Method of producing dimethyl carbonate

A technology of dimethyl carbonate and methyl nitrite, which is applied in the field of synthesizing dimethyl carbonate by methanol oxidative carbonylation, can solve the problems of prolonging the service life of the catalyst and insufficient stability of the catalyst activity, and achieve long life and reduced hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

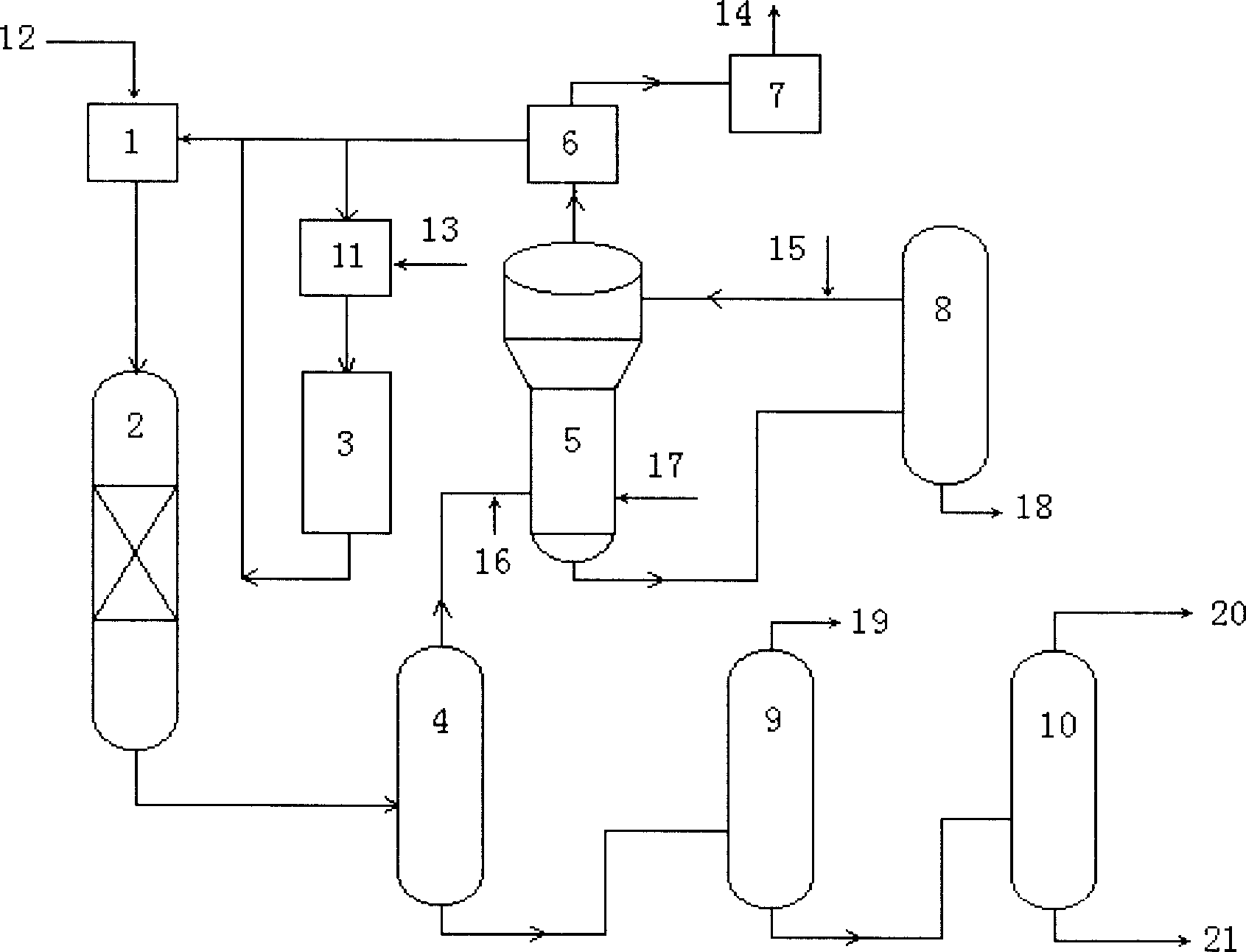

Image

Examples

Embodiment 1

[0023] 100ml PdCl in the main reaction area 2 ~CuCl 2 ~AlCl 3 / AC catalyst, the inner diameter of the reaction zone is 30mm, and the length is 600mm. The upper and lower parts of the catalyst bed are respectively equipped with the same amount of inert fillers with the same particle size as the catalyst to ensure the preheating and uniform distribution of the reaction raw material gas.

[0024] 1ml PdCl in the auxiliary reaction zone 2 / γ~Al 2 o 3Catalyst, the inner diameter of the reaction zone is 5 mm, and the length is 100 mm. The upper and lower layers of the catalyst bed are equipped with the same amount of inert fillers with the same particle size as the catalyst to ensure the preheating and uniform distribution of the reaction raw material gas.

[0025] The composition (V) of the raw material entering the auxiliary reaction zone is CO10%, CH 3 ONO2%, HCl1%, the rest is inert gas and a small amount of NO, CH 3 OH et al. The total flow is 5l.h -1 , that is, the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com