Combined central air conditioning condensation heat recovery utilizating system and method

A central air-conditioning and combined technology, which is applied in heat recovery systems, air-conditioning systems, energy recovery systems for ventilation and heating, etc., and can solve problems such as energy waste, air pollution, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

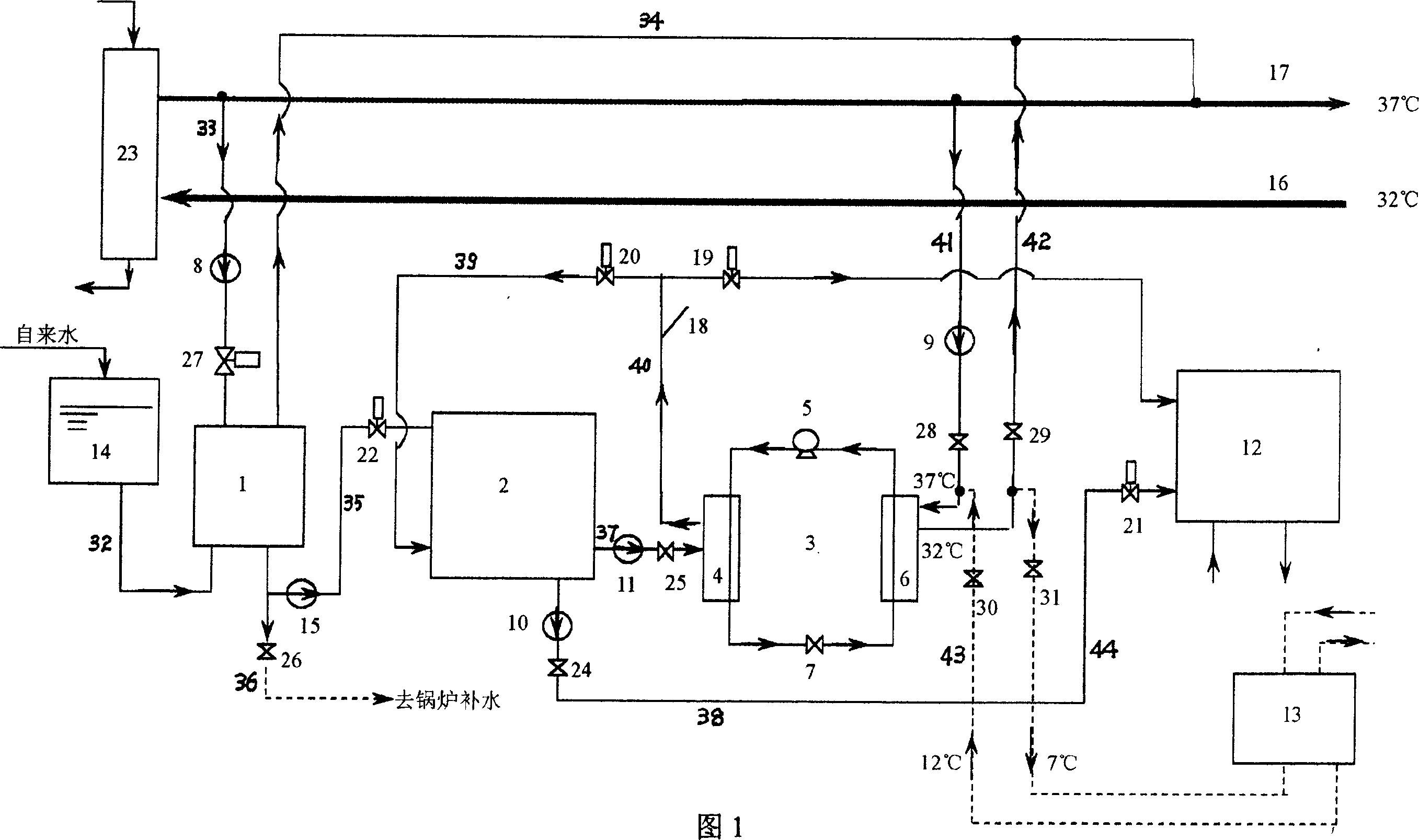

[0011] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] As shown in the figure, the heat recovery system of the present invention has a preheating plate heat exchanger 1, a hot water storage tank 2, a water-water heat pump 3 (by a heat pump compressor 5, a heat pump condenser 4, a heat pump throttle valve 7 and Heat pump evaporator 6), pipeline pump 8, pipeline pump 9, water supply pump 10, circulation pump 11, hotel's original living water tank 12, hotel's original heating plate replacement 13, tap water tank 14, preheating water pump 15, return from the cooling tower The cooling jellyfish pipe 16, the cooling jellyfish pipe 17 to the cooling tower, the thermometer 18, the solenoid valve 19, 20, 21, 22, 27, the condenser 23 of the chiller, the shut-off valve 24, 25, 26, 28, 30, 31 , composed of connecting pipelines 32-44, and the connection relationship is as described above.

[0013]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com