Nanometer gas-sensing material of ternary composite metal oxide and production thereof

A ternary composite, gas-sensing material technology, applied in the field of ternary composite metal oxide nano gas-sensing materials and their preparation, can solve the problems of complex operation steps, unsatisfactory sensitivity and selectivity, etc., and achieves controllable reaction conditions, The effect of mild experimental conditions and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

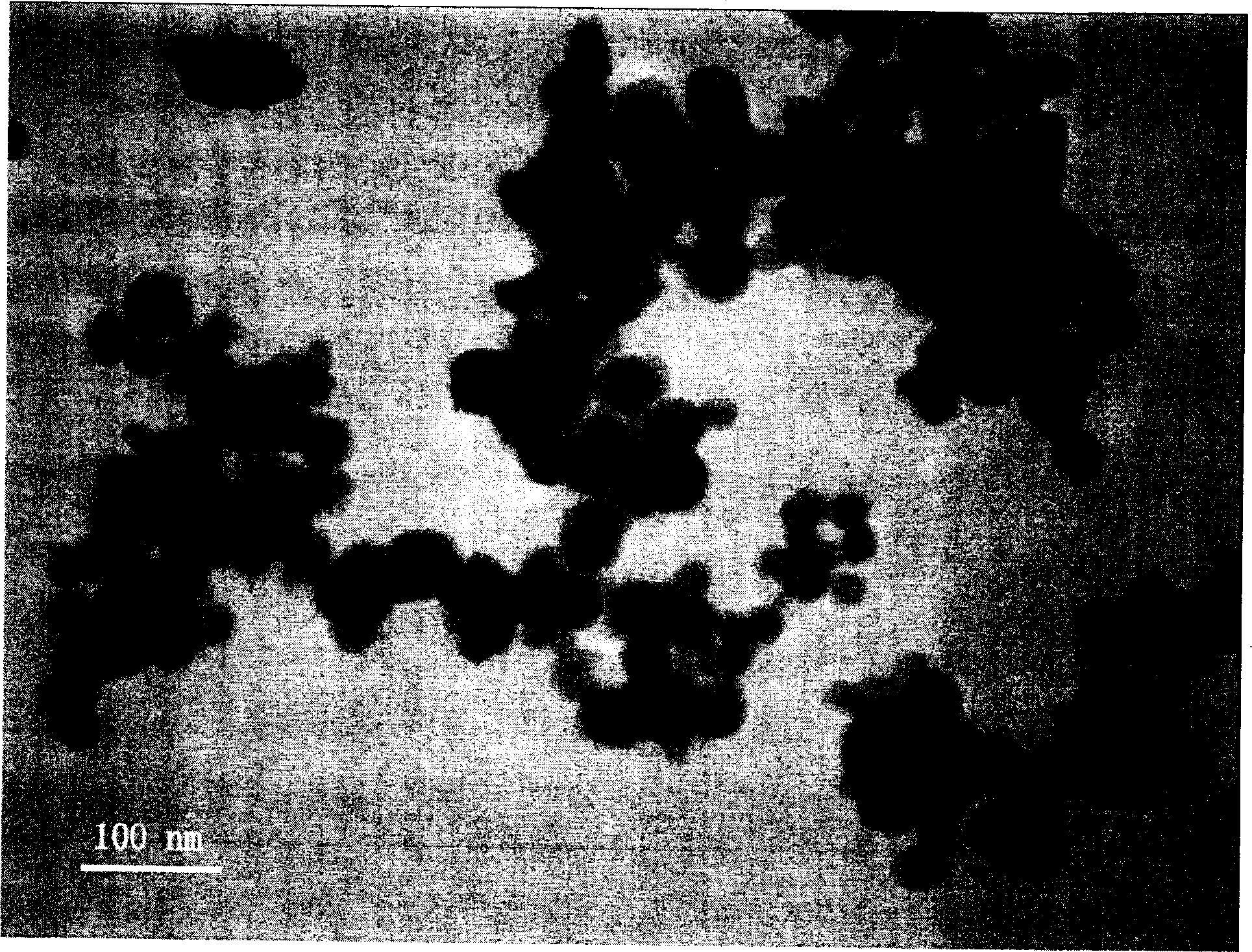

[0018] Al 2 o 3 -ZnO-SnO 2 preparation of

[0019] Accurately weigh 5.2602g Zn(NO 3 ) 2 ·6H 2 O and 2.9747g SnCl 4 ·5H 2 O was dissolved in 500mL deionized water to form a mixed salt solution, and under strong stirring at a speed of 400rpm, a dilute ammonia solution with a concentration of about 12% was slowly added dropwise to the above mixed solution until the pH value was 8.0 to form a precipitated precursor. Add 0.7658g AlCl immediately after the precipitation is complete 3 ·6H 2O, and under strong stirring at a speed of 400rpm, slowly drop a 12% dilute ammonia solution to adjust the pH value to 9.0, secondary precipitation, stand for aging for 24hrs, filter, and fully wash until there is almost no Cl in the filtrate - and NO 3 - , the obtained precipitate was dried at 100°C for 5hr, and then calcined in air atmosphere at 600°C for 6hr with a heating rate of 3°C / min to obtain Al 2 o 3 -ZnO-SnO 2 Composite metal oxide powder, where Zn 2+ / Sn 4+ The molar rat...

Embodiment 2

[0021] With embodiment 1, just AlCl 3 ·6H 2 The amount of O added was changed to 1.6165g, and Al 2 o 3 -ZnO-SnO 2 Composite metal oxide powder, where Zn 2+ / Sn 4+ The molar ratio is 2:3, Al 2 o 3 The mass percent of composite oxide is 10%. The average particle size of the composite material is about 38nm, and the specific surface area is 100.5m 2 / g.

Embodiment 3

[0023] With embodiment 1, just AlCl 3 ·6H 2 The amount of O added was changed to 3.6374g, and Al 2 o 3 -ZnO-SnO 2 Composite metal oxide powder, where Zn 2+ / Sn 4+ The molar ratio is 2:3, Al 2 o 3 The mass percent of composite oxide is 20%. The average particle size of the composite material is about 60nm, and the specific surface area is 56.7m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com