Method for synthesizing chain-like nanometer structure type cadmium selenide

A nanostructure, cadmium selenide technology, applied in the field of nanomaterials, can solve problems such as inability to prepare nanostructures, and achieve the effects of environmental friendliness, convenient operation, and prevention of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

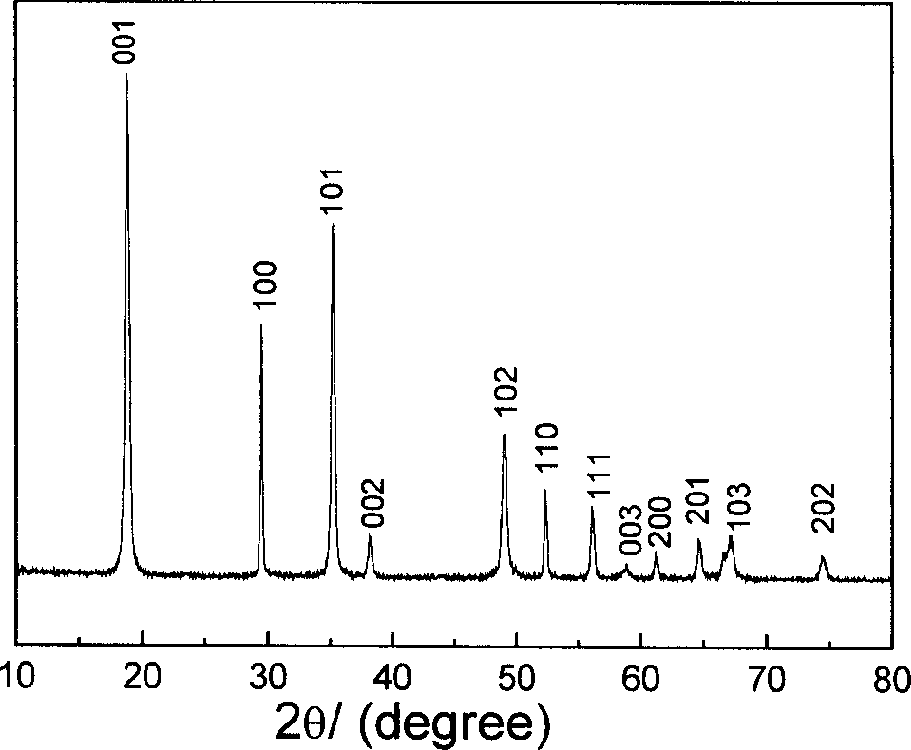

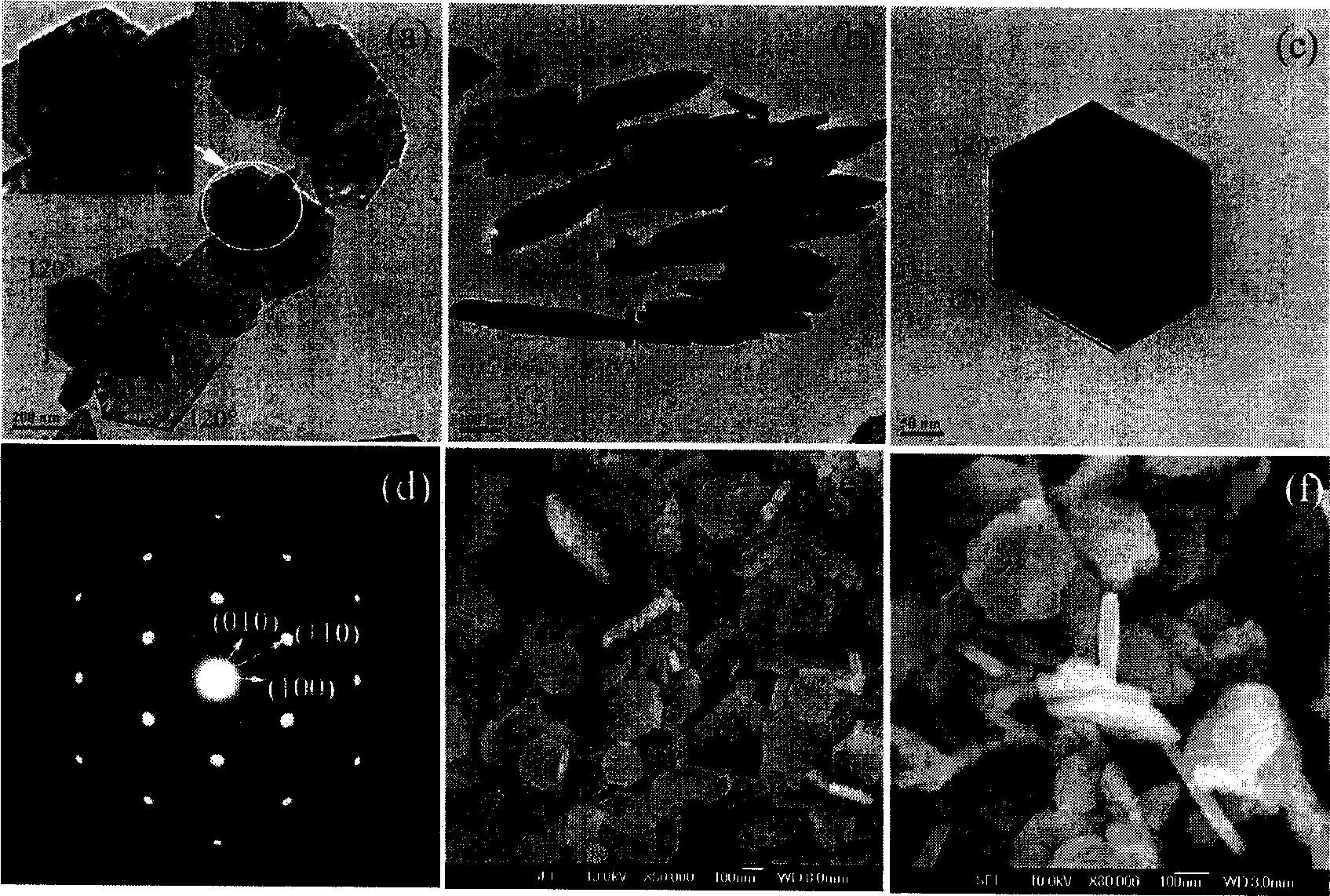

[0032] First prepare 50 mL of Cd(NO 3 ) 2 aqueous solution and 10 mL of 0.006M NaOH aqueous solution; then the NaOH solution was added dropwise to Cd(NO 3 ) 2 Cd(OH) is formed in solution 2 The colloidal suspension was stirred by magnetic force for 1 hour, then filtered and washed with deionized water for 3 times to remove excess hydroxide ions. The collected amorphous Cd(OH) 2 Disperse in 70mL sodium nitrate solution with a concentration of 0.1M, put it into a polytetrafluoroethylene-lined stainless steel reaction kettle, place it in an oven, and keep it at 200°C for 20 hours; after cooling to room temperature, the white precipitate is suction filtered Collected, washed three times with deionized water, washed twice with absolute ethanol, and finally dried in a vacuum oven at 60°C for 4 hours. The prepared Cd(OH) 2 The hexagonal nanoplatelets were stored in a desiccator for later use. The above-prepared Cd(OH) 2 Hexagonal nanoplatelets were ultrasonically dispersed in...

Embodiment 2

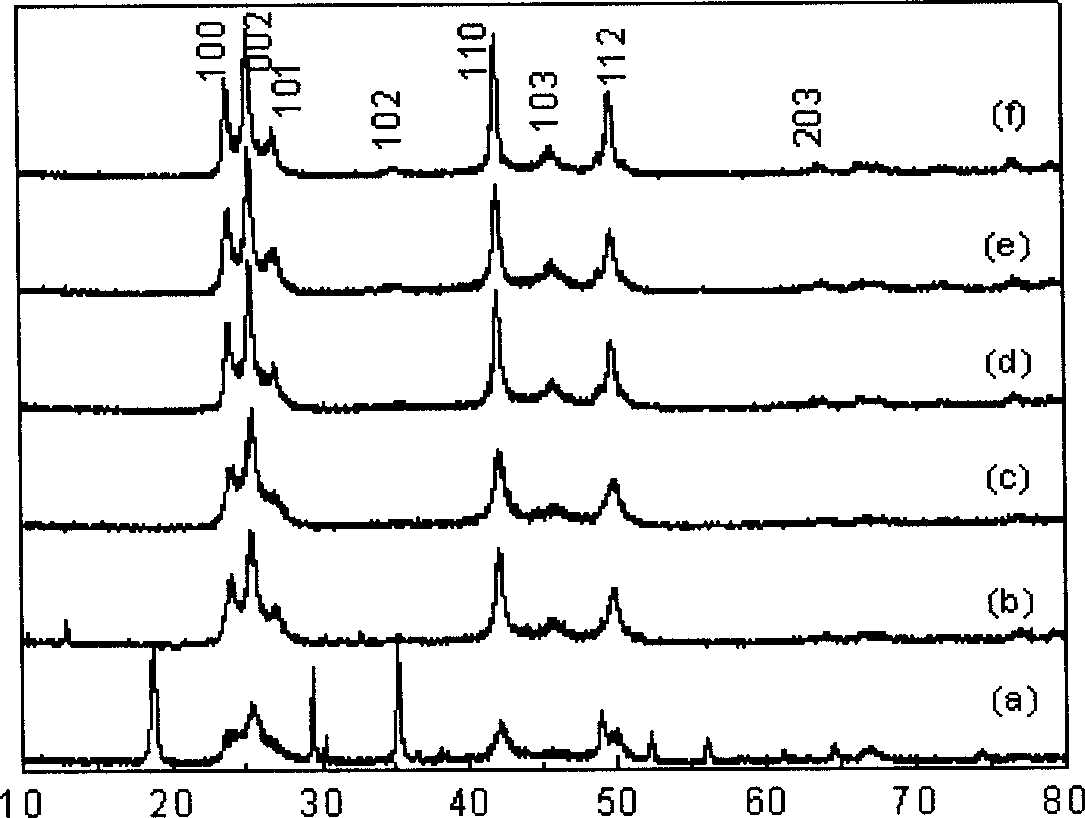

[0034] The above-prepared Cd(OH) 2 Hexagonal nanoplatelets were ultrasonically dispersed in 65mL of deionized water to form a white suspension with a concentration of 0.0006M; 5mL of sodium selenosulfate solution with a concentration of 0.2M was added and stirred evenly by magnetic force; In a stainless steel reaction kettle lined with vinyl fluoride, place it in an oven and keep it warm at 140°C for 10 hours. After cooling to room temperature, it was collected by suction filtration, washed three times with deionized water and twice with absolute ethanol, and finally dried in a vacuum oven at 60°C for 4 hours. All the other are with embodiment 1. image 3( d) and Figure 5( e) are the XRD spectrum and TEM morphology photographs of the cadmium selenide nanocrystals prepared in this example, respectively. It can be found that cadmium selenide is all wurtzite, and the grain size is calculated by the Scherrer formula to be 25nm. The product is a hexagonal structure formed by th...

Embodiment 3

[0036] The above-prepared Cd(OH) 2 Hexagonal nanoplatelets were ultrasonically dispersed in 65mL of deionized water to form a white suspension with a concentration of 0.0006M; 5mL of sodium selenosulfate solution with a concentration of 0.2M was added and stirred evenly by magnetic force; A stainless steel reactor lined with vinyl fluoride was placed in an oven and kept at 100°C for 10 hours. After cooling to room temperature, it was collected by suction filtration, washed three times with deionized water and twice with absolute ethanol, and finally dried in a vacuum oven at 60°C for 4 hours. All the other are with embodiment 1. image 3( c) and Figure 5( d) are the XRD patterns and TEM morphology photos of the cadmium selenide nanocrystals prepared in this example, respectively. It can be found that cadmium selenide is already wurtzite, which is a surprising result, because the room temperature phase is sphalerite, and wurtzite has been prepared at such a low temperature....

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com