Isosorbide mononitrate capsule and dry preparation method

A preparation technology of isosorbide dinitrate, which is applied in the field of medicine, can solve the problems of sublimation loss, slow disintegration, and rapid onset of uncomfortable drugs, etc., and achieve the effect of simple process and improved product output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

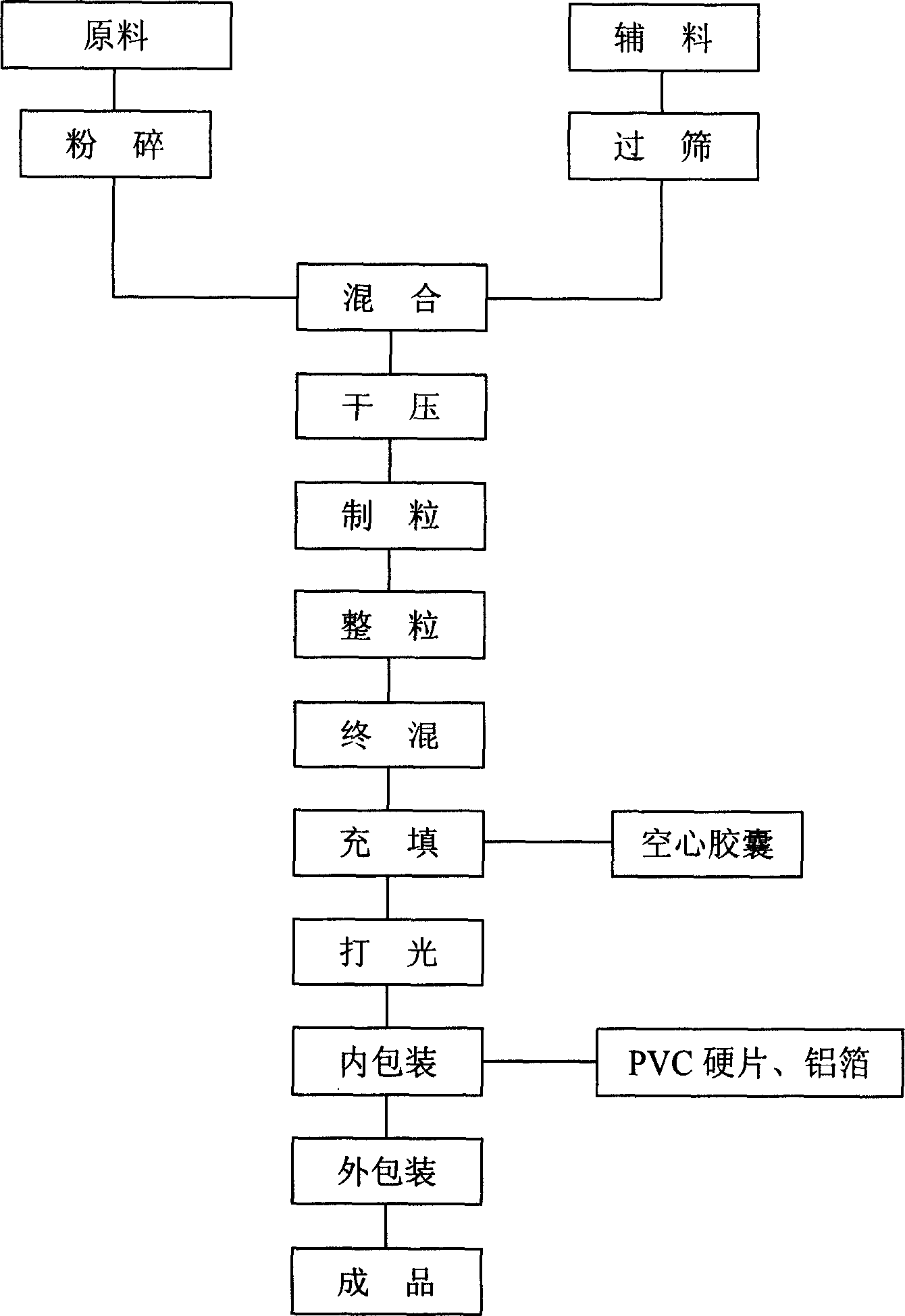

[0015] The present invention will be further described below in conjunction with accompanying drawing:

[0016] Calculated on the basis of 1,000,000 capsules:

[0017] Isosorbide mononitrate 20kg

[0018] Filler 221kg

[0019] Carboxymethyl starch sodium 5kg

[0020] Magnesium stearate 0.5kg

[0021] Fillers include: calcium hydrogen phosphate 70kg, microcrystalline cellulose 75kg, lactose 76kg

[0022] The disintegrant is sodium carboxymethyl starch, the lubricant is magnesium stearate

[0023] With reference to accompanying drawing, according to this process, at first 70kg of calcium hydrogen phosphate, 75kg of microcrystalline cellulose, 76kg of lactose are used as fillers, 20kg of isosorbide mononitrate, and 5kg of disintegrating agent are uniformly mixed by a fluidized bed one-step granulator, and then mixed with Dry press granulation and pass through a 24-mesh sieve, add 0.5kg of lubricant and mix evenly in a mixer, me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com