Gallium nitride based LED chip and its manufacturing method

A light-emitting diode, gallium nitride-based technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of increasing chip temperature, affecting the reliability and life of the chip, and improving the working current and input power. , The effect of improving the current diffusion and improving the heat dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further illustrate the content of the present invention, the present invention will be described in detail below in conjunction with the examples.

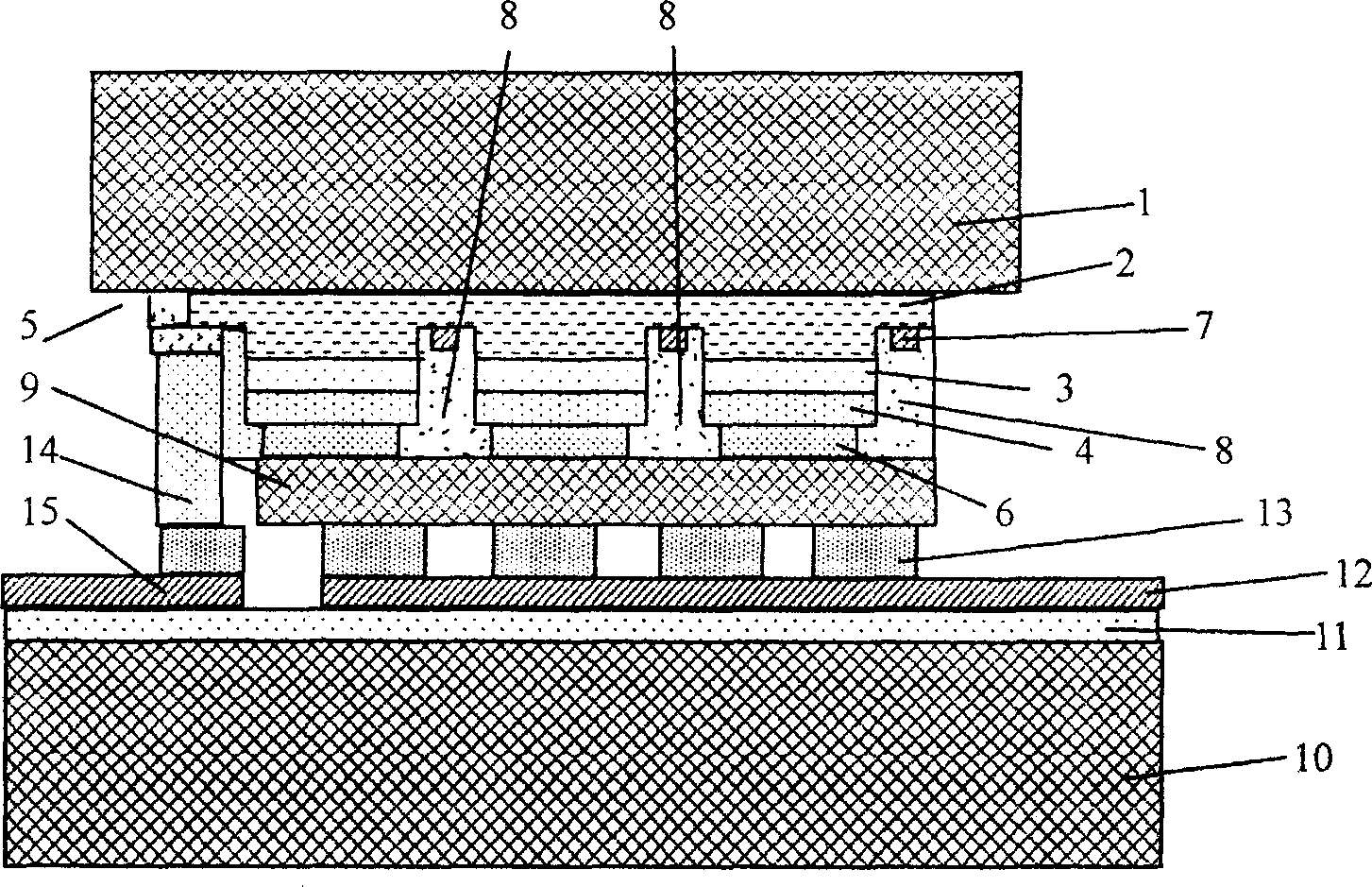

[0023] refer to image 3 , in the gallium nitride-based light-emitting diode chip shown, a sapphire substrate 1 with a thickness between 70 microns and 150 microns (such a thickness has both good light transmission and relatively good manufacturability) is set There is an N-type contact layer 2, and stacked light-emitting active regions 3, P-type contact layers 4 and P-type contact electrodes 6 are discretely arrayed on the N-type contact layer 2, and each group of light-emitting active regions 3, P-type The contact layer 4 and the P-type contact electrode 6 form an array unit, and the N-type contact electrode 7 of grid structure encloses each array unit in a grid. General array element linearity (circular linearity refers to the length of diameter, ellipse linearity refers to the length of long diameter, trian...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com