Method for preparing formulation containing Indianmulberry extract

A technology of Morinda officinalis oligosaccharides and excipients, which is applied to medical preparations containing active ingredients, drug combinations, pill delivery, etc., can solve the problems of prolonged production cycle, large amount of excipients, and increased product costs, and achieve The effect of increasing the content rate, reducing product cost, and reducing the amount of auxiliary materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

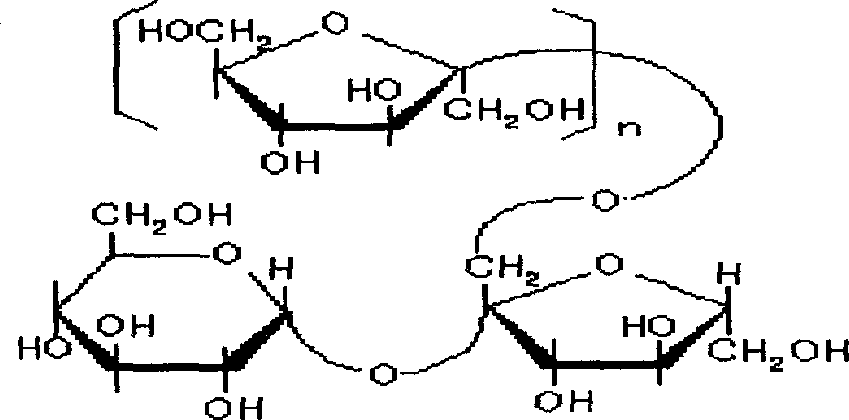

Image

Examples

Embodiment 1

[0018] Example 1: Preparation of Morinda officinalis oligosaccharide granules formed at one time

[0019] In the GPCG1 fluidized bed, put 500 g of PH102 microcrystalline cellulose powder with a particle diameter of 0.20 mm (equivalent to passing through an 80-mesh sieve) into the fluidized bed, and set the following key parameters: inlet air temperature 40-45 °C , the air inlet pressure is 0.35bar~0.45bar, the atomization pressure is 1.5bar~2.0bar, and the spray rate is 15rpm~25rpm. Other parameters are fixed at: filter bag shaking frequency 6 times / min, shaking time 5 seconds / time, nozzle diameter 1.0mm, fluidization air volume before granulation 0.30bar, fluidization time 2-5 minutes. Concentrate the water extract medicinal solution obtained from Morinda officinalis as a raw material into 1000g of liquid extract with a specific gravity of 1.12-1.15, and spray it into the fluidized bed in the form of mist and bottom spray. The spray rate of the liquid medicine is carried out...

Embodiment 2

[0020] Example 2: Preparation of Morinda officinalis Oligosaccharide Capsules of 150mg Specification

[0021] The Morinda officinalis oligosaccharide granules prepared in Example 1 were filled into No. 2 ordinary hollow capsules according to the weight of 225 mg, and sealed with blisters of PVC hard sheets and aluminum foil, and the packaging specification was 12 capsules / board. Each capsule contains Morinda officinalis oligosaccharides 150mg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com