Chemical battery with porous indium phosphide, electrochemical corrosive system and method

An electrochemical and indium phosphide technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems that no one has proposed the design of electrochemical cells, and no one has proposed the preparation process of semiconductor materials such as corrosion of porous indium phosphide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order that the present invention can be more fully understood, it will be illustrated below in conjunction with reference to the accompanying drawings, wherein, figure 1 Schematic illustration of the shape of the auxiliary platinum electrode, where the material used is platinum (99.95%);

[0041] figure 2 The shape of the indium phosphide back electrode is schematically given, where the material used is gold (99.95%):

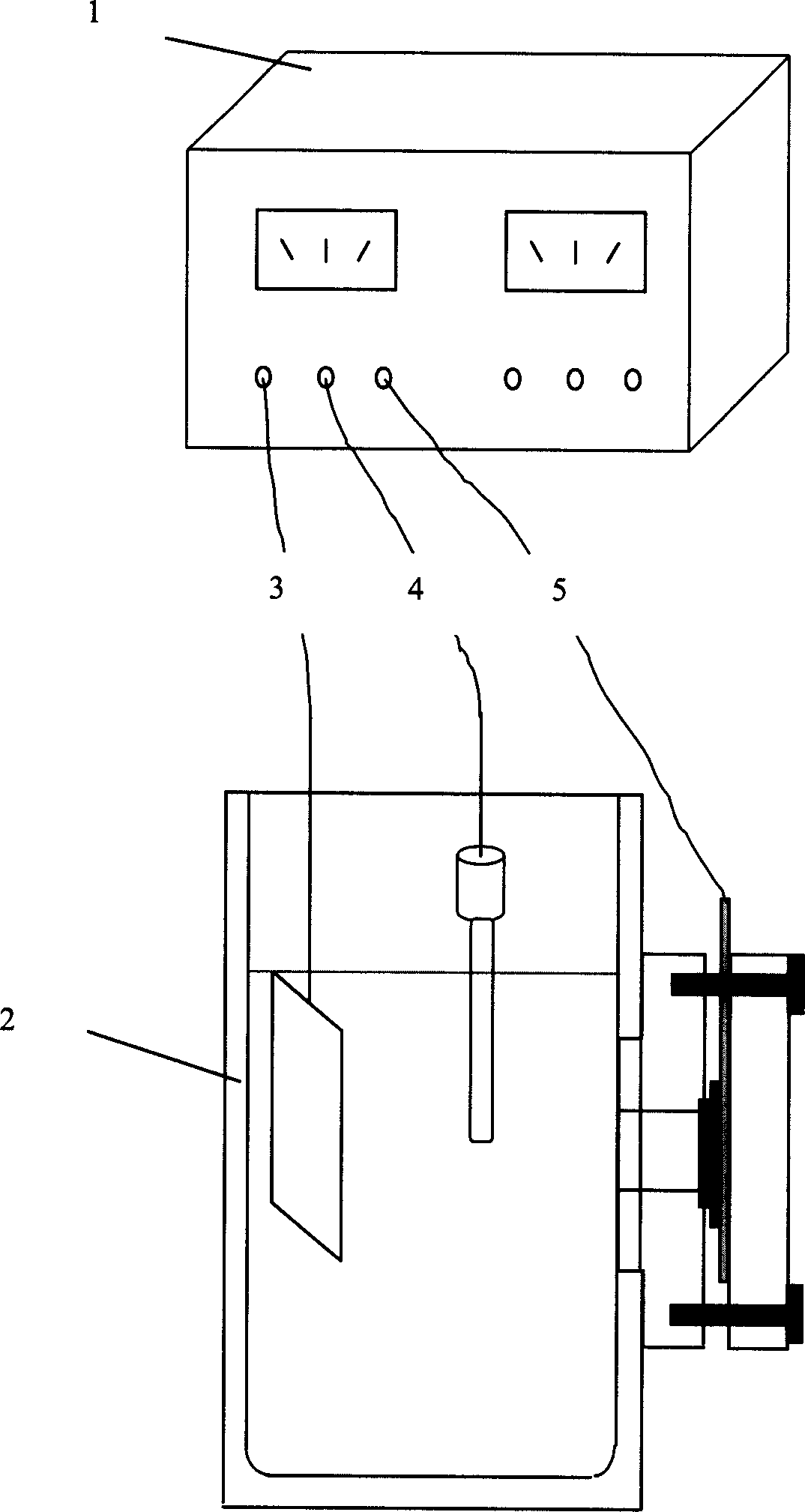

[0042] image 3For the equipment and corrosion system needed by the present invention, it comprises a potentiostatic galvanostat 1, electrochemical cell 2, the electrochemical system of three electrodes (comprising platinum auxiliary electrode 3, saturated calomel reference electrode 4, and phosphating Indium working electrode 5);

[0043] Figure 4 Be the electrochemical cell designed in the present invention; Fig. 5 is the installation process of this electrochemical cell;

[0044] As an example of the present invention, the following combinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com