Method for extracting galanthamine from raw materials of genera of lycoris radiata or snowdrop

A technology of galantamine and snowdrops, applied in the field of extracting galantamine, can solve the problems of low extraction rate, poor selectivity, and many extraction and separation steps, and achieve environmental friendliness, strong solubility, extraction rate and selectivity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The content of galantamine is 1.48×10 -2 % Lycoris as raw material, raw material crushed particle size is 60 mesh, ultrasonic power 200 watts treatment for 0.5 hours, after drying, put 52 grams of Lycoris raw material into the extractor, SC-CO 2 The operating conditions for extracting galantamine: the extraction temperature is 70°C, the pressure is 30MPa, CO 2 The amount is 110 times of the raw material amount, and the amount of entrainer ethanol solvent is CO 2 The water content in ethanol is 8%, and the extraction time is 1 hour. Release the product from the gas-liquid separator for detection and analysis, and the extraction rate of galantamine is 98%.

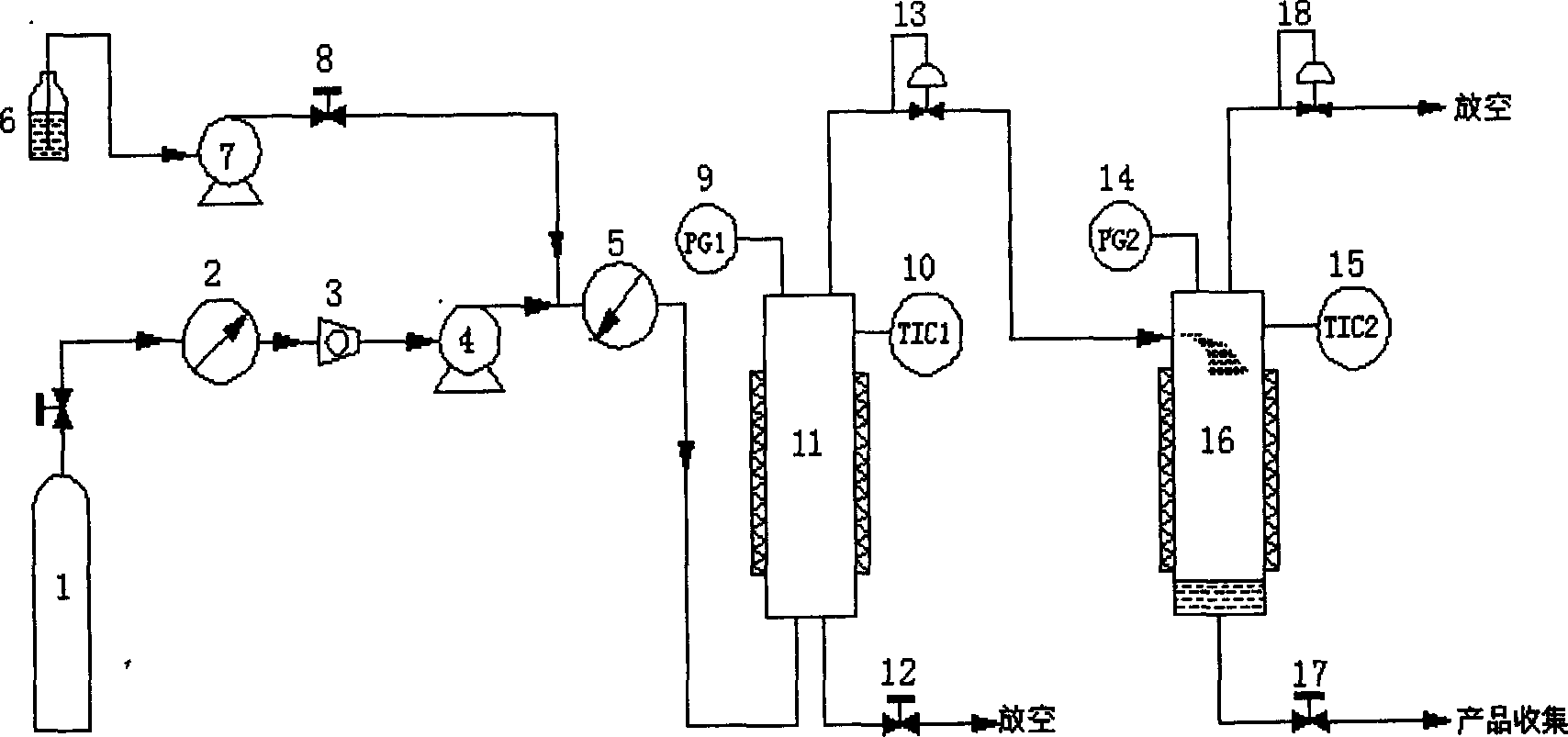

[0033] This embodiment adopts figure 1 The process shown, with supercritical CO 2 The operation steps of extracting galantamine with polar entraining agent are as follows:

[0034] (1) put into the pretreated raw material of 52 grams in the extractor 11;

[0035] (2) Turn on the device control system and set the...

Embodiment 2

[0046] With galantamine content of 0.3% snow lotus as raw material, the crushed particle size of the raw material is 40 mesh, and the ultrasonic power is 300 watts for 1 hour. After drying, 48 grams of snow lotus raw material is put into the extractor. In the extractor, according to figure 1 The shown SCFE extracts the technical process of galantamine to operate, and the operation steps are as described above, and SC-CO 2 The operating conditions for extracting galantamine are as follows:

[0047] The extraction temperature is 50°C, the pressure is 35MPa, CO 2 The amount is 50 times that of the raw material, and the amount of entrainer methanol solvent is CO 2 The water content in methanol is 5%, and the extraction time is 3 hours. Release the product from the gas-liquid separator for detection and analysis, and the extraction rate of galantamine is 92%.

Embodiment 3

[0049] The content of galantamine is 1.48×10 -2 % Lycoris as raw material, raw material crushed particle size is 60 mesh, ultrasonic power 200 watts treatment for 0.5 hours, after drying, put 52 grams of Lycoris raw material into the extractor, SC-CO 2 The operating conditions for extracting galantamine: the extraction temperature is 70°C, the pressure is 30MPa, CO 2 The amount is 110 times that of the raw material, and the extraction time is 4 hours. Release the product from the gas-liquid separator for detection and analysis, and the extraction rate of galantamine is 85%.

[0050] This embodiment adopts figure 1 The process shown, with supercritical CO 2 The operation steps of extracting galantamine are as follows:

[0051] (1) put into the pretreated raw material of 49 grams in the extractor 11;

[0052] (2) Turn on the device control system and set the CO 2 The cooling temperature of cooler 2 is 30°C, the CO of mass flow meter 3 2 The flow rate is 14700 grams, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com