Electrostatic nano powder coating without chromization and phosphorization and its preparing method

A nano-powder and electrostatic spraying technology, which is applied in the field of nano-materials and chemical electrostatic powder coatings, and nano-technology, can solve the problems of endangering life and health, urban development, lack of anti-corrosion effect, and increasing industrial costs, so as to increase technical performance and use. function, eliminate environmental pollution and harm to the human body, and promote development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

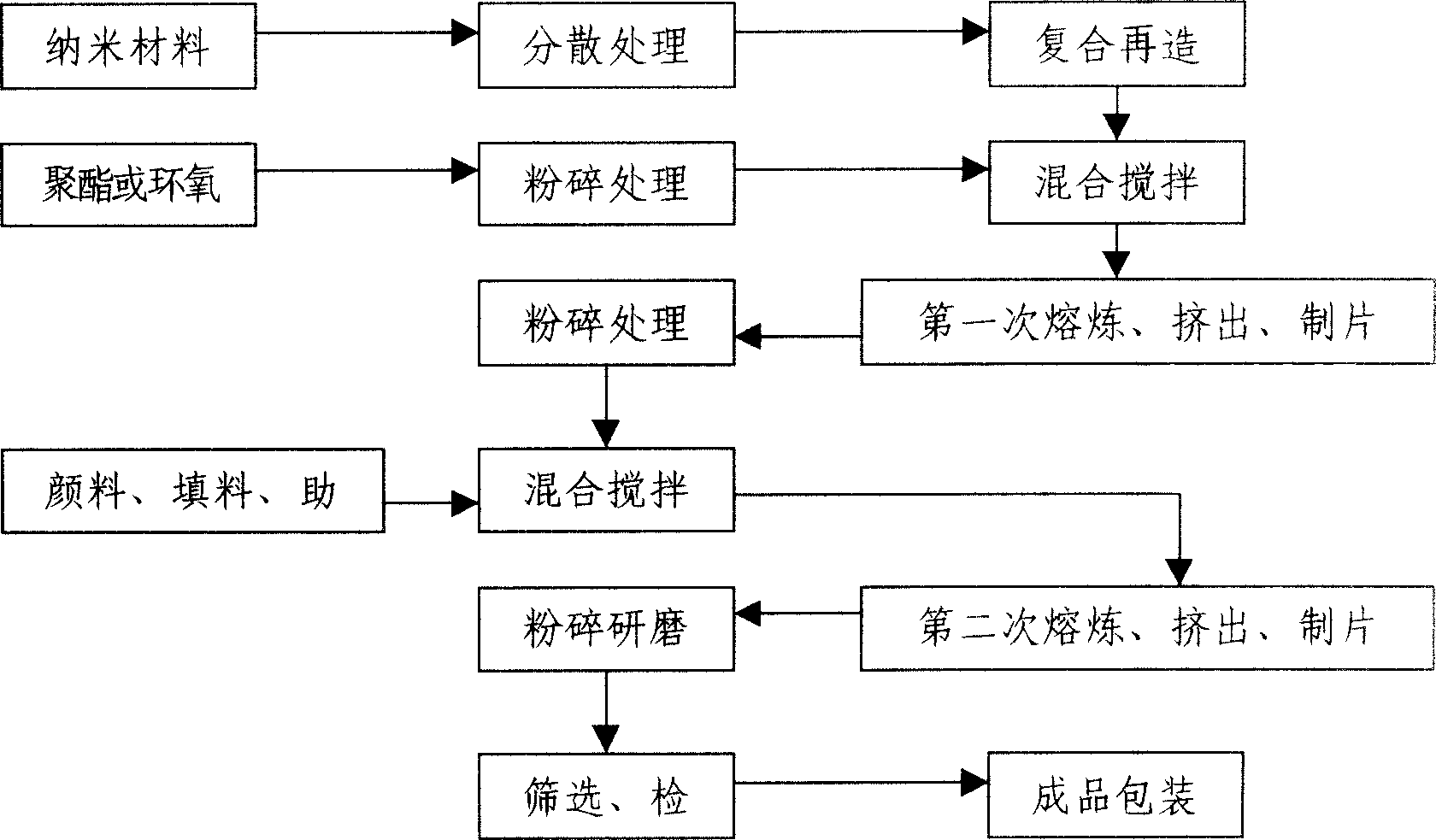

Method used

Image

Examples

Embodiment Construction

[0043] 1. Design requirements for particle size and particle size ratio of micron materials and nanomaterials

[0044] (1) Particle size requirements of micron powder coating materials

[0045] ①The particle size of polyester or epoxy resin material is within 0.5μm~50μm;

[0046] ② The particle size of other pigments, fillers and additives should be above 35μm.

[0047] (2) Requirements for particle size of nanomaterials

[0048] The magnitude of the inorganic nanoparticles is within the range of 5 nm to 100 nm.

[0049] (3) Requirements for the particle size ratio of inorganic composite nanomaterials to the particle size of micron materials

[0050] The ratio of the diameter of the inorganic composite nanometer particles after regranulation to the particle diameter of the polyester or epoxy resin particles is within (0.1-100):(100-100000).

[0051] 2. Technical requirements for inorganic composite nanomaterials

[0052] Nanoparticles of various materials in the inorganic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com