Titanium dioxide nanometer pipe composite separating membrane, its preparation and use thereof

A nanotube composite and titanium dioxide technology, applied in the field of environmental pollution control, can solve the problems of membrane pollution, small loading area, and high cost of inorganic membranes, and achieve the effects of large photocatalytic activity, high removal efficiency, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] For the treatment of organic pollutant wastewater with small molecular size and small amount of wastewater, such as pesticides, when the permeation flux of the composite separation membrane is required to be small, the titanium dioxide nanotube composite separation membrane prepared under the following conditions can be applied. This composite separation Membranes can meet the needs of laboratory research.

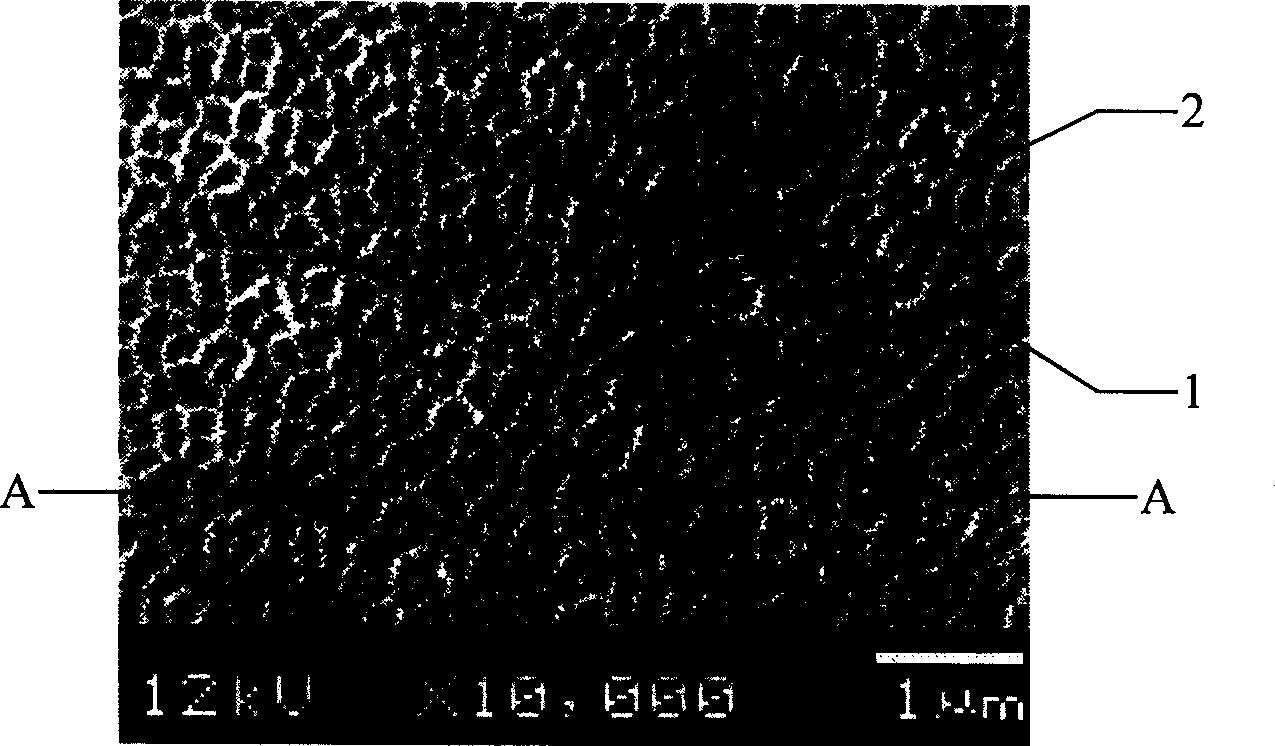

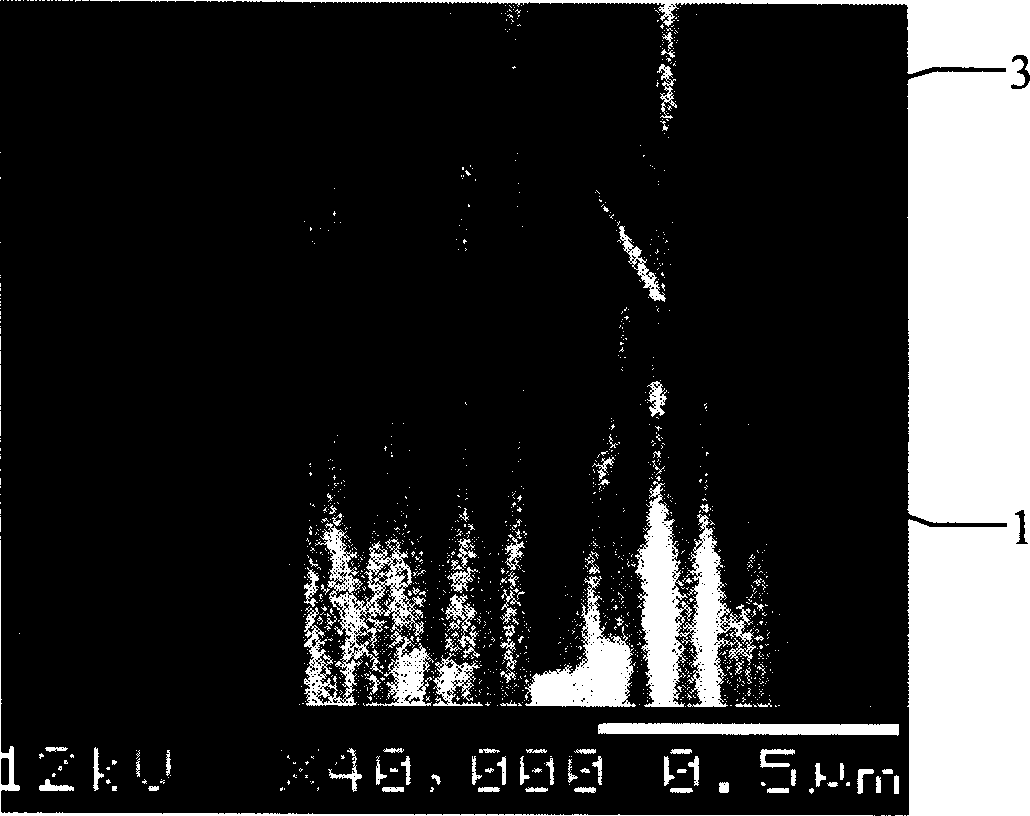

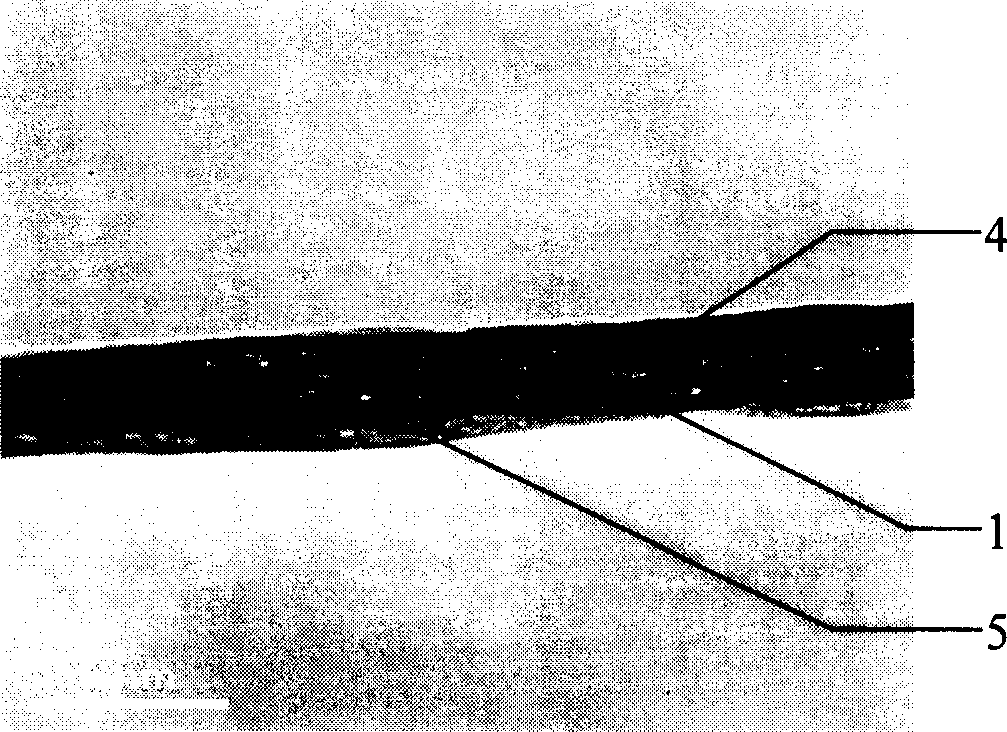

[0080] Al with a pore size of 20nm, a diameter of 25mm, a thickness of 50μm, a pore spacing of 40-80nm, and a porosity of 30% 2 o 3 The inorganic membrane is used as a carrier to prepare a titanium dioxide nanotube composite separation membrane with a pore size of 5-10 nm. The steps are:

[0081] The first step, the pretreatment of the carrier

[0082] al 2 o 3 The inorganic diaphragm was ultrasonically cleaned with deionized water for 20 minutes, then washed with acetone and deionized water for 10 minutes, dried in an oven at 50°C, cooled to room temperature, a...

Embodiment 2

[0089] For the treatment of wastewater with large molecular size organic pollutants, such as dyes, polychlorinated biphenyls, etc., the titanium dioxide nanotube composite separation membrane prepared under the following conditions can be applied. This composite separation membrane can meet the requirements of laboratory research and a small amount of actual wastewater treatment need.

[0090] Al with a pore size of 100nm, a diameter of 47mm, a thickness of 60μm, a pore spacing of 30-60nm, and a porosity of 40% 2 o 3 The inorganic membrane is used as a carrier to prepare a titanium dioxide nanotube composite separation membrane with a pore size of 40-50 nm. The steps are:

[0091] The first step, the pretreatment of the carrier

[0092] al 2 o 3 The inorganic diaphragm was ultrasonically cleaned with deionized water for 15 minutes, then washed with acetone and deionized water for 10 minutes, dried in an oven at 100°C, cooled to room temperature, and set aside.

[0093] Th...

Embodiment 3

[0099] For the treatment of organic pollutant wastewater with large molecular size, such as dye and surfactant wastewater, the titanium dioxide nanotube composite separation membrane prepared under the following conditions can be applied. This composite separation membrane can meet the requirements of laboratory research and a small amount of actual wastewater treatment. need.

[0100] Al with a pore size of 200nm, a diameter of 47mm, a thickness of 60μm, a pore spacing of 20-50nm, and a porosity of 50% 2 o 3 The inorganic membrane is used as a carrier to prepare a titanium dioxide nanotube composite separation membrane with a pore size of 50-80 nm. The steps are:

[0101] The first step, the pretreatment of the carrier

[0102] al 2 o 3 The inorganic diaphragm was ultrasonically cleaned with deionized water for 20 minutes, then washed with acetone and deionized water for 20 minutes, dried in an oven at 50°C, cooled to room temperature, and set aside.

[0103] The second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com