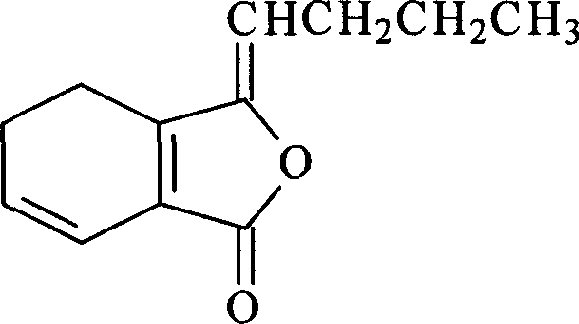

Combination of ligusticum lactone, preparation method and application

A technology of ligustilide and its composition, which is applied in the field of ligustilide composition and its preparation, can solve the problems of instability of ligustilide, difficulty in preparation and inability to learn from it, and reduce microvascular leakage, reduce Mortality rate, effect of shortening ear-eye cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 295g of ligustilide was dissolved in 2680g of soybean oil, and conventional soft capsule preparation techniques were used to prepare soft capsules with a loading capacity of 250 mg. After being placed at room temperature for one and a half years, it was shown that the contents were basically stable. The results are shown in Table 3.

[0042] placement conditions

Embodiment 2

[0044] Add 5kg of soybean oil (by vacuum pumping) into the batching tank, heat up to 80°C, add 0.6kg of lecithin, stir for 5-8 minutes, add 250g of ligustilide after the lecithin is completely dispersed, and turn on the circulation pump. Mix the oil and glycerin in the batching tank in proportion, and start high-speed stirring. Add sodium hydroxide solution (1moL / L) to adjust the pH to 6.0-7. Stop stirring, add filtered water for injection to the full amount of 50000ml, stir evenly, it is primary emulsion, measure glycerin content, pH value (glycerol content 95%-105%, pH value: 6.0-7.0). Cool the colostrum to 55-60°C, start the low-pressure homogenizer, let the colostrum circulate and homogenize in the machine, start the high-pressure homogenizer, let the emulsion enter the machine, circulate and homogenize, repeat homogenization 10 times. After the first 9 times of homogenization, the emulsion is cooled to about 50-55°C through a heat exchanger. After the 10th time of homoge...

Embodiment 3

[0047] 60g of ligustilide is dissolved in 3000g of soybean oil, and the technology is used to prepare soft capsules with a filling capacity of 250mg. After being placed at room temperature for one and a half years, it was shown that the contents were basically stable. The results are shown in Table 5.

[0048] placement conditions

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com