Process for preparing aperture-controllable alumina template

An alumina template and pore size technology, applied in the field of electrochemistry, can solve the problems of complicated experiments, narrow preparation range, and less description of the template preparation process, and achieve the effect of simple method and low product cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

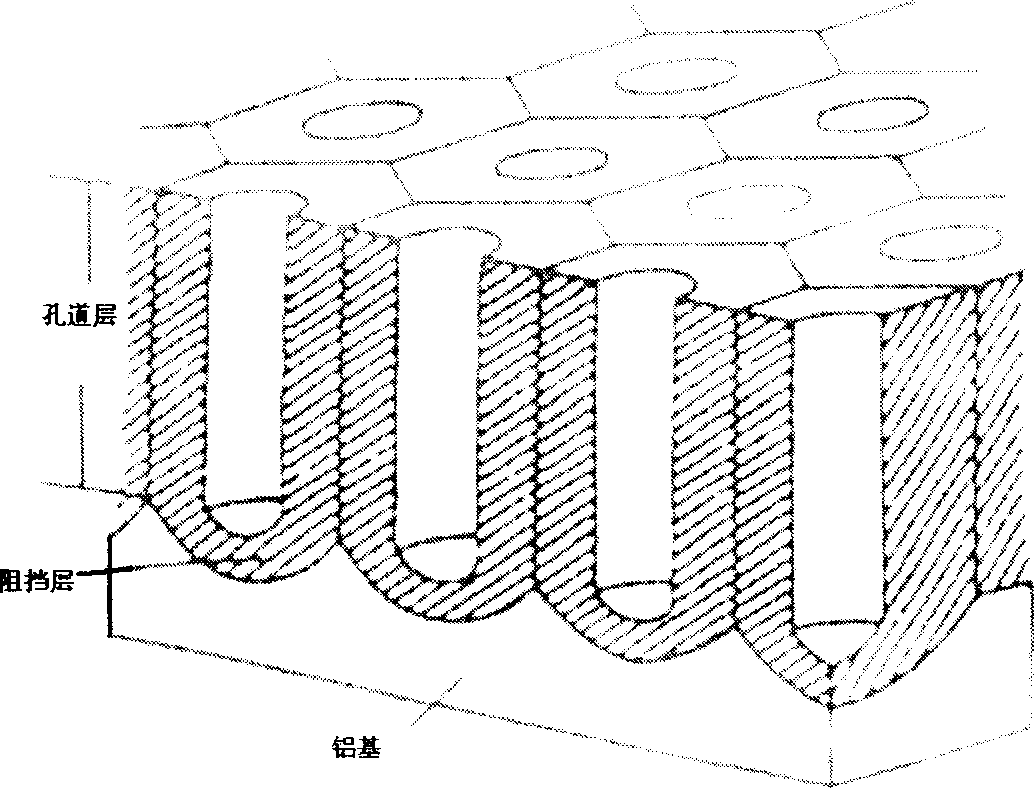

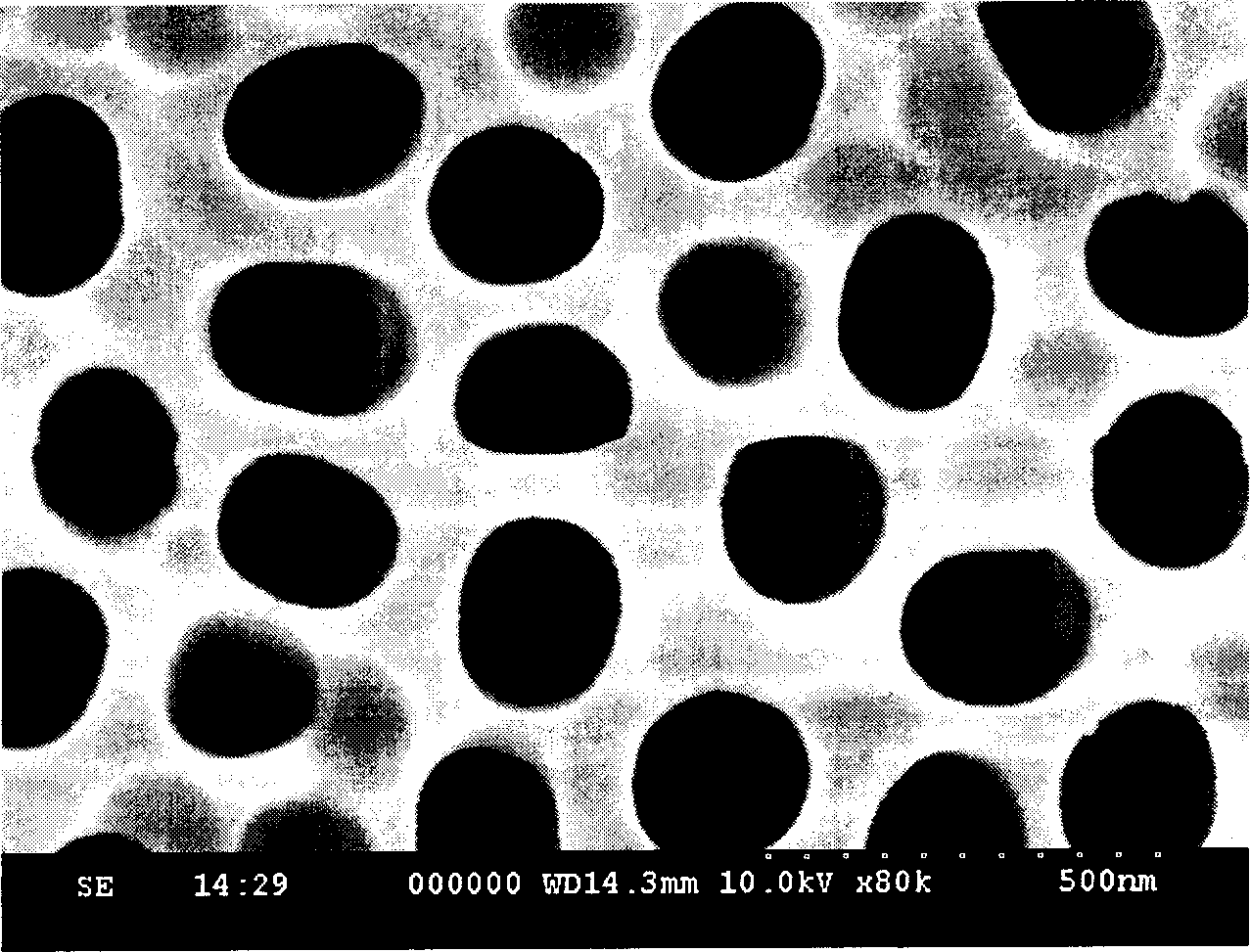

Embodiment 1

[0022] Using high-purity aluminum (99.00~99.999%) as raw material, ultrasonic treatment in acetone solution for 5~20 minutes to remove organic contaminants on the surface, and then at a voltage of 10 volts, aluminum sheet as anode, platinum sheet as cathode (aluminum sheet and Platinum sheet area ratio 2-20), electrolyze in a mixed solution of analytically pure perchloric acid and absolute ethanol (volume ratio 0.2-0.25) for about 15-20 minutes to remove oxides on the surface to obtain a bright aluminum sheet. Under the voltage of 20 volts, with 10-20wt% of H 2 SO 4 It is mixed with anhydrous ethanol in a volume ratio of 0.5 to 1 and used as an electrolyte. The electrolyte is magnetically stirred and electrolyzed at room temperature for 2 to 4 hours. A water bath is used for the electrolysis process. Use HCl-CuCl 2 Mixture (CuCl 2 The concentration is 0.1~0.2 mol / L, the mass ratio of HCl is 20~36%, the two are mixed in equal volume) to remove the aluminum base, the reaction time i...

Embodiment 2

[0024] Using high-purity aluminum (99.00~99.999%) as raw material, ultrasonic treatment in acetone solution for 5~20 minutes to remove organic contaminants on the surface, and then at a voltage of 10 volts, aluminum sheet as anode, platinum sheet as cathode (aluminum sheet and Platinum sheet area ratio 2-20), electrolyze in a mixed solution of analytically pure perchloric acid and absolute ethanol (volume ratio 0.2-0.25) for about 15-20 minutes to remove oxides on the surface to obtain a bright aluminum sheet. Under the voltage of 40 volts, with 0.3 mol / L of H 2 C 2 O 4 It is mixed with anhydrous ethanol at a volume ratio of 0.5 to 1 and used as an electrolyte. The electrolyte is magnetically stirred and electrolyzed at room temperature for 3 to 8 hours. A water bath is used for the electrolysis process. Use HCl-CuCl 2 Mixture (CuCl 2 The concentration is 0.1-0.2 mol / L, the mass ratio concentration of HCl is 20-36%, and the two are mixed in equal volume) to remove the aluminum bas...

Embodiment 3

[0026] Using high-purity aluminum (99.00~99.999%) as raw material, ultrasonic treatment in acetone solution for 5~20 minutes to remove organic contaminants on the surface, and then at a voltage of 10 volts, aluminum sheet as anode, platinum sheet as cathode (aluminum sheet Platinum sheet area ratio 2-20), electrolyze in a mixed solution of analytically pure perchloric acid and absolute ethanol (volume ratio 0.2-0.25) for about 15-20 minutes to remove oxides on the surface to obtain a bright aluminum sheet. At a voltage of 60 volts, with 0.3 mol / L of H 2 C 2 O 1It is mixed with anhydrous ethanol in a volume ratio of 0.5 to 1 and used as an electrolyte. The electrolyte is magnetically stirred and electrolyzed at room temperature for 4 to 10 hours. A water bath is used for the electrolysis process. Use HCl-CuCl 2 Mixture (CuCl 2 The concentration is 0.1-0.2 mol / L, the mass ratio concentration of HCl is 20-36%, and the two are mixed in equal volume) to remove the aluminum base by reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com