Column for ion chromatograph, suppressor and ion chromatograph

A technology for ion chromatography and separation column, which is applied in the field of ion chromatography columns, suppressors and ion chromatography, and can solve the problems of undisclosed ion chromatography suppressor, failure to meet the performance of component parts, and undisclosed porous ion exchange agent and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] (production of suppressor)

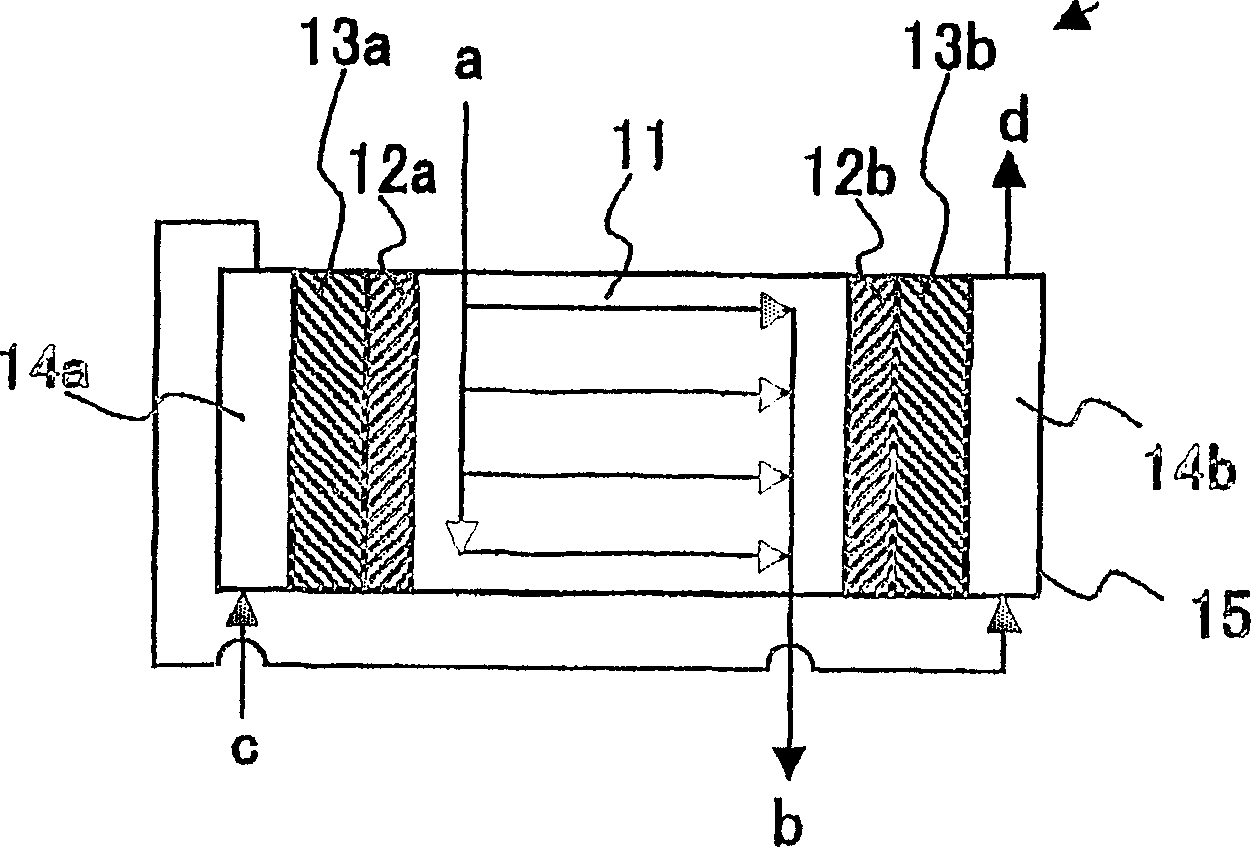

[0069] The above-mentioned organic porous cation exchanger A was cut into a cylindrical shape, and filled in a cylindrical column with an inner diameter of 3 mm so that the length of the packed layer was 10 mm. Nafion 117 (manufactured by Dupont Corporation) as a cation exchange membrane is closely attached to both ends of a horizontal columnar organic porous cation exchanger, and a platinum mesh is provided at both ends of the outer side so as to be in contact with the ion exchange membrane. electrodes, formed in accordance with figure 2 In the way of the flow path shown, a liquid flow nozzle for the effluent from the separation column is installed at this part, and a tube for liquid flow with the electrode chamber is installed, and the production is as follows: figure 2 A suppressor constructed like that.

[0070] (Manufacture of organic porous body B)

[0071] An organic porous body B was produced in the same manner as that of the or...

Embodiment 2

[0078] Embodiment 2 (making of separation column)

[0079] The above-mentioned organic porous anion exchanger B was cut and filled in a column with an inner diameter of 4.0 mm and a length of 150 mm. At a liquid flow rate of 1ml / min, pass through 0.5N sodium hydroxide aqueous solution for 20 minutes, then pass pure water at a rate of 1ml / min, carry out water washing for 30 minutes, and form an anion exchanger in the form of OH, Then, a 1:1 mixed aqueous solution of 3.5 mM sodium carbonate and 0.4 mM sodium bicarbonate was passed through at 1.5 ml / min for 20 minutes to equilibrate it to obtain a separation column. Equilibrium treatment was carried out in a constant temperature bath at 35°C. The fluid flow pressure at the end of the equalization treatment was 0.45 MPa.

Embodiment 3

[0080] Embodiment 3 (making of concentrating column)

[0081] The above-mentioned organic porous ion exchanger C was cut and filled in a column with an inner diameter of 3.0 mm and a length of 10 mm. At a flow rate of 1ml / min, pass a 0.5N sodium hydroxide aqueous solution for 10 minutes, then wash with pure water at a rate of 1ml / min for 20 minutes to form the anion exchanger into an OH form, and then A 1:1 mixed aqueous solution of 3.5 mM sodium carbonate and 0.4 mM sodium bicarbonate was passed through at 2 ml / min for 20 minutes, and equilibrated to obtain a concentrated column. Equilibrium treatment was carried out in a constant temperature bath at 35°C. The fluid flow pressure at the end point of the equilibration treatment was 0.05 MPa.

[0082] (Performance Evaluation of Concentrator Column)

[0083] The concentration column obtained in the above manner is used for the concentration column, and the following column is used for the separation column, that is, in a colu...

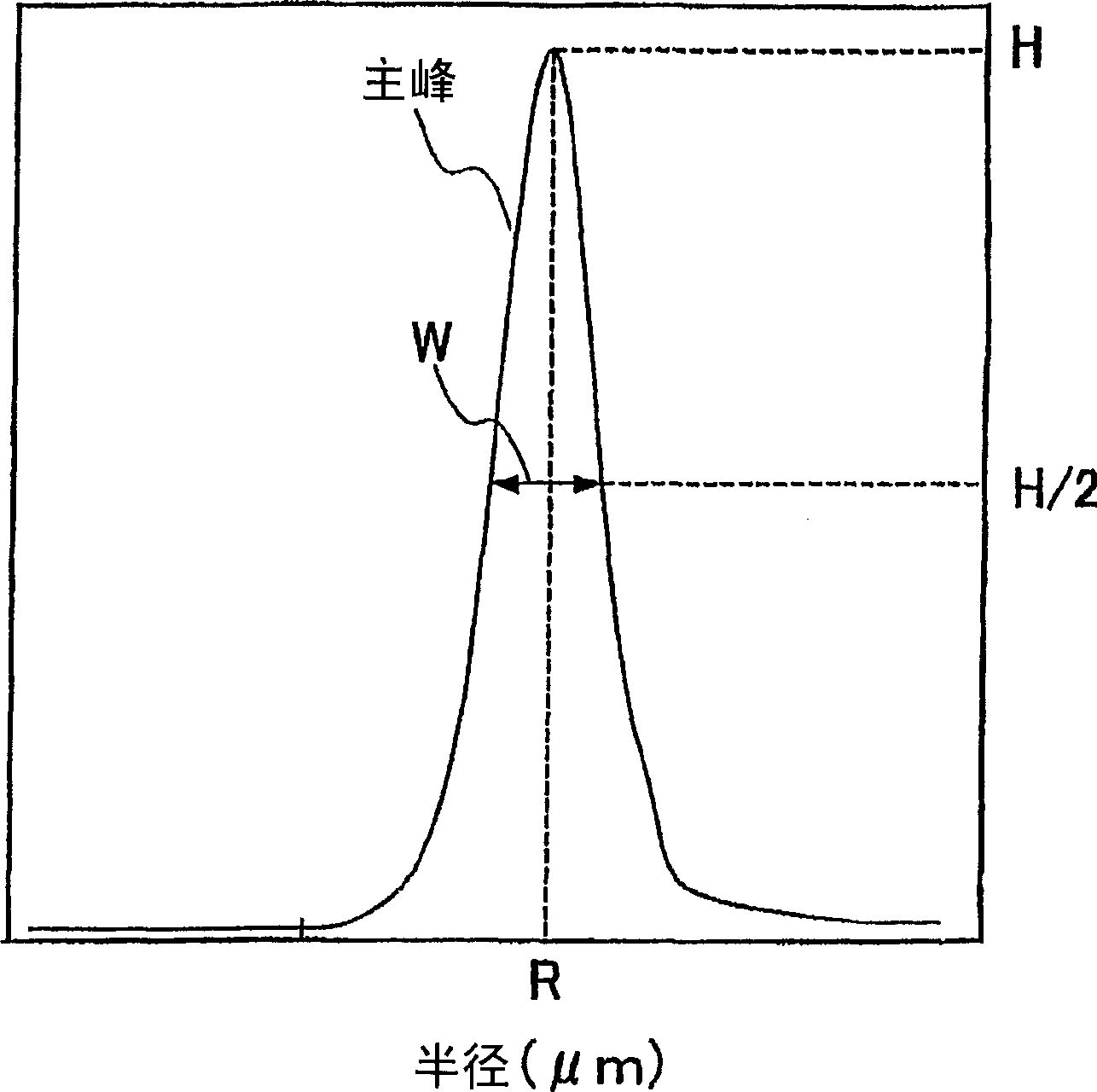

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com