High activaty 24 photocatalyst Caln2O4 and its preparation process

A photocatalyst, cain2o4 technology, applied in the field of photocatalytic materials and preparation, can solve the problems of uneven distribution of components, affecting performance, time-consuming and energy consumption, etc., and achieve the effect of low sample synthesis temperature, low product impurity content and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Weigh 2.362 grams of Ca(NO 3 ) 2 4H 2 O, 7.638 grams 3.336 g organic fuel C 2 h 5 NO 2 , after putting into the container, add 50ml of deionized water, stir for 30 minutes to make it fully mixed;

[0023] (2) Take about 20 ml of the solution and place it in a 100 ml container, and cover the mouth of the container with two layers of wire mesh to prevent the material from splashing out during combustion. Keep the container at 200°C for 30 minutes;

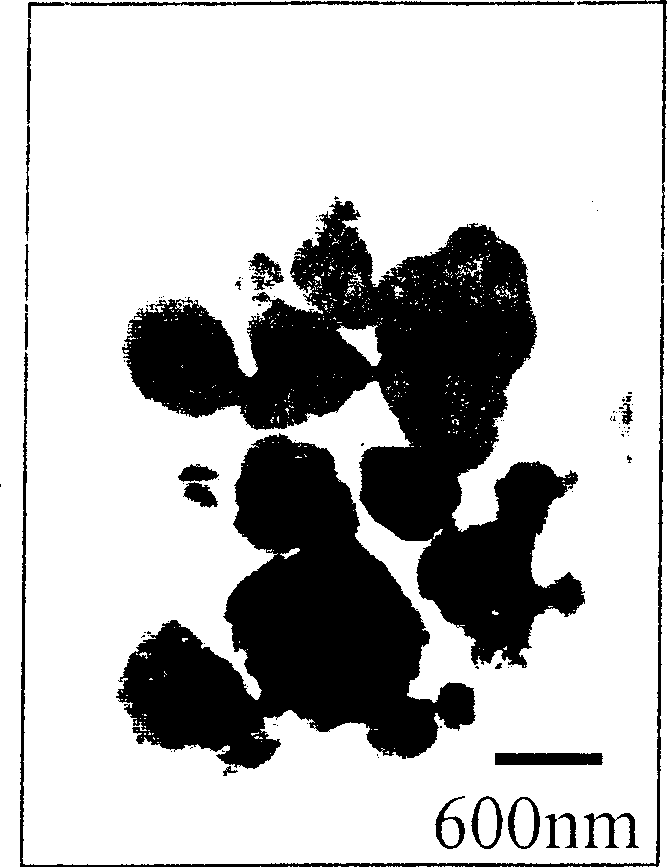

[0024] (3) Then slowly heat up to 300°C at a rate of 3°C / min to fully burn the solution in the container to obtain fluffy CaIn 2 o 4 Powder. figure 1 It is an electron micrograph of the powder. It can be clearly seen from the figure that the powder is a nano-rod structure, and its length dimension is about 2 to 5 times that of the radial dimension.

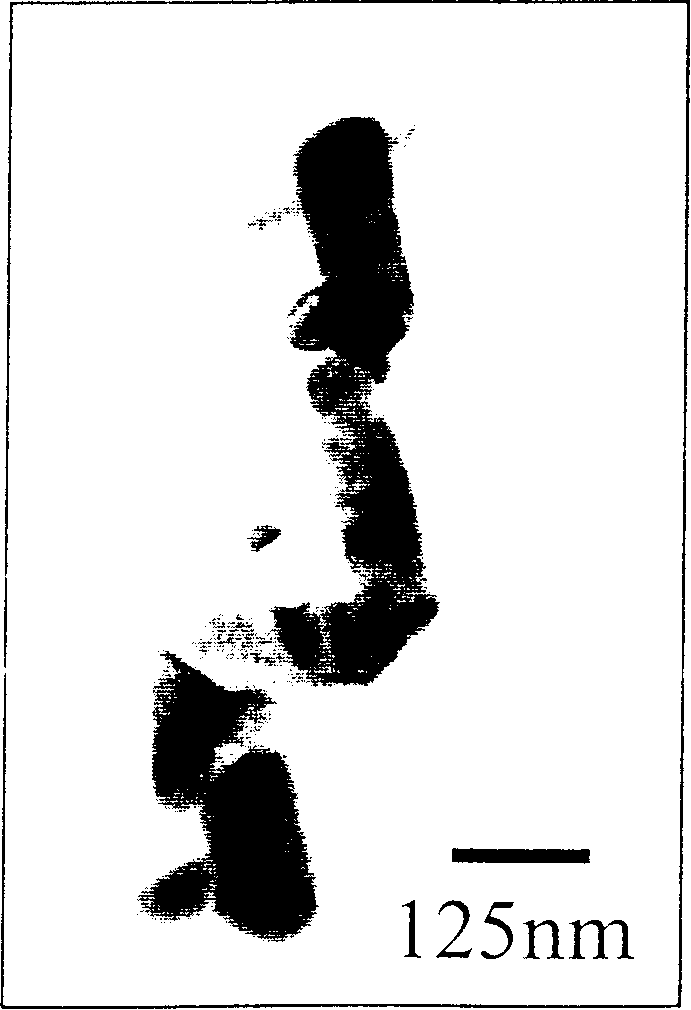

[0025] (4) The above-mentioned combustion powder is baked at 1100° C. for 12 hours. figure 2 It is an electron microscope photo of the powder. It can be clearly s...

Embodiment 2

[0029] (1) Weigh 3.308 grams of Ca(NO 3 ) 2 4H 2 O, 10.693 grams 4.670 g C 2 h 5 NO 2 , add 70 ml of deionized water to make a solution, stir for 20 minutes to make it evenly mixed;

[0030] (2) Take 30 ml of the solution and place it in a 100 ml container, cover the mouth of the container with two layers of wire mesh, and keep the container at 250°C for 20 minutes at a constant temperature;

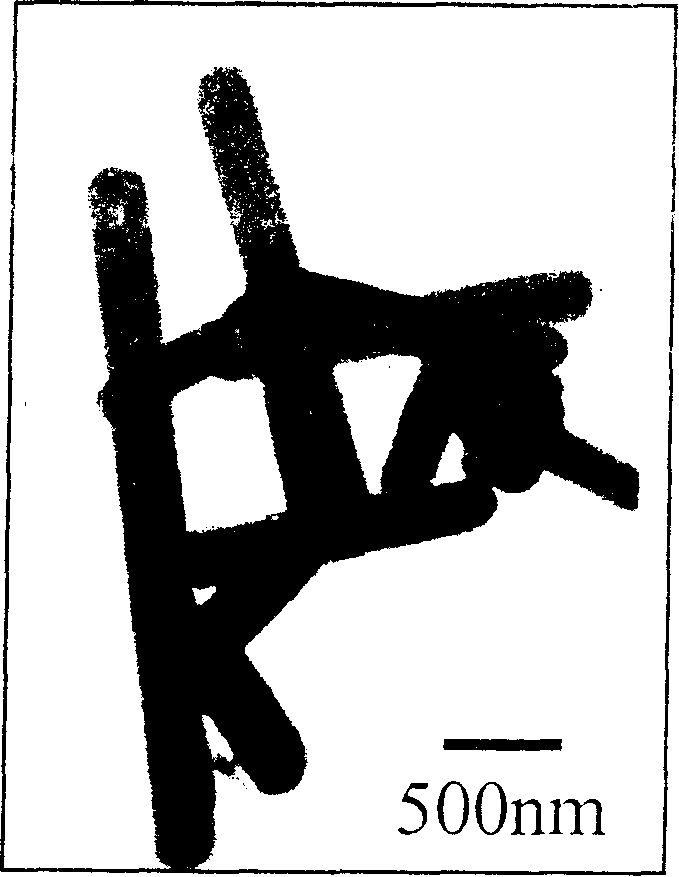

[0031] (3) Then slowly heat up to 300°C at 2°C / min to fully burn the solution in the container to obtain fluffy CaIn 2 o 4 Powder, the powder was fired at 1200°C for 8 hours to obtain a long and thin rod-shaped structure of CaIn 2 o 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com