Method for extracting and separating silver linden glycoside from oriental paperbush flower

A technology for tiliacoside and fragrant flower, which is applied in the field of extraction and separation of tiliacoside, and achieves the effects of high yield, low cost and high product content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

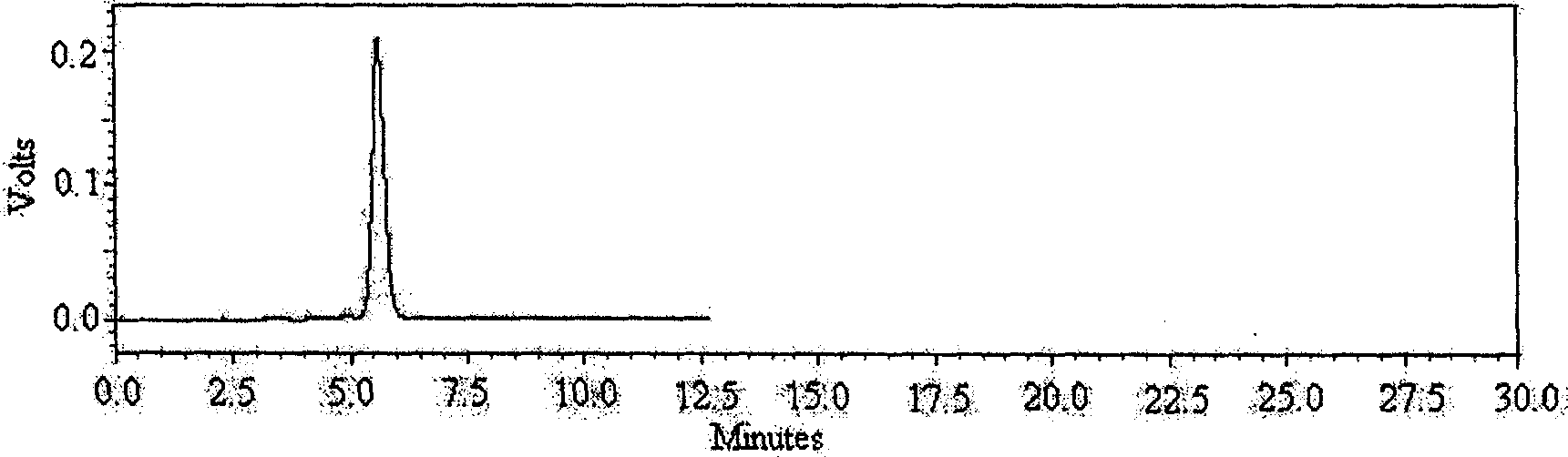

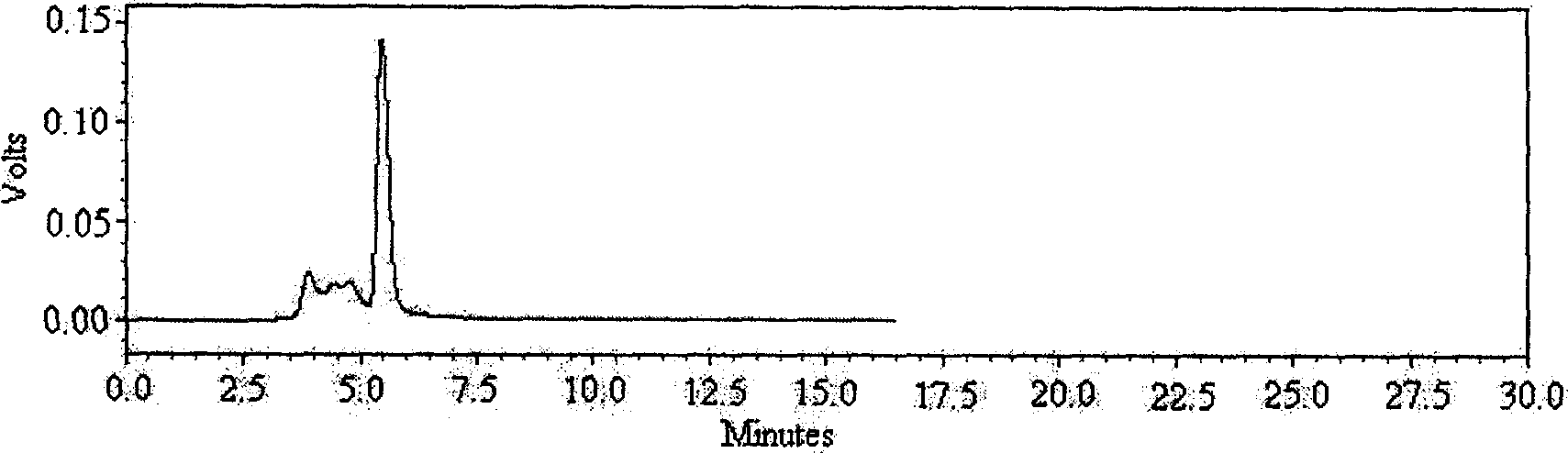

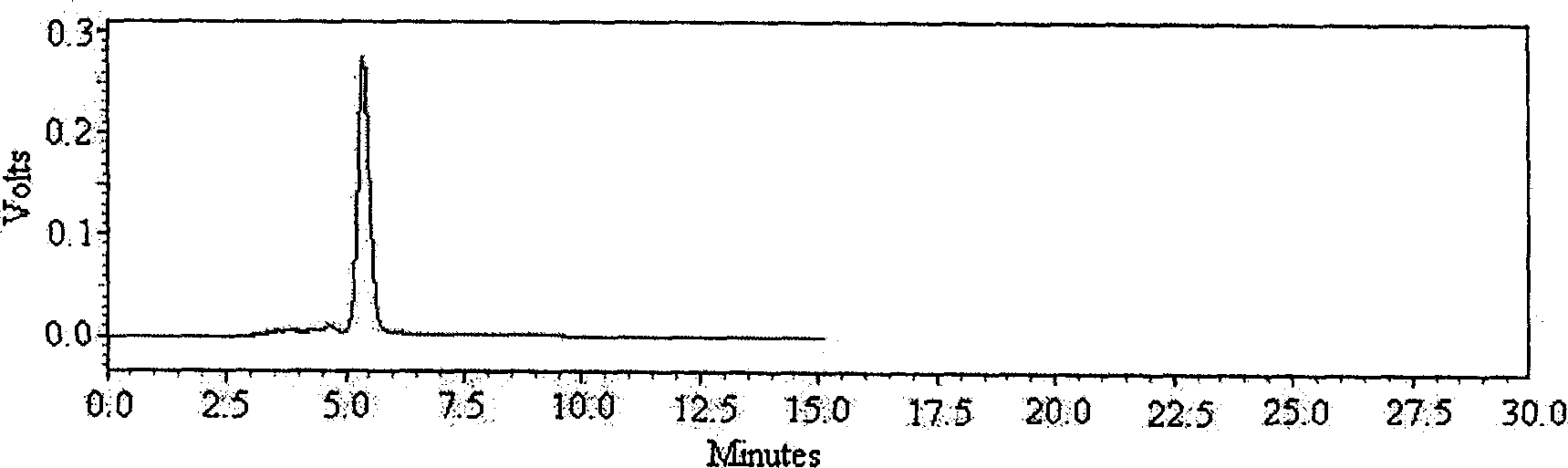

[0026] (1) Get 100.0g of jiexianghua, use 10 times the amount of 95% industrial ethanol to reflux extract for 1.5h, filter, and filter the residue to continue to use 8 times the amount of 95% industrial ethanol to reflux extract for 1h, filter, combine the filtrates, reclaim the ethanol to dryness, and obtain Concentrate 9.6 g. For liquid chromatography of the concentrate see figure 2 (Chromatographic conditions: the chromatographic column is Shim-Pack CLC ODS(M)C 18 (4.6mm×250mm, 5μm); mobile phase: methanol-water (7:3, V / V); flow rate: 0.8ml / min; detection wavelength: 254nm. figure 1 , 2 , 3, 4, 5 chromatographic conditions are the same).

[0027] (2) Add 100ml of water to the concentrate, stir thoroughly for half an hour at room temperature, filter, and wash the filter cake with a small amount of water for several times until the washing liquid is colorless. The filter cake was dried to obtain 2.180 g, with a content of 58.1%. For liquid chromatography of water washes...

Embodiment 2

[0030] (1) Take 500.0g Jiexianghua, use 3800ml of 78% industrial ethanol, extract at room temperature for 4 days, filter, continue to extract the filter residue with 3000ml of 78% industrial ethanol for 3 days at room temperature, filter, combine the filtrates, recycle the solvent, and obtain 50.0g concentrated things.

[0031] (2) Take 10.0g of the concentrate, add 130ml of water, put it in a water bath at 60°C, fully stir for about 30 minutes, filter, wash the filter cake with a small amount of water, and obtain 2.634g of water washings, which are directly used in the next step without drying. step. Add 25ml of chloroform to the water washings, reflux extraction for about 30min, filter, and wash with a small amount of chloroform for several times until the washing liquid is colorless, and the filter cake is dried to obtain 1.002g with a content of 91.3%.

[0032] (3) Add 70ml of 95% industrial ethanol to the chloroform extract, heat up to reflux, stir to dissolve, filter, a...

Embodiment 3

[0034] (1) With embodiment 2 step (1).

[0035] (2) Take 8.5g of the concentrate, add 60ml of water, fully stir for 30min at room temperature, filter, wash the filter cake with a small amount of water several times, and dry to obtain 1.859g. Add 22ml of dichloromethane to the washings, reflux for extraction for about 30 minutes, filter, and wash with a small amount of dichloromethane for several times until the washing liquid is colorless, and the wet weight of the filter cake is 1.023g.

[0036](3) Add 25ml of methanol to the dichloromethane raffinate, heat up to reflux, stir to dissolve, filter, concentrate the filtrate to 10ml, add 10ml of water, stand still for several hours, filter, and dry to obtain 0.695g silver tidalin, the content is 97.7% . The content of silver lintin in A. japonica is calculated as 1.56%, and the total extraction rate of silver lintin is 51.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com