Multipurpose new type beta type titanium alloy

A titanium alloy, multi-purpose technology, applied in the field of multi-purpose β-type titanium alloy, can solve the problems of insufficient elasticity, restricting the widespread promotion of golf, and insufficient elasticity of the hitting panel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

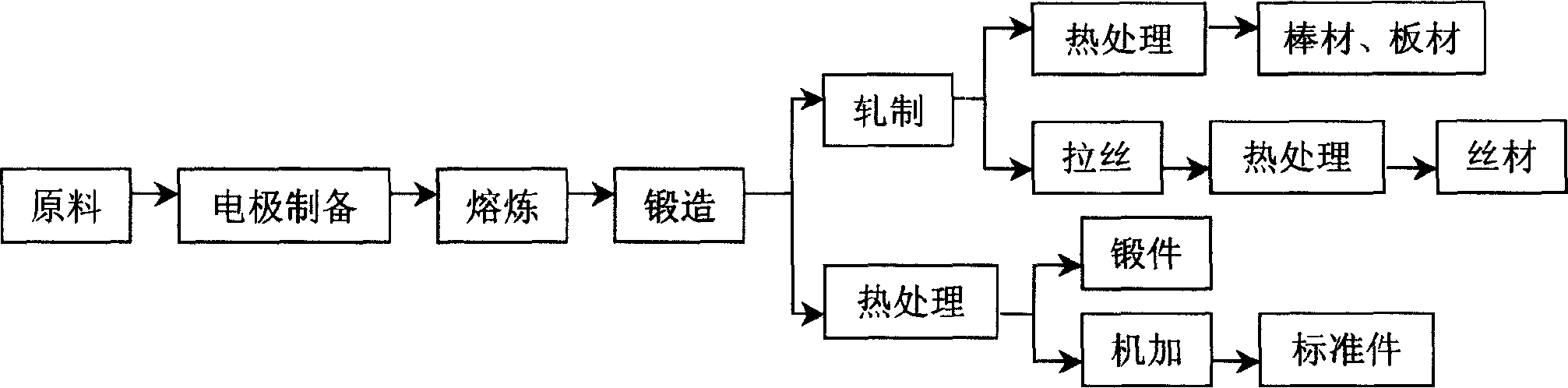

[0009] The preparation method of this type titanium alloy:

[0010] First, mix titanium sponge, aluminum vanadium alloy, aluminum beans or aluminum foil in a certain proportion to form an alloy material, press it into an electrode block with a hydraulic press, and then use a vacuum consumable arc melting furnace to melt it into an ingot for the second time, and then forge, Manufactured into forgings through grinding, heat treatment and other processing procedures; or manufactured into plates through forging, grinding, rolling, heat treatment and other processing procedures; or manufactured into bars, Wire, profiles; or manufactured into standard parts or components through forging, grinding, heat treatment, machining and other processing procedures.

[0011] state

Embodiment 1

[0013] Using grade 1 sponge titanium, aluminum vanadium 85 and aluminum beans as raw materials, according to the nominal composition of Ti-22V-4Al (wt%) for proportioning, after mixing, pressing into electrode blocks, and then welding the electrode blocks with argon arc Methods Welded into electrodes for smelting, smelted twice into ingots in a vacuum consumable arc melting furnace referring to the TC4 titanium alloy melting process, the weight percentage of the secondary ingot of titanium alloy was composed of: vanadium 22%, aluminum 4%, the balance for titanium. Use a hydraulic press or an air hammer to forge the ingot at 1050-1150°C, and then turn it into a Φ110mm round billet after repeated upsetting. Then precision forging is carried out below 950°C to become a round billet of Φ45mm. Finally, it is rolled into Φ8mm wire rod after machine peeling, grinding and repairing, and then ground or repaired to remove scale, and then rolled into Φ2mm wire rod through roller die dra...

Embodiment 2

[0015] Using grade 1 sponge titanium, aluminum vanadium 85 and aluminum beans as raw materials, according to the nominal composition of Ti-22V-4Al (wt%) for proportioning, after mixing, pressing into electrode blocks, and then welding the electrode blocks with argon arc Methods Welded into electrodes for smelting, smelted twice in a vacuum consumable arc melting furnace to form ingots, the weight percent composition of titanium alloy secondary ingots was: 22% vanadium, 4% aluminum, and the balance was titanium. Use a hydraulic press or an air hammer to forge the ingot at 1050-1150°C, and then turn it into a δ50mm square slab after repeated upsetting. Then rolling is carried out below 950° C. to form a slab of δ5 mm. Finally, after sandblasting, repairing, and pickling, the plate with the required thickness is cold-rolled, and after vacuum annealing or vacuum solution aging treatment, it becomes a finished plate for golf head hitting panels or other uses.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com