Slow releasing urea and its producing method

A technology of slow-release urea and its production method, which is applied in the direction of urea compound fertilizer, nitrogen fertilizer, fertilizer mixture, etc., and can solve the problems of not being used on a large scale, not matching the peak period of nitrogen absorption, and slow-release too fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

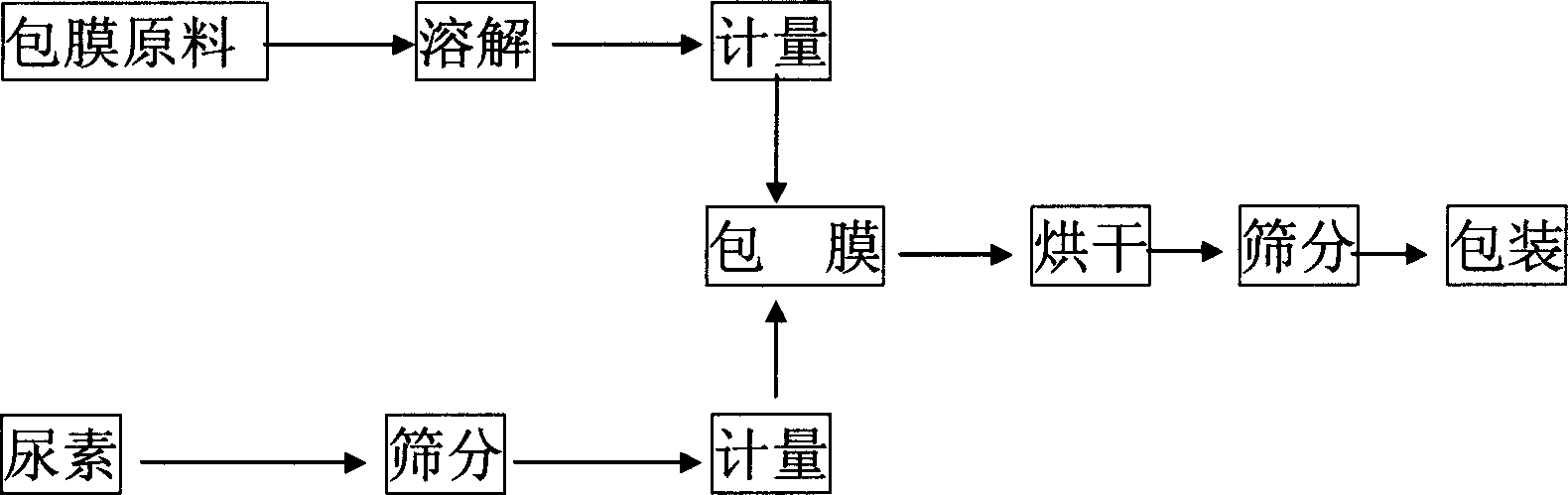

Method used

Image

Examples

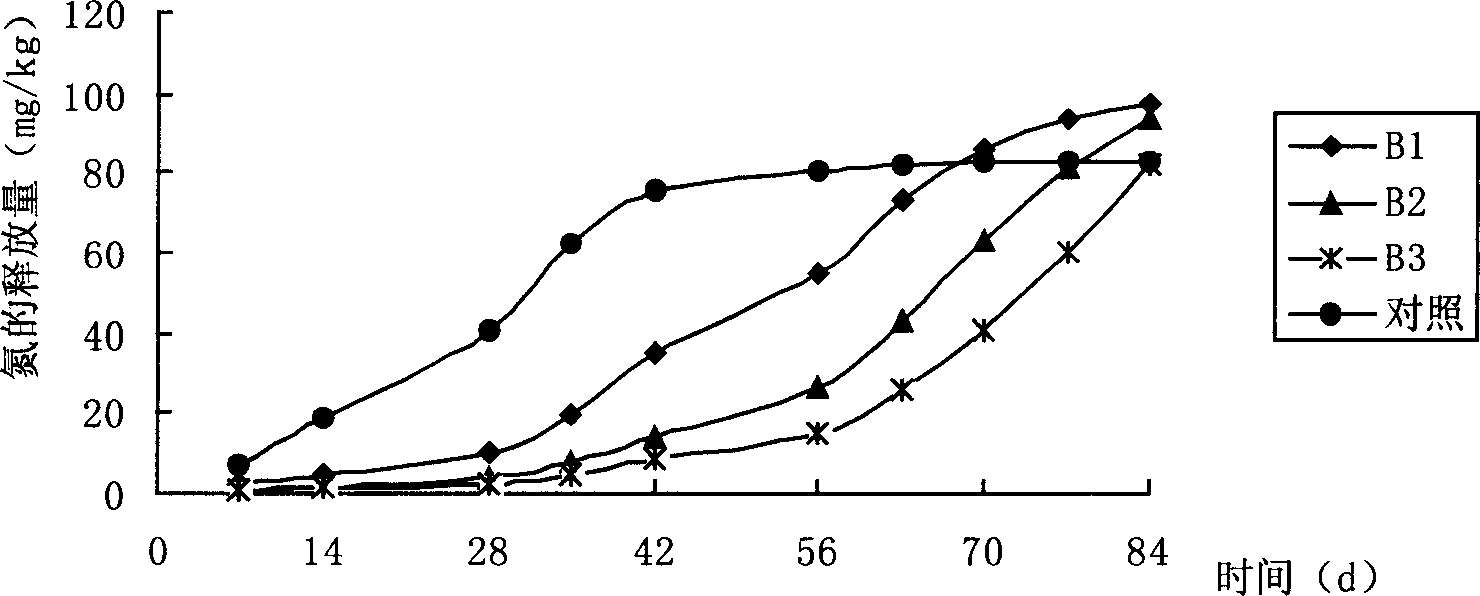

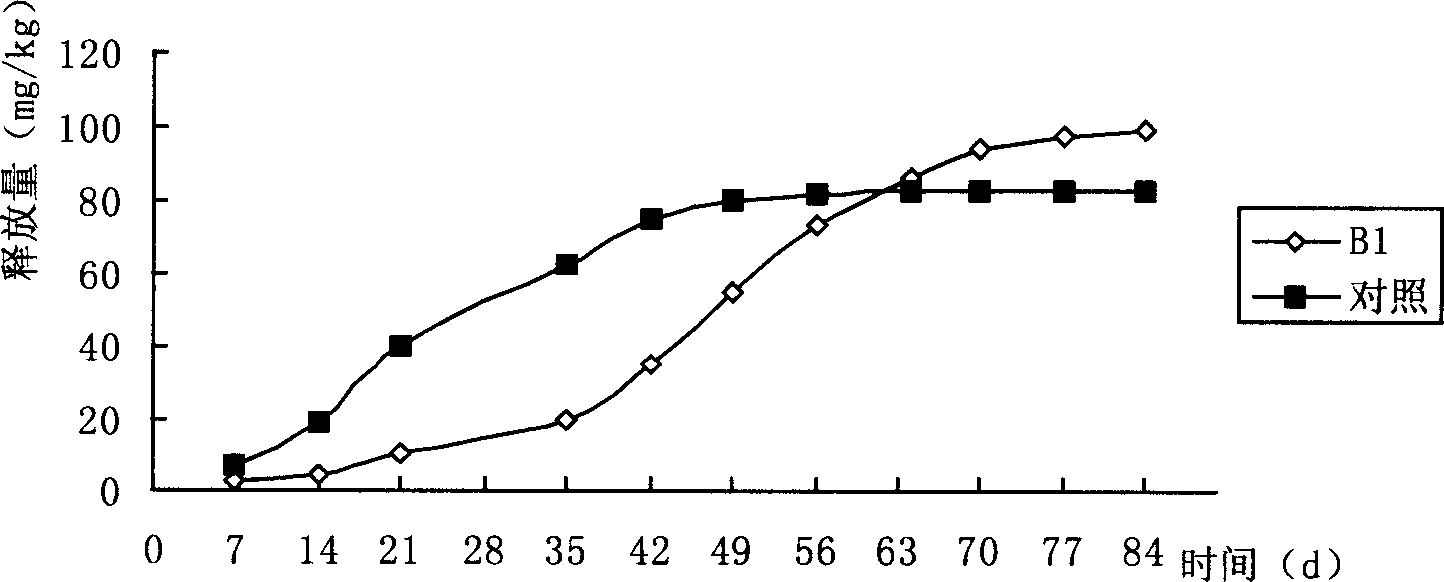

Embodiment 1

[0100] Sieve the qualified product granular urea produced by Daqing Petrochemical General Plant into the particle size of φ2.00~3.00mm, and leave 10kg after measuring with a platform scale; take 0.1kg of analytically pure polyvinyl acetate produced by Zhangjiang Fine Chemical Factory of Shanghai Sanwei Pharmaceutical Company, 0.4 kg of analytically pure methanol produced by Beijing Chemical Plant, adding polyvinyl acetate to methanol while stirring and heating to dissolve, the dissolution temperature is 120 ° C, measured with a platform scale after all the dissolution, and replenishing the volatilized methanol to the amount before volatilization is obtained Coating solution.

[0101] Put the above-mentioned granular urea in the coating pan, set the rotating speed of the coating pan to 200 rpm, and set the coating temperature to 60°C; at the same time, spray the above-mentioned coating solution to the granular urea in the coating pan intermittently with a spray gun. The gas pre...

Embodiment 2

[0103] Sieve the qualified product granular urea produced by Daqing Petrochemical General Plant into the particle size of φ2.00~3.00mm, and leave 10kg after measuring with a platform scale; take 0.31kg of analytically pure polyvinyl acetate produced by Zhangjiang Fine Chemical Factory of Shanghai Sanwei Pharmaceutical Company, 1.24kg of analytically pure methanol produced by Beijing Chemical Plant, adding polyvinyl acetate to methanol while stirring and heating to dissolve, the dissolution temperature is 150°C, measured with a platform scale after all the dissolution, and replenishing the volatilized methanol to the amount before volatilization is obtained Coating solution.

[0104] Put the above-mentioned granular urea in the coating pot, the speed of the coating pot is set to 200 rpm, and the coating temperature is set to 70°C; at the same time, the above-mentioned coating solution is intermittently sprayed on the granular urea in the coating pot with a spray gun. The gas pr...

Embodiment 3

[0106] Sieve the qualified product granular urea produced by Daqing Petrochemical General Plant into the particle size of φ2.00~3.00mm, and leave 10kg after measuring with a platform scale; take 0.2041kg of analytically pure polyvinyl acetate produced by Zhangjiang Fine Chemical Factory of Shanghai Sanwei Pharmaceutical Company, 0.8164kg of analytically pure methanol produced by Beijing Chemical Plant, adding polyvinyl acetate to methanol while stirring and heating to dissolve, the dissolution temperature is 135°C, measured with a platform scale after all the dissolution, and replenishing the volatilized methanol to the amount before volatilization is obtained Coating solution.

[0107] Put the above-mentioned granular urea in the coating pan, set the rotating speed of the coating pan to 200 rpm, and set the coating temperature to 65°C; at the same time, spray the above-mentioned coating solution to the granular urea in the coating pan intermittently with a spray gun. The gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com