Proton exchange membrane of direct alcohol fuel cell and method for preparing membrane electrode

A fuel cell and alcohol barrier membrane technology, which is applied to fuel cell parts, fuel cells, battery electrodes, etc., can solve the problems of poor electrode performance, weak bonding between alcohol barrier membrane and electrolyte membrane, peeling, etc., so as to improve electrode performance. , The effect of preventing fuel permeation and methanol permeation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] 2. Preparation of the alcohol barrier film: take the treated Nafion film and plate a palladium (Pd) film with a thickness of 0.05-50 on its surface by means of electroless plating.

[0049] 3. Treatment of Pd / Nafion composite membrane: use 0.5M H for the Pd / Nafion composite membrane 2 SO 4 The solution is treated at a temperature of 40-100° C. for 2-12 hours, and then treated with deionized water for 2-12 hours (twice). Treat with 0.5M NaOH for 2 to 12 hours, and then treat with deionized water for 2 to 12 hours (twice).

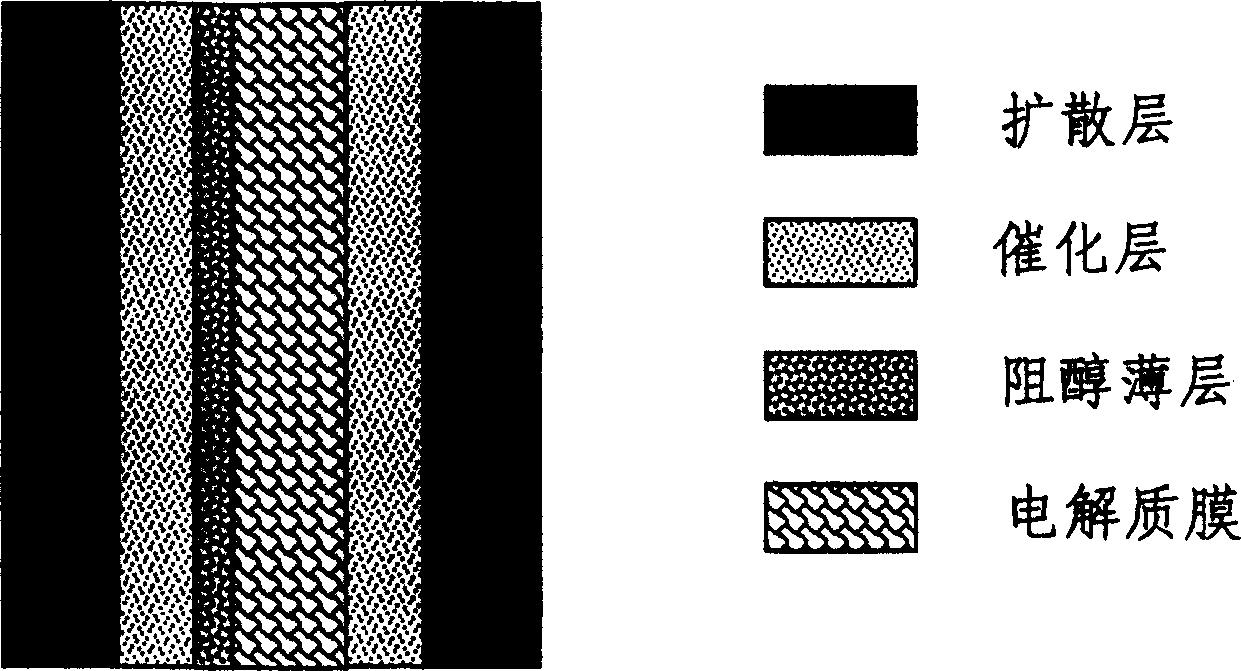

[0050] 4. Catalyst layer preparation: The cathode and anode catalyst layers are respectively covered on both sides of the Pd / Nafion composite membrane by direct spraying or pressure transfer method. The position of the alcohol barrier palladium (Pd) membrane can be placed on the cathode side or the anode side according to specific requirements, or pressed between two Nafion electrolyte membranes

[0051] 5. Activation of the multilayer film electro...

Embodiment 1

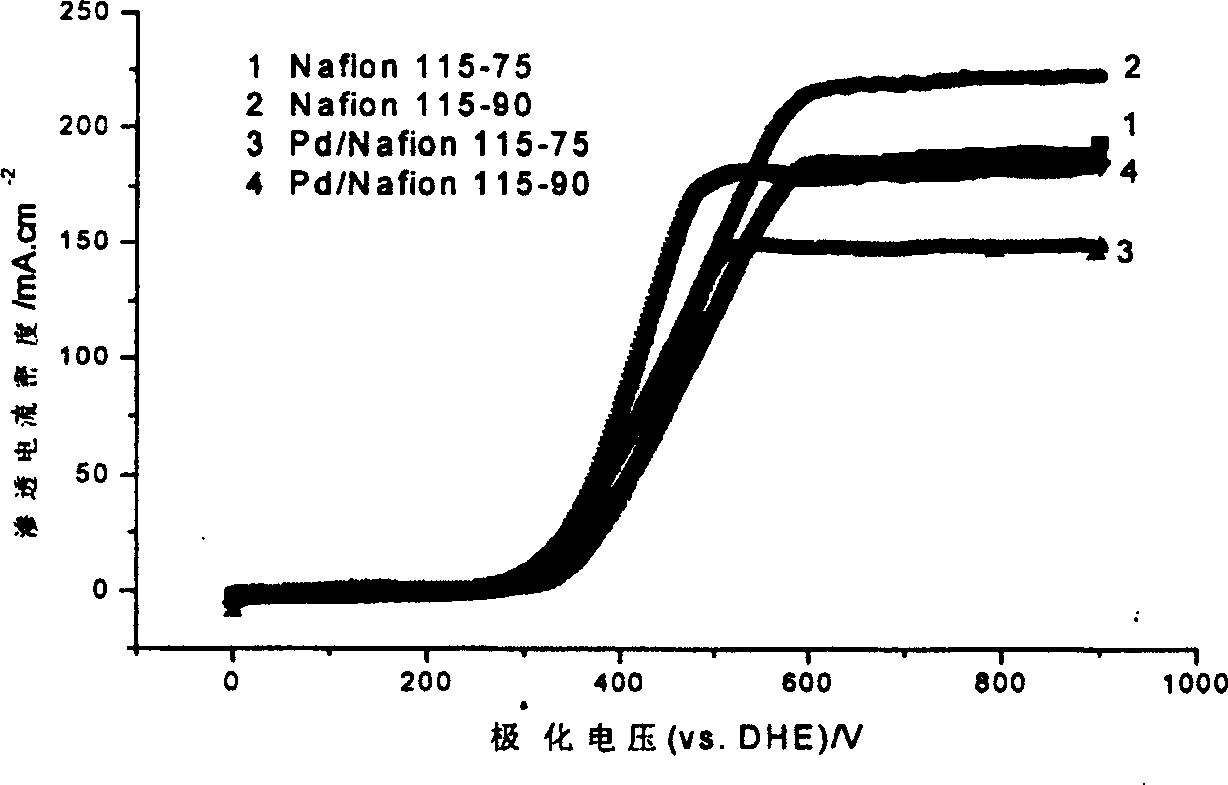

[0053] Configure 1N PdCl 2 solution, 10 mL of 1N HCl solution was added. The processed 4×4cm 2 The Nafion 115 membrane was soaked in the prepared solution, kept at 30°C for 5 minutes, taken out and rinsed with deionized water, then placed in 1N hydrazine solution for 6 minutes, and repeated 5 times to treat the membrane. Immerse the activated and sensitized Nafion 115 membrane into the plating solution, the composition of the plating solution is: PdCl 2 6g / L, EDTA 67g / L, NH 3 ·H 2 O 350mL / L, N 2 NNH 2 , 0.5ml / L, surfactant: 1% volume, + sodium ethanesulfonate. The plating solution was stirred with a magnetic stirring bar, and a Pd film was chemically deposited on one side of the Nafion 115 film under the condition of 30°C, and the thickness of the Pd film was about 5 μm. The Pt / Ru black and Pt black catalysts were directly sprayed on both sides of the Pd / Nafion 115 membrane respectively. 2 , Nafion content is 15wt.%. The cathode catalyst is a Pt black catalyst with a...

Embodiment 2

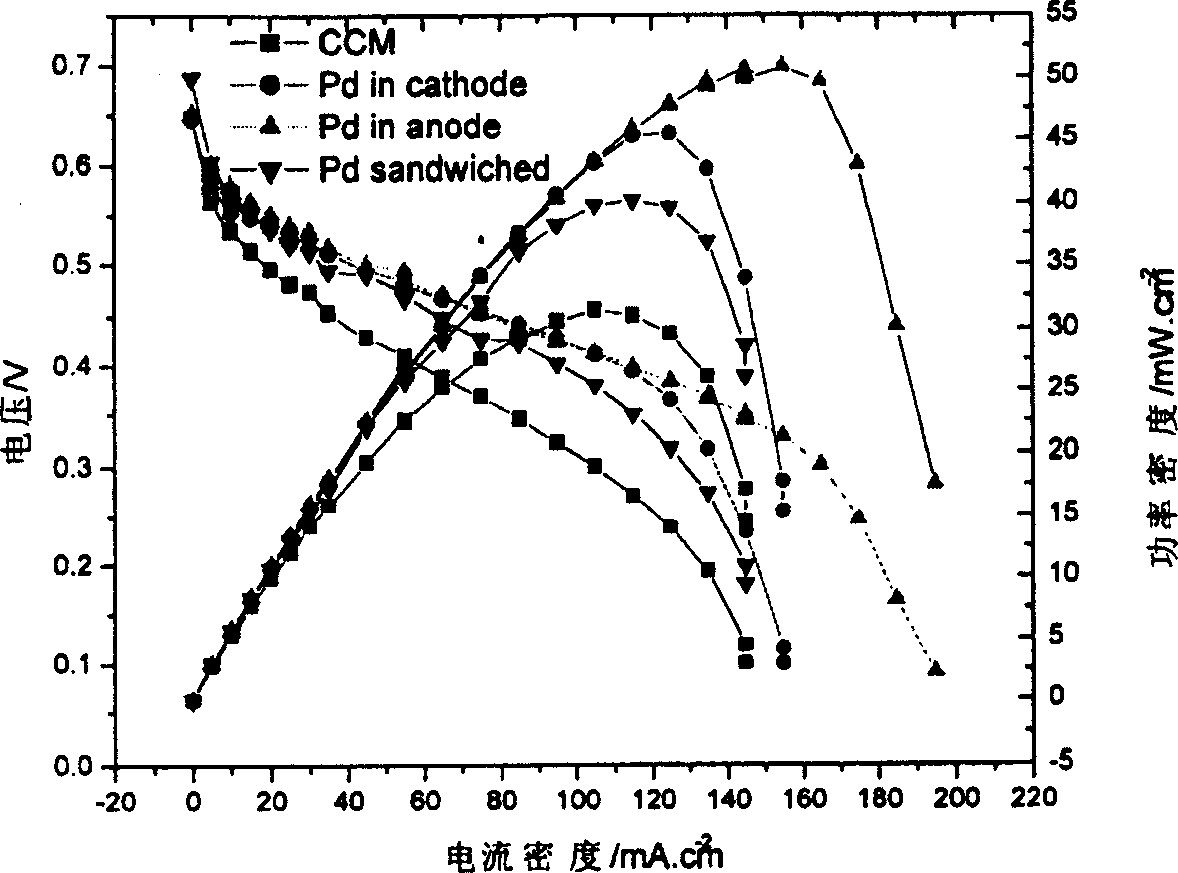

[0056] Electrodes were prepared according to the steps in Example 1. The anode catalyst is Pt / Ru black, and the catalyst loading is 3.7mg / cm 2 , Nafion content is 15%. The cathode catalyst is Pt black, and the catalyst loading is 3.0mg / cm 2 , Nafion content is 5%. After activation, measure the performance of the single cell. The experimental conditions are as follows: the anode feed is 1M methanol aqueous solution at 1ml / min, the cathode feed is oxygen, the flow rate is 4.0ml / s, and the operating temperature is 30°C. Battery performance curve see image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com