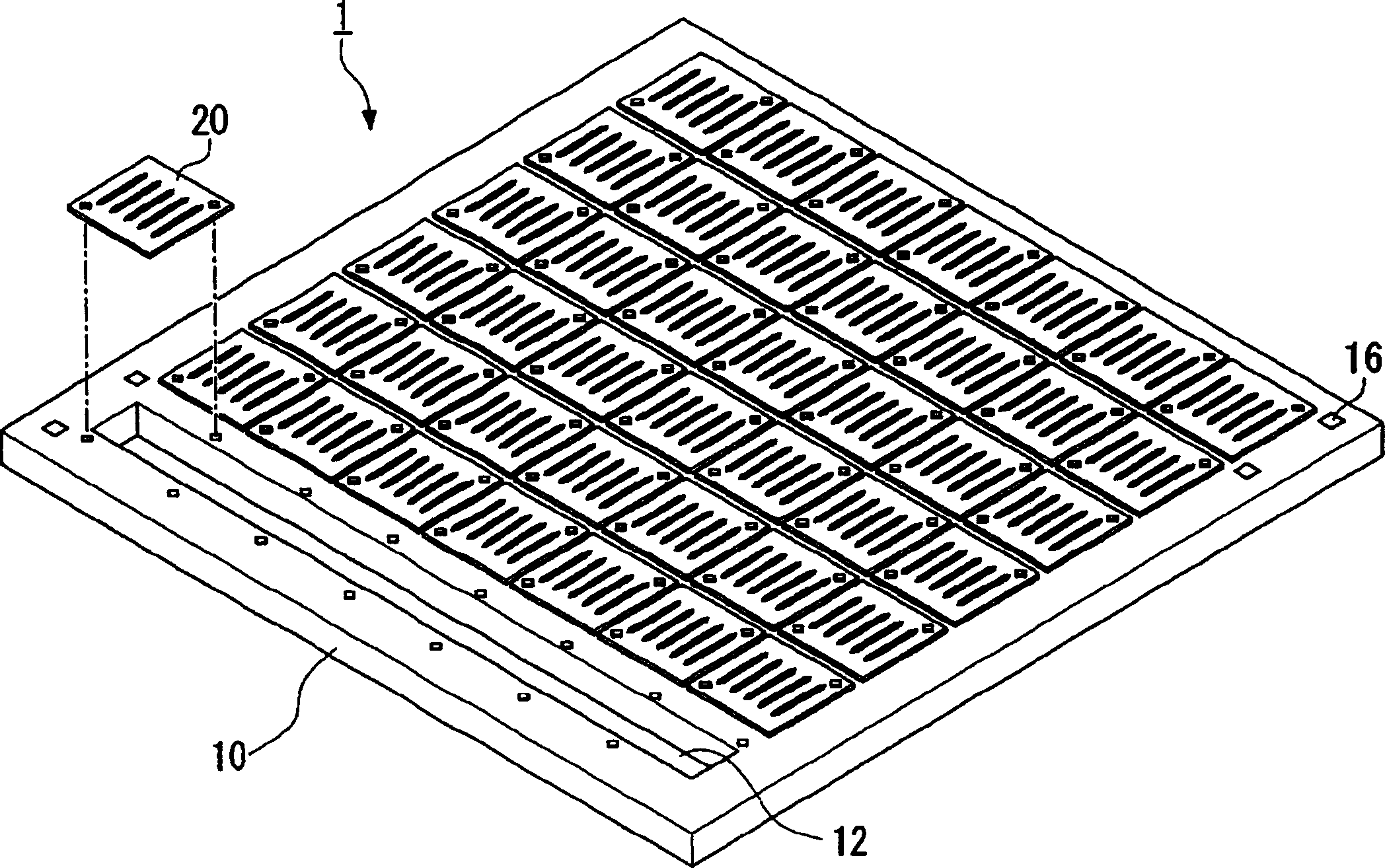

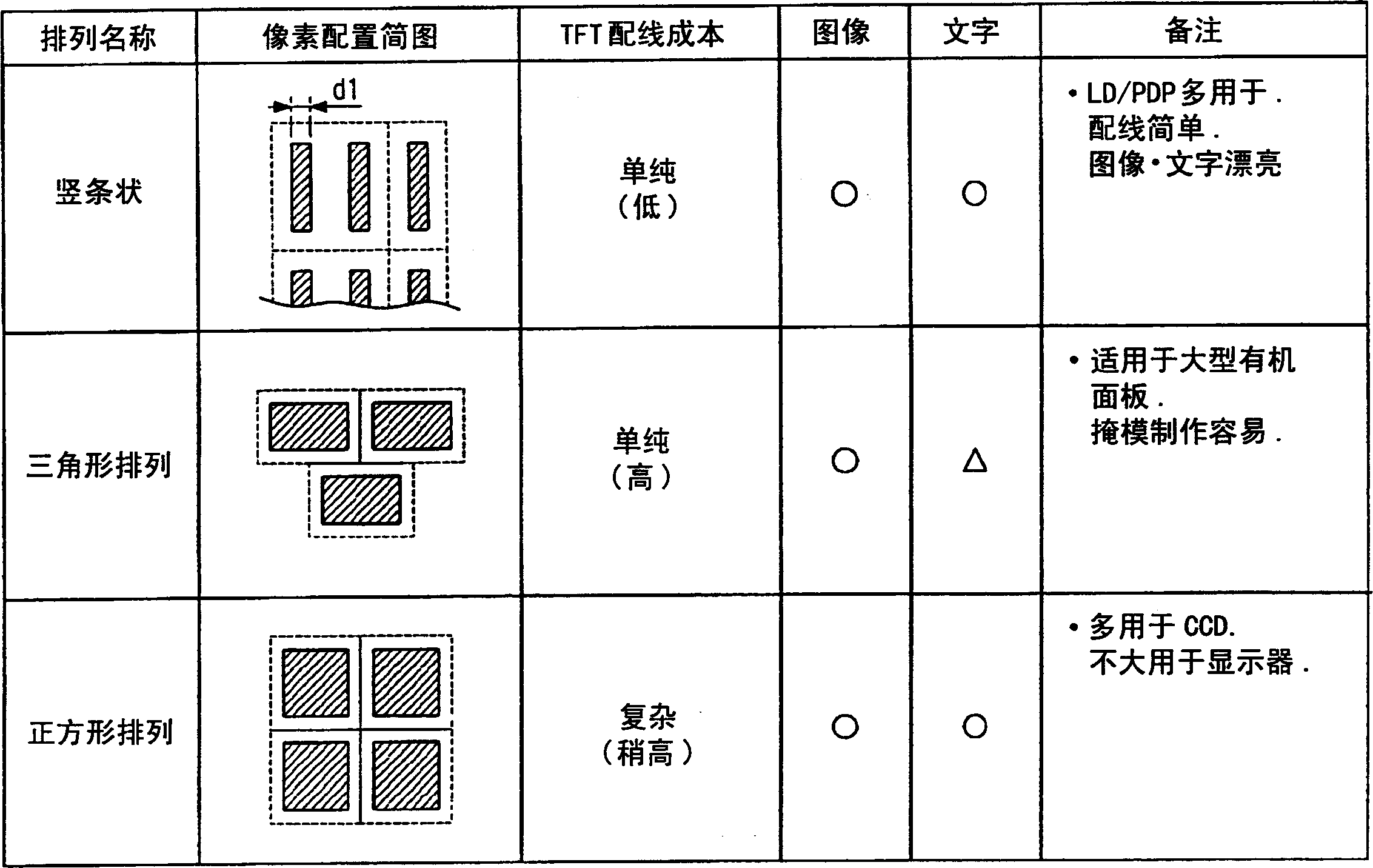

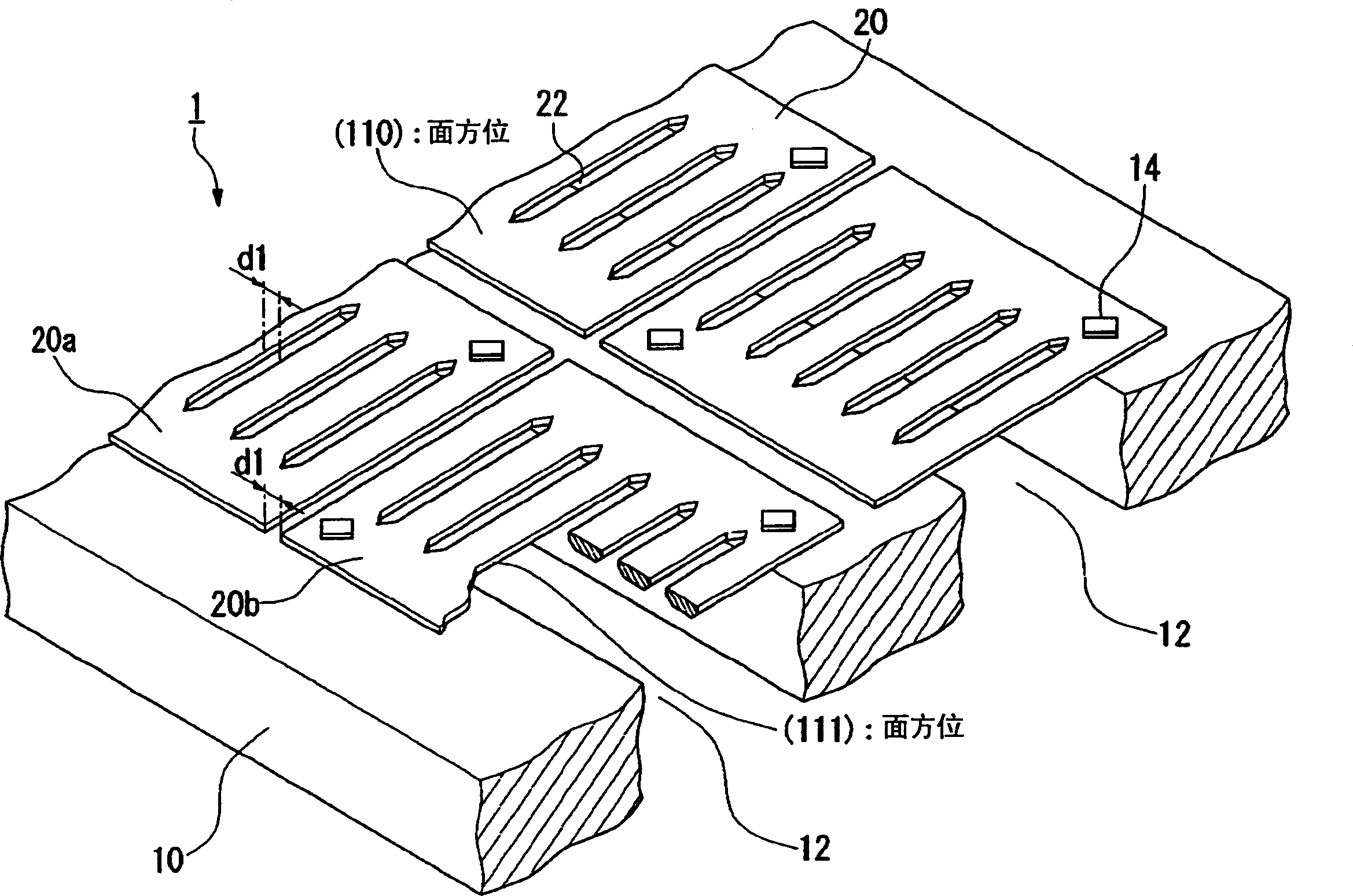

[0085] figure 1 It is a schematic perspective view which shows the mask which concerns on embodiment of this invention. figure 2 is used to express figure 1 Diagram of an example of a pixel pattern arrangement formed by the mask shown. image 3 Yes figure 1 An enlarged perspective view of the main part of the mask shown. The mask 1 of this embodiment can be used as a vapor deposition mask, for example.

[0086] The mask 1 has a configuration in which a plurality of chips 20 are mounted on a support substrate 10 as a base substrate. In this embodiment, the chip 20 is made of silicon. Moreover, the chip 20 can also be made of metal materials. Each chip 20 is arranged so as to be bonded to the substrate 10 . Further, mask alignment marks 16 are formed on the support substrate 10 . The mask alignment mark 16 is a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com