Amorphous diamond wear proof protective layer of heat-sensitive printing head and its preparing method

A thermal print head, amorphous diamond technology, applied in printing and other directions, can solve the problems of poor bonding, poor wear resistance, and high stress on the wear-resistant protective layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

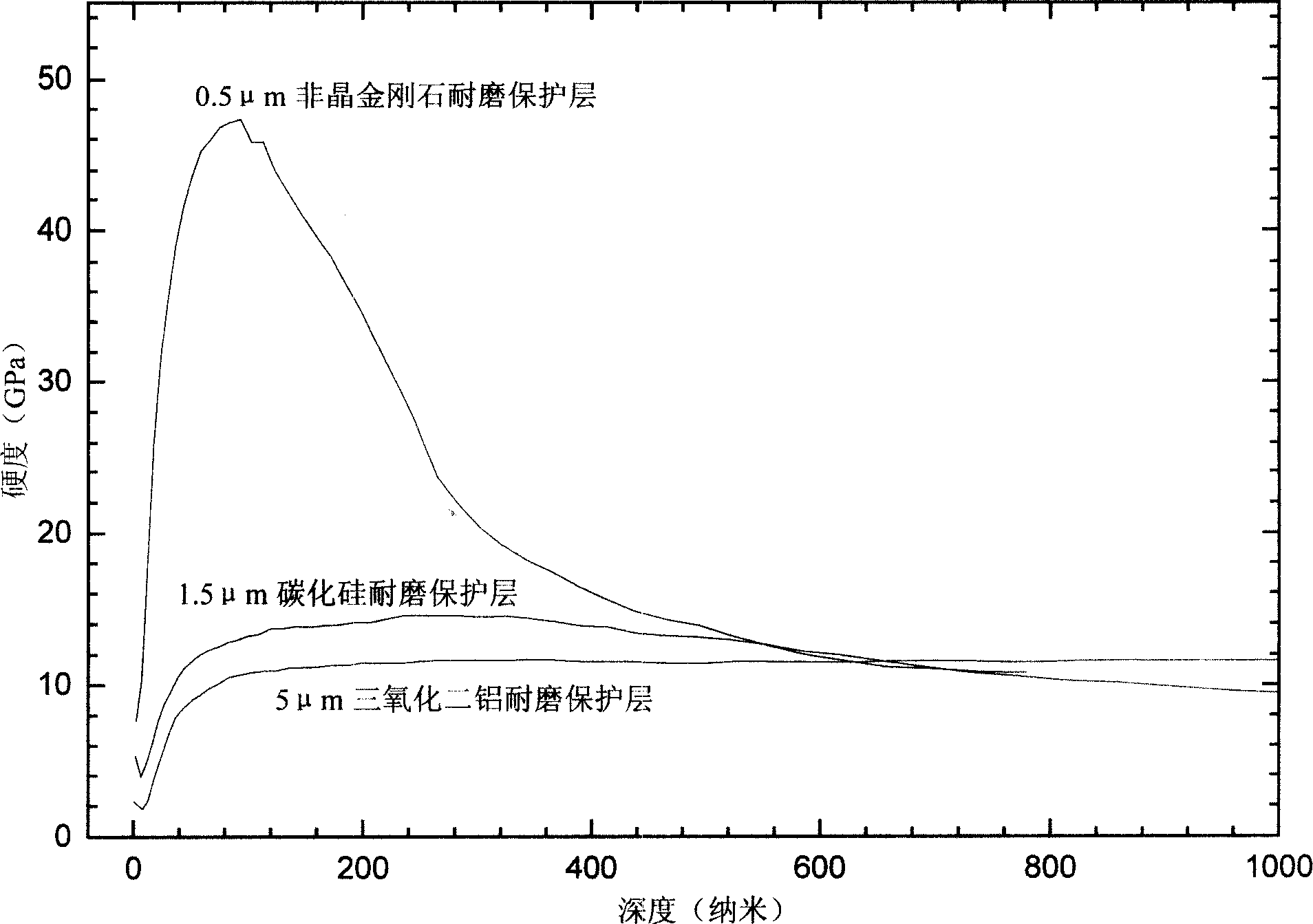

[0005] Specific embodiment one: the amorphous diamond wear-resistant protective layer of the thermal print head in this specific embodiment utilizes the filtered cathode vacuum arc system to deposit an amorphous diamond film on the surface of the thermal print head, and the amorphous diamond film The thickness is 0.3 ~ 2μm. The filtered cathode vacuum arc system is used to deposit amorphous diamond film, which has large deposition area, fast deposition speed, high film quality, low deposition temperature and pure surface.

specific Embodiment approach 2

[0006] Specific embodiment two: adopt the step of the preparation method of the amorphous diamond wear-resistant protection layer of the thermal print head of filtering cathodic vacuum arc system to comprise: 1, cleaning: will need to prepare the thermal print head of wear-resistant protective layer with acetone Clean in an ultrasonic cleaning machine, take it out and dry it with a hair dryer; 2. Marking: Use a marker pen to mark and cover the connection between the thermal print head and the drive circuit, and then install it on the substrate chuck of the filtered cathode vacuum arc system Put the deposition surface of the wear-resistant protective layer of the thermal print head to the etching work area of the vacuum chamber, and vacuumize; 3. Etching: the background vacuum degree is 1.5 to 2.5×10 -6 During Torr, inject argon with a purity of 99.99% to raise the vacuum to 1.0-4.0×10 -4 Torr, using a Kaufman ion gun to etch the deposition surface of the wear-resistant prote...

specific Embodiment approach 3

[0007] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the cleaning time in the ultrasonic cleaning machine in step 1 is 15 minutes. Other steps are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com