Foam ceramic annular filler

A ceramic foam and ring-shaped technology, which is applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low mass transfer efficiency, large specific surface area, and high mass transfer efficiency, and achieve improved The effect of large surface area, specific surface area, and low bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

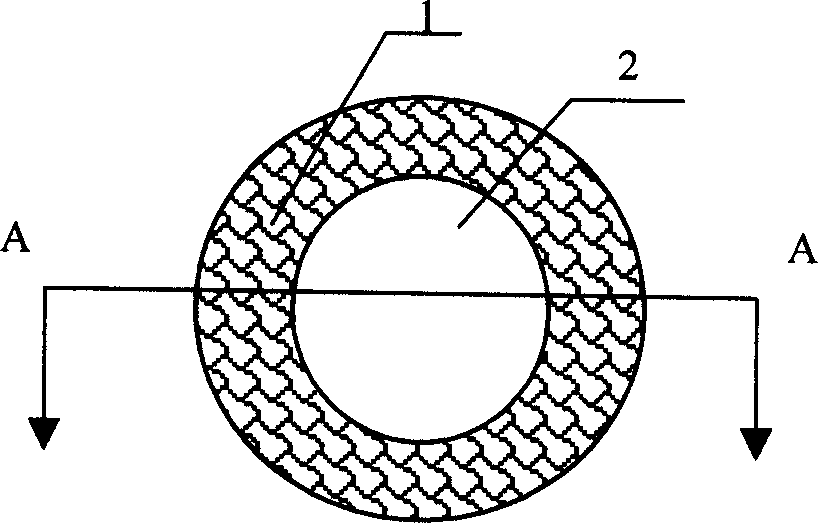

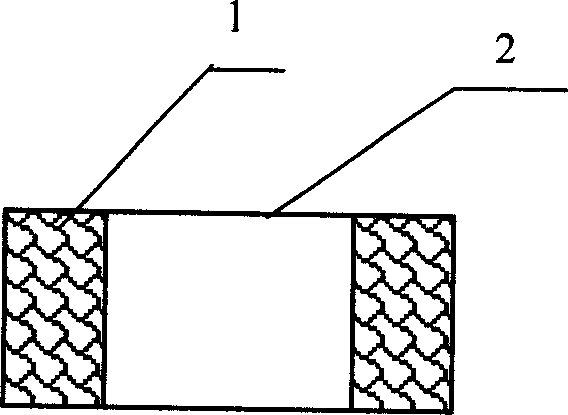

[0020] Ф25mm ceramic foam annular filler is used, the ceramic foam pore diameter of the torus (1) is 2mm, the diameter of the inner cavity (2) is 10mm, the packing height is 7.5mm, the ratio of height to diameter is 0.3, and the ratio of inner and outer diameters is 0.4.

[0021] Such as figure 1 , figure 2 As shown, the torus (1) of the ceramic foam ring packing is made of foam ceramics and has a unique three-dimensional network structure, which is similar to the structural characteristics of the composite expanded mesh packing. These small holes communicate with the packing surface and have a large specific surface area. Bulk density is small.

[0022] The middle of the packing structure is a cylindrical cavity (2). Such an open packing structure is conducive to further increasing the void ratio of the packing, reducing flow resistance, and at the same time facilitating the renewal of the packing surface and improving the mass transfer efficiency.

[0023] The packing str...

Embodiment 2

[0033] Ф50mm ceramic foam annular filler is used, the ceramic foam pore diameter of the torus (1) is 5mm, the diameter of the inner cavity (2) is 30mm, the packing height is 20mm, the ratio of height to diameter is 0.4, and the ratio of inner and outer diameters is 0.6.

[0034] The porosity of the ceramic foam filler of the present invention is as high as 94%, which is higher than that of Pall rings and saddle rings of the same material, and the specific surface area is 2156m 2 / m 3 , bulk density is only 204kg / m 3. The fluid resistance (i.e. the pressure drop of the packing layer) of the ceramic foam packing of the present invention is less than several other packings of the same size, which is 54% to 67% of the ceramic Pall ring and the saddle ring, and is 54% to 67% of the stainless steel Pall ring and the saddle ring. 67-75%, which indicates that the energy consumption of fluid passing through the packing layer is reduced. Compared with the Pall ring and the saddle rin...

Embodiment 3

[0036] Ф50mm ceramic foam ring packing, the ring body (1) has a ceramic foam hole diameter of 4mm, the inner cavity (2) has a diameter of 40mm, the packing height is 30mm, the ratio of height to diameter is 0.6, and the ratio of inner and outer diameters is 0.8.

[0037] The porosity of the ceramic foam filler of the present invention is 94%, which is higher than the Pall ring and saddle ring of the same material, and the specific surface area is 2016m 2 / m 3 , bulk density is only 195kg / m 3 . The fluid resistance (i.e. the pressure drop of the packing layer) of the ceramic foam filler of the present invention is less than several other fillers of the same size, which is 52% to 68% of the ceramic Pall ring and the saddle ring, and 52% to 68% of the stainless steel Pall ring and the saddle ring. 71-85%, which indicates that the energy consumption of fluid passing through the packing layer is reduced. Compared with the Pall ring and the moment saddle ring, the mass transfer u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com