Compound rapid forming method and device by integration of light solidification and fusion sediment

A fused deposition forming and fused deposition technology, which is applied in the field of composite rapid prototyping methods and devices integrating photocuring and fused deposition, can solve the problems of high production cost, affecting the precision of mold manufacturing, not meeting the RPM production capability and the performance of prototype parts, etc. , to achieve the effect of improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

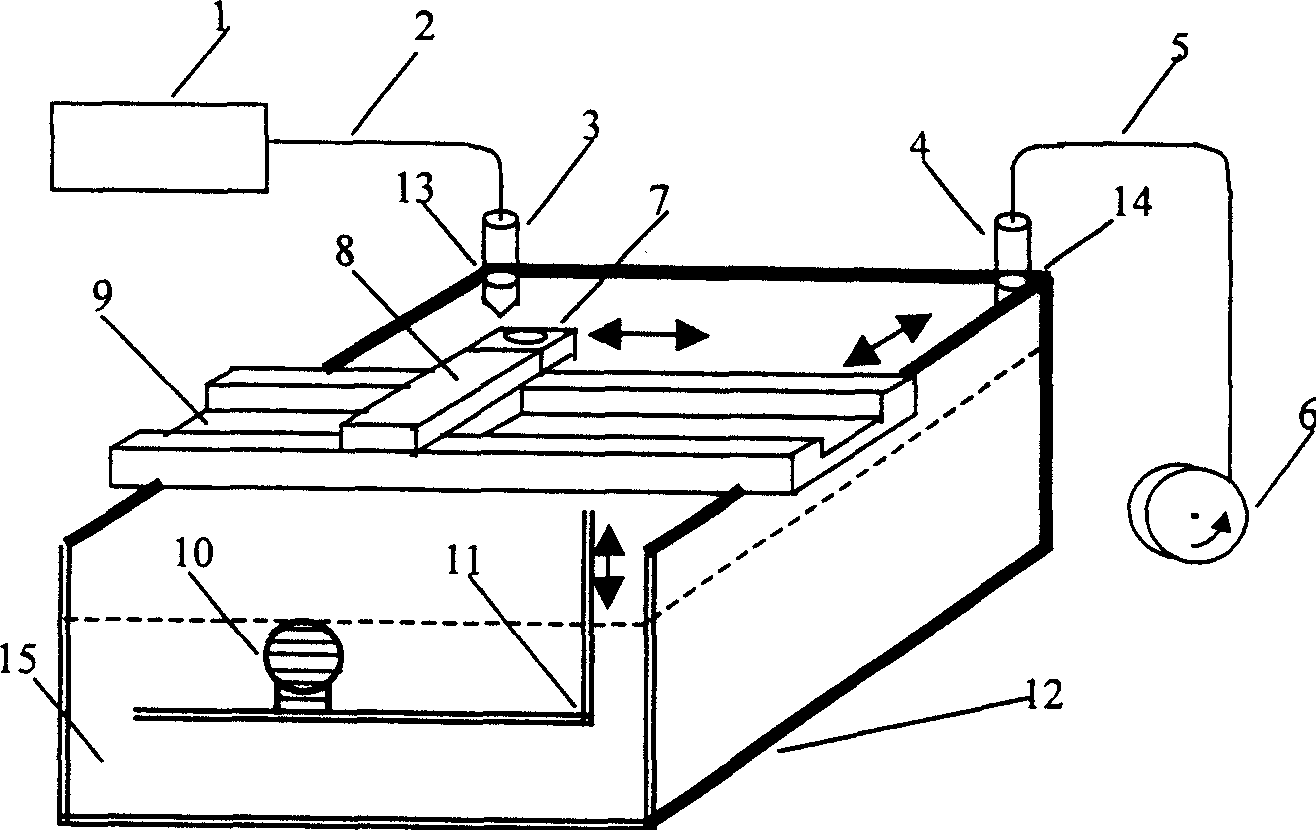

[0053] A preferred embodiment of the present invention is:

[0054] The structure of the composite rapid prototyping device integrated with photocuring and fused deposition:

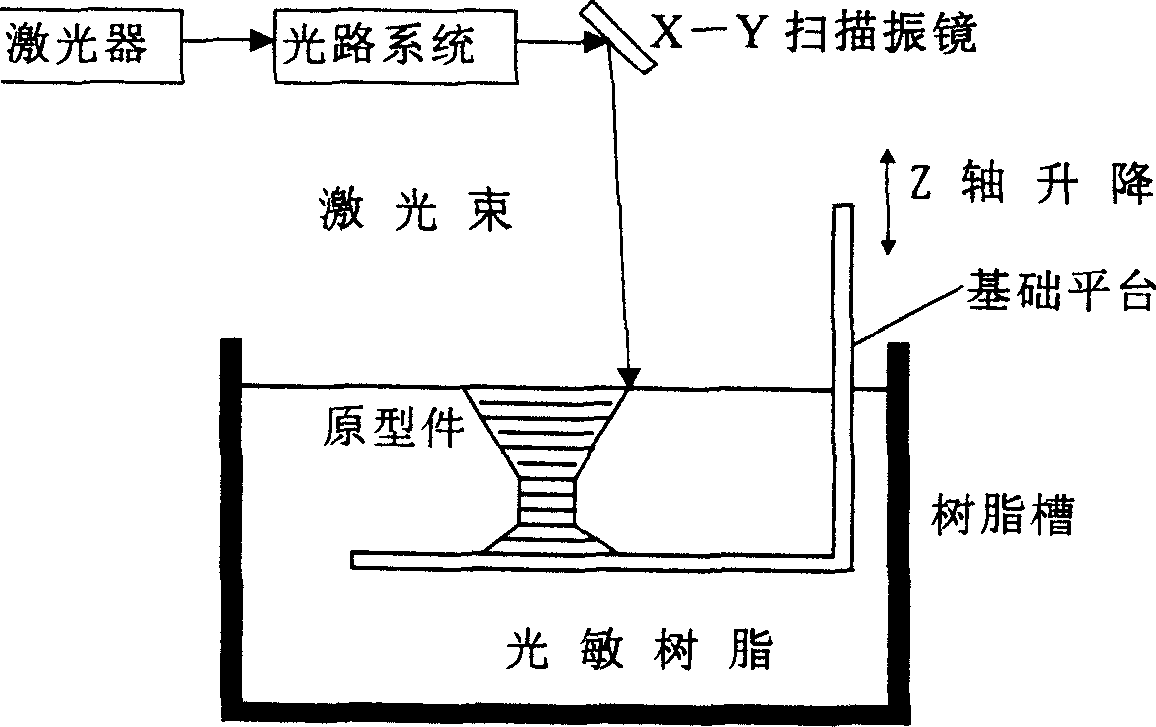

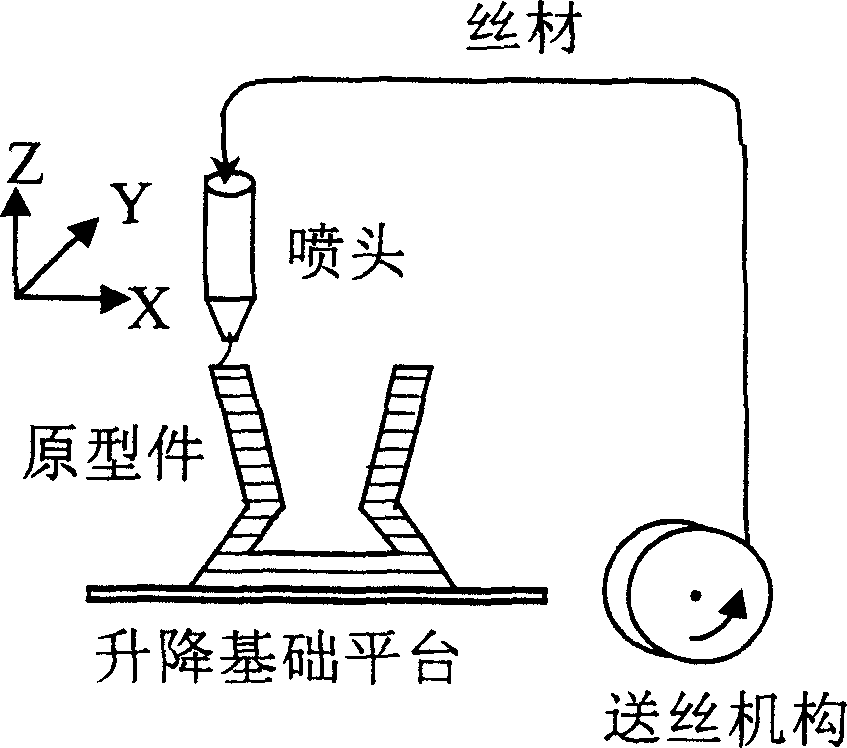

[0055] This project integrates the existing light-curing SL under the framework of CNC machining center (principle such as figure 1 shown) and fused deposition modeling FDM (principle as figure 2 (shown) process, develop a method of manufacturing a three-dimensional physical entity of a predetermined shape by continuously forming multi-layer materials according to the required graphics on the basic platform, the basic realization mechanism includes a base platform, X-Y plane motion mechanism, FDM forming head system, SL Forming head system, automatic switching system between FDM forming head and SL forming head, computer control system, such as image 3 with Image 6 shown.

[0056] (1) image 3 Among them, the SL forming head system includes a light source 1, an optical path system 2 composed of o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com