Acoustic surface wave delay line with single-phase single structure

A surface acoustic wave delay and one-way structure technology, applied in the direction of electrical components, impedance networks, etc., can solve problems such as inappropriateness, large loss, and increased system power consumption, and achieve improved frequency stability, good temperature characteristics, and reduced insertion The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to have a more comprehensive understanding of the present invention, and to understand additional objects and advantages of the present invention, the present invention will now be described in detail with reference to the accompanying drawings and embodiments.

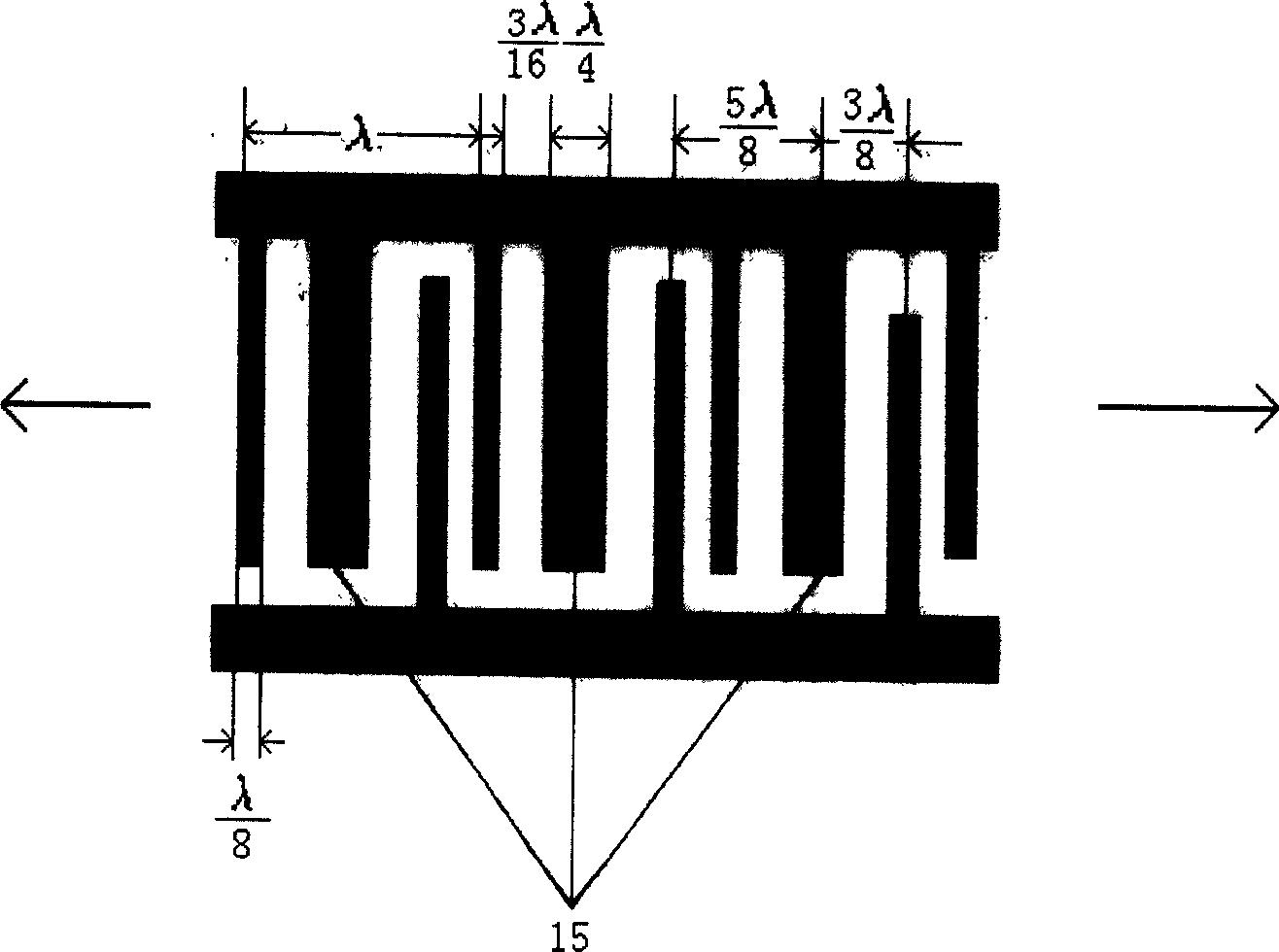

[0035] Figure 7 Shown the embodiment of the SAW delay line with EWC / SPUDT structure of the present invention, this SAW delay line 6 is made of a rectangular piezoelectric substrate 28 and is arranged on its upper surface along the two lengths that propagate along the sound wave direction and is 100 times The interdigital transducers 26 and 27 of the EWC / SPUDT structure of the wavelength are composed of, the distance between the two interdigital transducers is 150 times the wavelength, and the acoustic aperture is 100 times the wavelength, wherein the electrode thickness of the interdigital transducer is 1200 angstroms, the electrode of the interdigital transducer is a gold electrode, and the piezoelec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com