Efficient multifunctional lubricant and its prepn

A multi-functional, lubricant technology, which is applied in the direction of lubricating composition, additives, petroleum industry, etc., can solve the problem of single functional effect, instability, and complicated preparation of lubricants, so as to improve the bearing capacity and anti-wear ability of oil film and lubricate Ability, effect stable and long-lasting, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

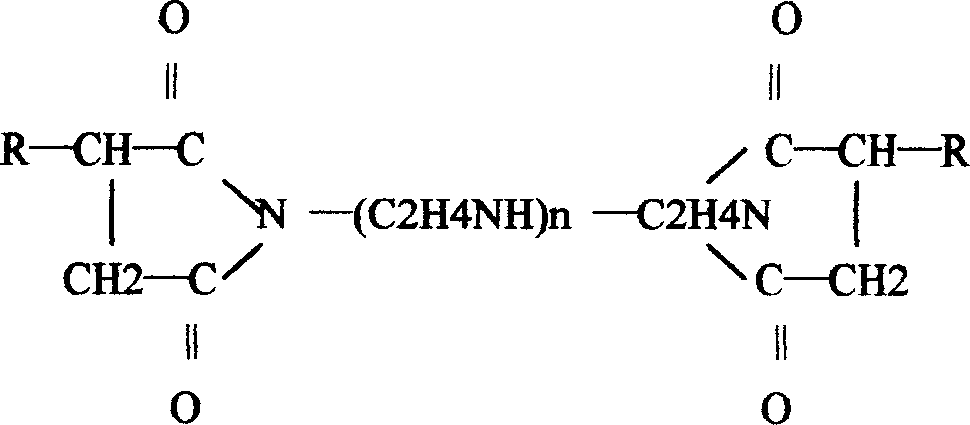

Embodiment 1

[0041] Embodiment 1, a kind of high-efficiency multifunctional lubricant is made of molybdenum disulfide 2kg, graphite 10kg, petroleum additive 10kg with dispersion function, petroleum additive 15kg with anti-wear function, petroleum additive 3kg with neutralization function, has stable Functional petroleum additive 5kg, diluent 55kg, the petroleum additive with dispersion function is to adopt dienyl succinimide in the present embodiment, and the petroleum additive with neutralization function is to adopt high alkali value synthetic calcium sulfonate, has anti- The petroleum additive of grinding function refers to sulfur phosphorus bis-octyl basic zinc salt, and the petroleum additive with stabilizing function refers to polymethacrylate; the present invention firstly takes the raw material according to the formula, and after preliminary inspection, classification, homogenization and dispersion, Grinding, secondary homogenizing and dispersing, filtering, and cooling processing, ...

Embodiment 2

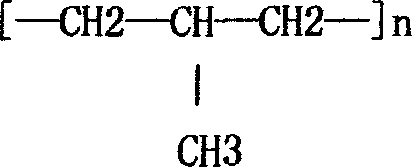

[0042] Embodiment 2, a kind of high-efficiency multifunctional lubricant, is made of molybdenum disulfide 5kg, graphite 5kg, has the petroleum additive 15kg of dispersion function, has the petroleum additive 10kg of anti-wear function, has the petroleum additive 1kg of neutralization function, has stable Functional petroleum additive 8kg, diluent 56kg, the petroleum additive with dispersing function in the present embodiment is to adopt two kinds of mixtures of dienyl succinimide and polyalkenyl succinimide, the petroleum additive with neutralization function It is a mixture of high alkali value synthetic calcium sulfonate and high alkali value petroleum calcium sulfonate, and the petroleum additive with anti-wear function is a mixture of sulfur phosphorus secondary alcohol zinc salt and thiophosphoric acid amine salt, which has a stabilizing function The petroleum additive is mixed with polymethacrylate and polyvinyl n-propyl ether, and the preparation process is the same as i...

Embodiment 3

[0043] Embodiment 3, a kind of high-efficiency multifunctional lubricant is made of molybdenum disulfide 2kg, graphite 5kg, petroleum additive 10kg with dispersing function, petroleum additive 10kg with anti-wear function, petroleum additive 1kg with neutralization function, has stable Functional petroleum additive 5kg, diluent 67kg, the petroleum additive with dispersion function is to adopt three kinds of dienyl succinimide, polyenyl succinimide, monoalkenyl succinimide among the present embodiment Mixing, the petroleum additive with neutralization function is a mixture of three kinds of high alkali value synthetic calcium sulfonate, high alkali value alkyl salicylate calcium, and high alkali value petroleum calcium sulfonate. The petroleum additive with antiwear function refers to Phosphobisoctyl alkaline zinc salt, thiophosphor secondary alcohol base zinc salt, and thiophosphoric acid amine salt are mixed. Petroleum additives with stabilizing functions refer to polymethacry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com