Particulate titanium oxide, method and apparatus for manufacturing the same, and treatment methods using such titanium oxide

A manufacturing method and technology for manufacturing devices, applied in the field of titanium oxide particles and their manufacturing, manufacturing devices, and treatment using the titanium oxide, capable of solving problems such as reduced photocatalytic activity and reduced surface area, achieving high decomposition efficiency and high bactericidal effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0175] A synthesis tube made of quartz glass is used, and the heat source is an oxyhydrogen flame lamp. Titanium tetrachloride vapor and oxygen are introduced into the synthesis tube, and titanium oxide particles are produced by a thermal oxidation method heated from the outside of the synthesis tube. Titanium tetrachloride vapor was supplied by bubbling, the temperature of the bubbler was set to 85°C, and the pipe insulation temperature was set to 140°C. Argon was used as the bubbling gas, and its flow rate was set to 180 sccm. The reaction oxygen flow rate was set at 1000 sccm, and the synthesis temperature was set at 1230°C. Equipped with 6 oxyhydrogen flame lamps. The inner diameter of the quartz glass tube was 32 mm and the thickness was 2.5 mm, and it was rotated at 55 rpm.

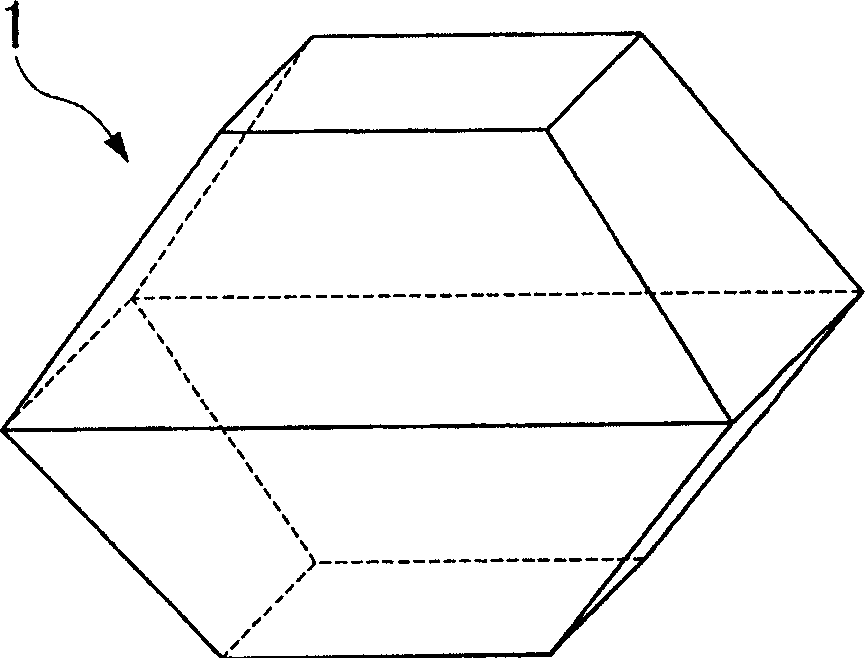

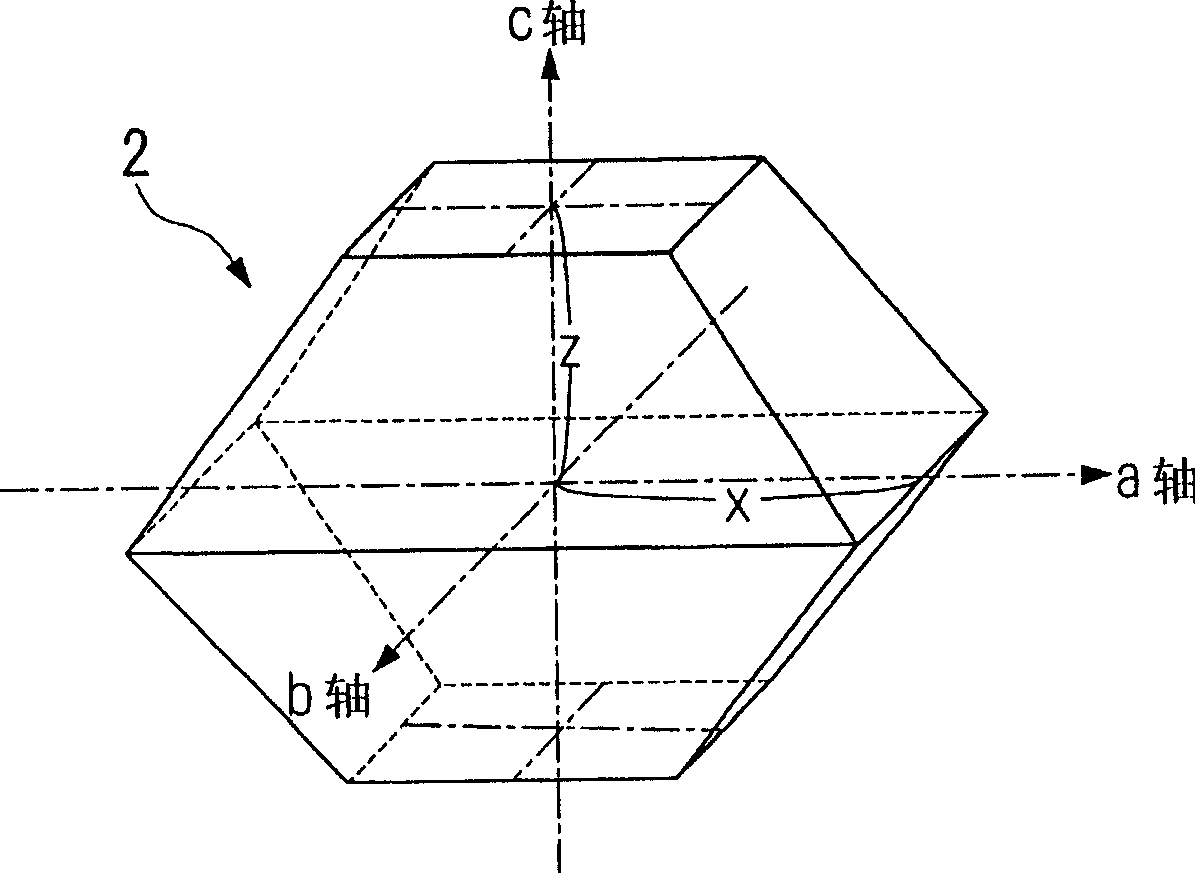

[0176] The shape of the obtained titanium oxide particles was as follows figure 1 The decahedron shown. The average particle diameter is 20 nm, and the particle diameter distribution is such tha...

Embodiment 2

[0183] The titanium oxide particles obtained in Example 1 were coated on a quartz glass plate, and the photocatalytic activity was evaluated by ultraviolet irradiation.

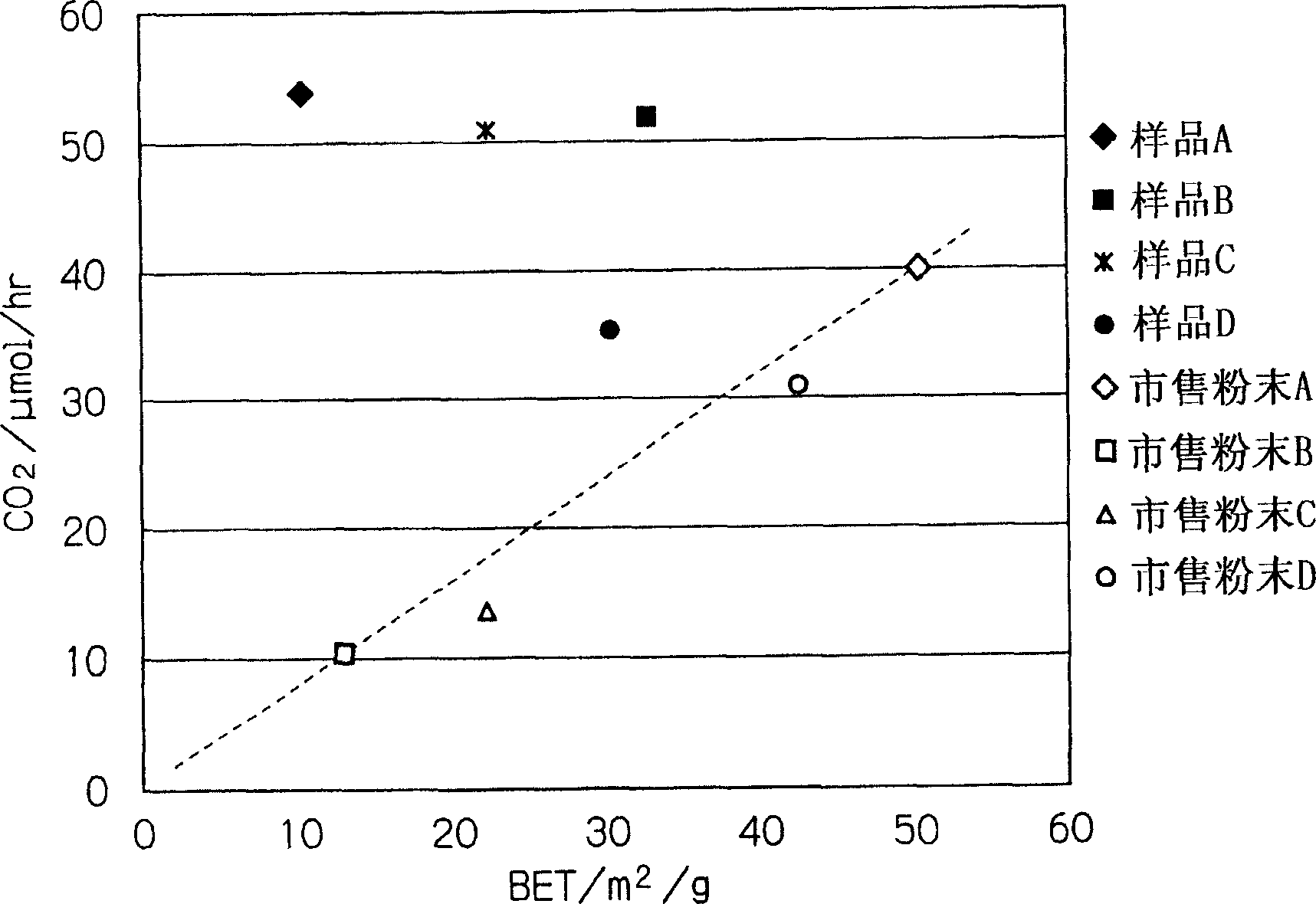

[0184] The evaluation was performed using the ability to decompose acetaldehyde under the same conditions, and the concentration of carbon dioxide generated after decomposition was measured to compare the relationship with the oblateness H of the polyhedron constituting the titanium oxide particles. exist Figure 9 The middle represents the change with time of the carbon dioxide concentration of the titanium oxide catalyst having each oblateness. As a result, the samples with the flatness ratios of the polyhedrons of 1.01 and 1.58 showed the highest activity, and the samples with the flatness ratios of 0.53 and 2.16 showed slightly lower activities.

Embodiment 3

[0188] The titanium oxide particles obtained in Example 1 were coated on a quartz glass plate, coated with Escherichia coli, and irradiated with an ultraviolet lamp to investigate changes in the number of Escherichia coli over time. % or less of the time is 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com