Vacuum high pressure pulse discharge catalyzed chemical heat treatment apparatus and method

A high-voltage pulse discharge and chemical heat treatment technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of slow heating speed of workpiece, different intensity of glow discharge, affecting the surface quality of workpiece, etc. Good surface quality, fast penetration and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

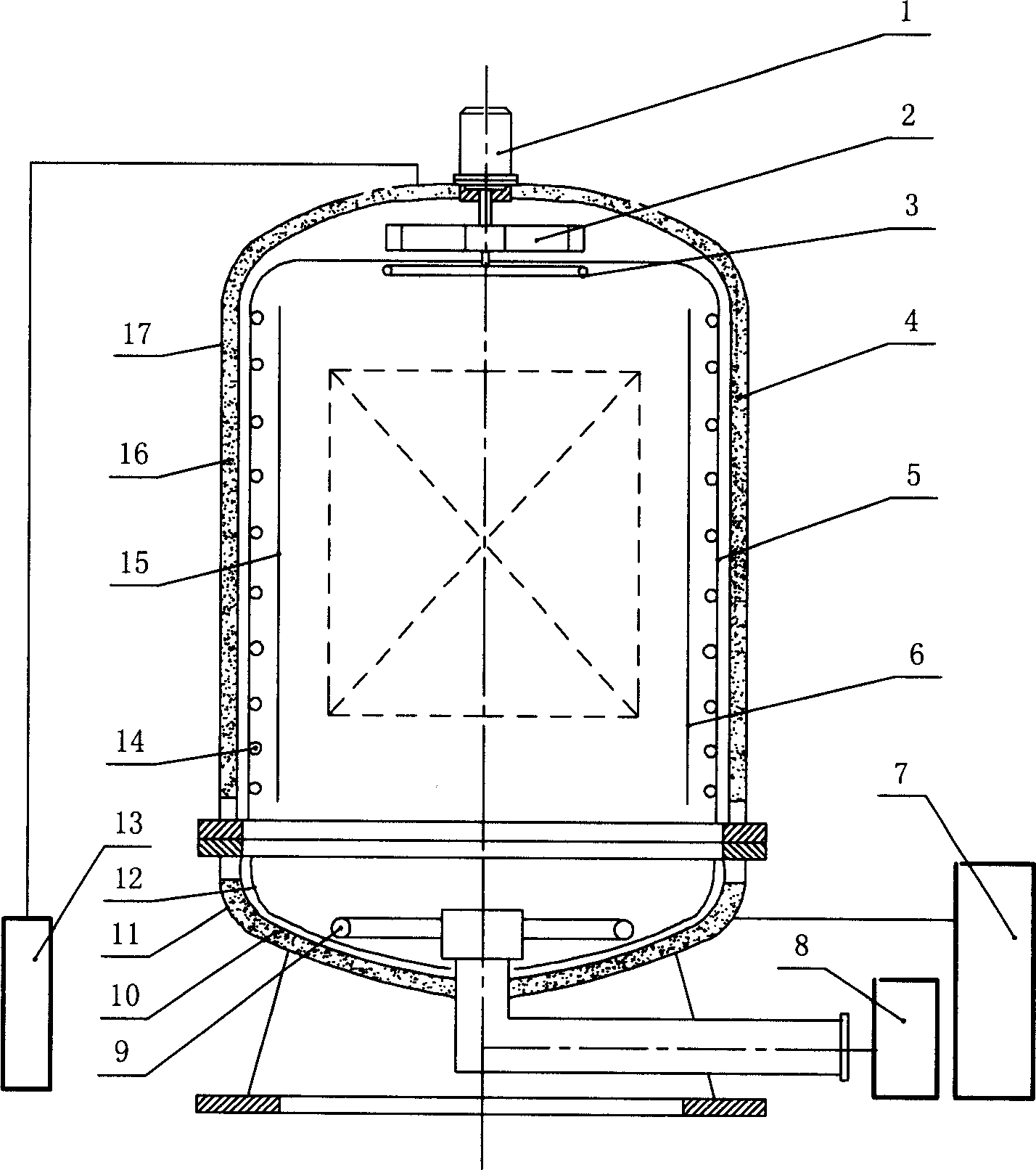

[0011] Put the workpiece in the furnace, and the built-in AC heater 14 directly heats the workpiece to the nitriding temperature. The output voltage of the pulse power supply is 6000 volts, which acts between the catalytic discharge electrode 6 and the catalytic discharge electrode 15 in the furnace to initiate and maintain strong gas ionization. discharge. The pressure in the furnace is 1100Pa, and the nitrogen-containing gas is violently ionized and discharged, which produces a large number of active infiltrated atoms, which penetrate into the workpiece at a high speed. The workpiece is not connected to the electrode, and the workpiece has no potential, so that the workpiece is not affected by ion bombardment and does not produce arcing. The nitriding gas enters the furnace through the gas supply ring pipe 3, and the external vacuum motor 1 is started. Under the action of the fan 2, the nitriding gas is guided through the heat shield 5 and the heat shield 12, from the upper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com