High strength connecting method for TiAl base alloy charging turbine and steel shaft

A supercharged turbine and connection method technology, applied in the direction of welding medium, metal processing, welding equipment, etc., can solve the problems of low joint strength, high joint brittleness, joint cracking, etc., to solve the problem of long operation period, improve high temperature mechanical properties, The effect of raising the operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

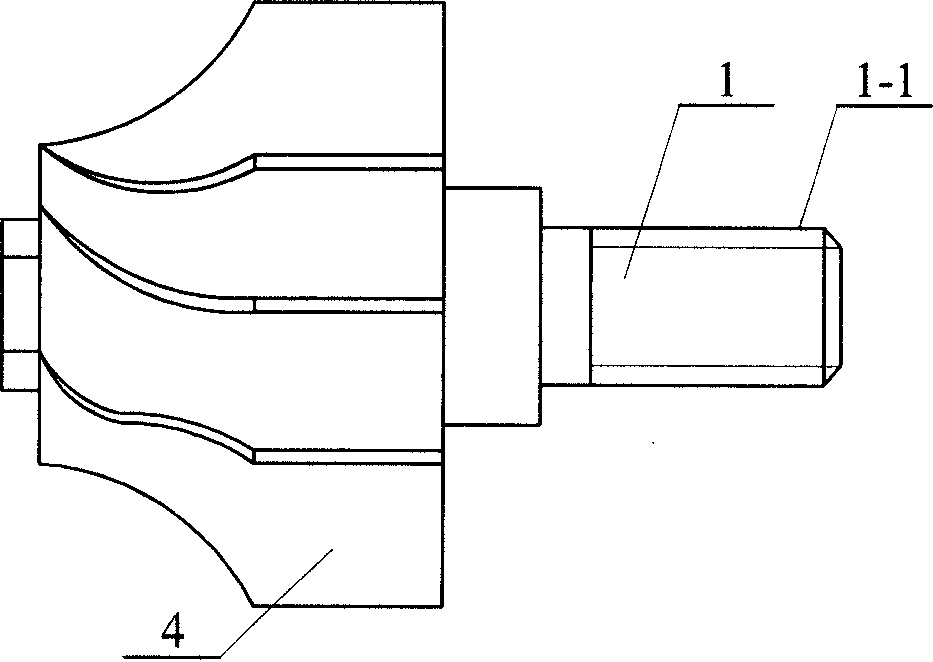

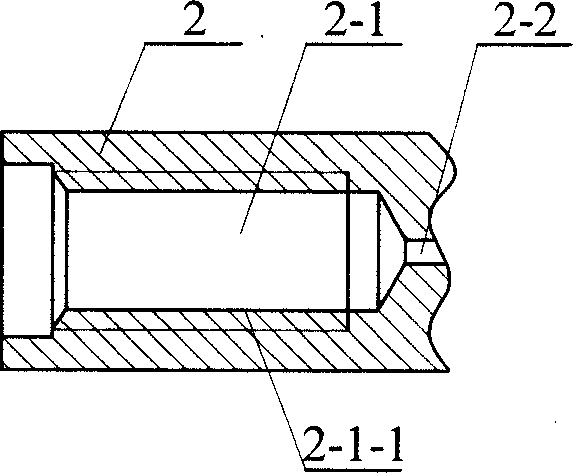

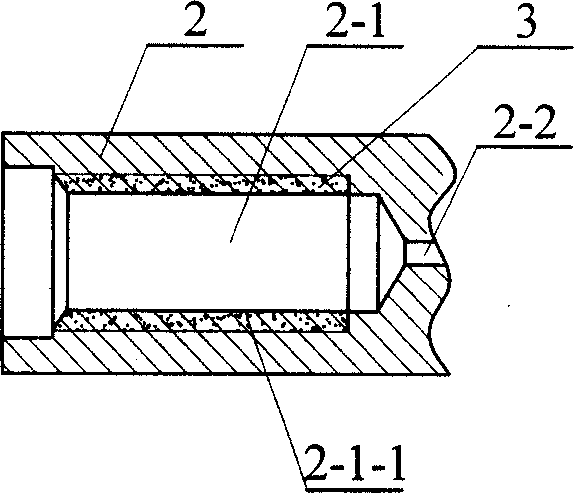

[0006] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 Describe the present embodiment, the high-strength connection method of the TiAl-based alloy supercharged turbine and the steel shaft of the present embodiment is completed by the following steps: a, process the external thread 1-1 on the outer wall of the TiAl-based alloy supercharged turbine connecting shaft 1, Process the steel shaft 2 along the axial direction to form an internally threaded sleeve 2-1 that matches the externally threaded connecting shaft of the TiAl-based alloy turbocharger 4 and an axial process through hole 2-2 that communicates with the internally threaded sleeve 2-1; b. Coating AgCuNiLi solder paste 3 on the inner wall of the internally threaded sleeve 2-1, said AgCuNiLi solder paste 3 is mixed with AgCuNiLi solder powder and binder according to the ratio of 9 to 11:1 by weight Prepared by stirring, the AgCuNiLi solder powder is com...

specific Embodiment approach 2

[0007] Specific implementation mode two: combination figure 1 , figure 2 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is: in step a of this embodiment, the outer wall of the TiAl-based alloy supercharger turbine connection shaft 1 is processed with a fine-pitched external thread, and the steel shaft 2 is threaded along the In the axial direction, a fine-thread internal thread sleeve matching the fine-thread external thread connecting shaft of the TiAl-based alloy turbocharger 4 and an axial process through hole 2-2 communicating with the fine-pitch internal thread sleeve are processed. The use of fine threads can ensure the connection strength and rigidity between the TiAl-based alloy turbocharger 4 and the steel shaft 2 .

specific Embodiment approach 3

[0008] Specific embodiment three: the difference between this embodiment and specific implementation one is: in the b step of this embodiment, the AgCuNiLi solder paste 3 is coated on the inner wall of the fine tooth internal thread sleeve, and the AgCuNiLi solder paste 3 It is prepared by mixing and stirring AgCuNiLi solder powder and binder according to the weight ratio of 9:1, and the AgCuNiLi solder powder is composed of the following components according to weight percentage: Cu: 22.6%, Ni: 4.4% , Li: 0.9%, and the remainder of Ag, the adhesive is prepared by mixing and stirring hydroxyethyl cellulose and distilled water according to a weight ratio of 1:100. The AgCuNiLi solder paste 3 made with the above technical parameters is suitable for the condition that the diameter of the connecting shaft 1 of the TiAl-based alloy turbocharger is not large.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com