Titanium dioxide nano material film and preparation method thereof

A material film and nanomaterial technology, which is applied in the field of low-dimensional nanomaterial film preparation, can solve problems such as being unsuitable for large-scale production, poor film stability, and unfavorable large-scale production, so as to strengthen neck connections, promote industrialization, and expand use. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

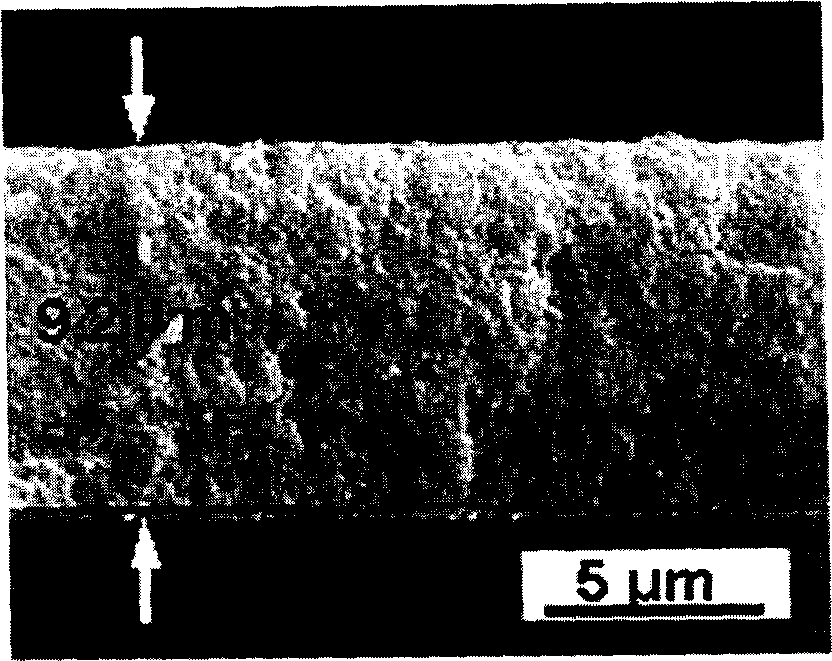

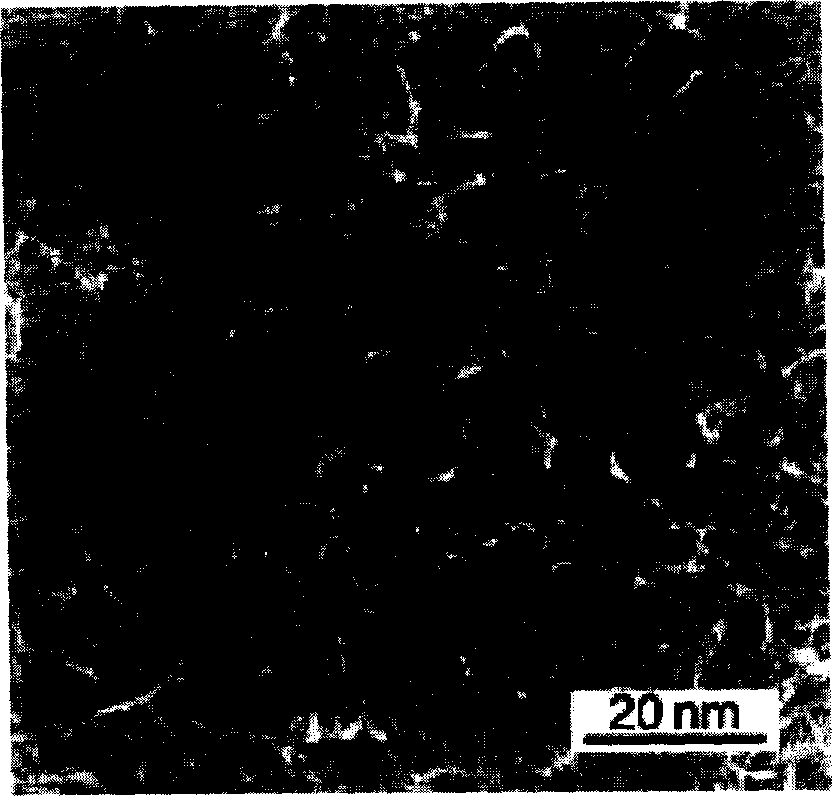

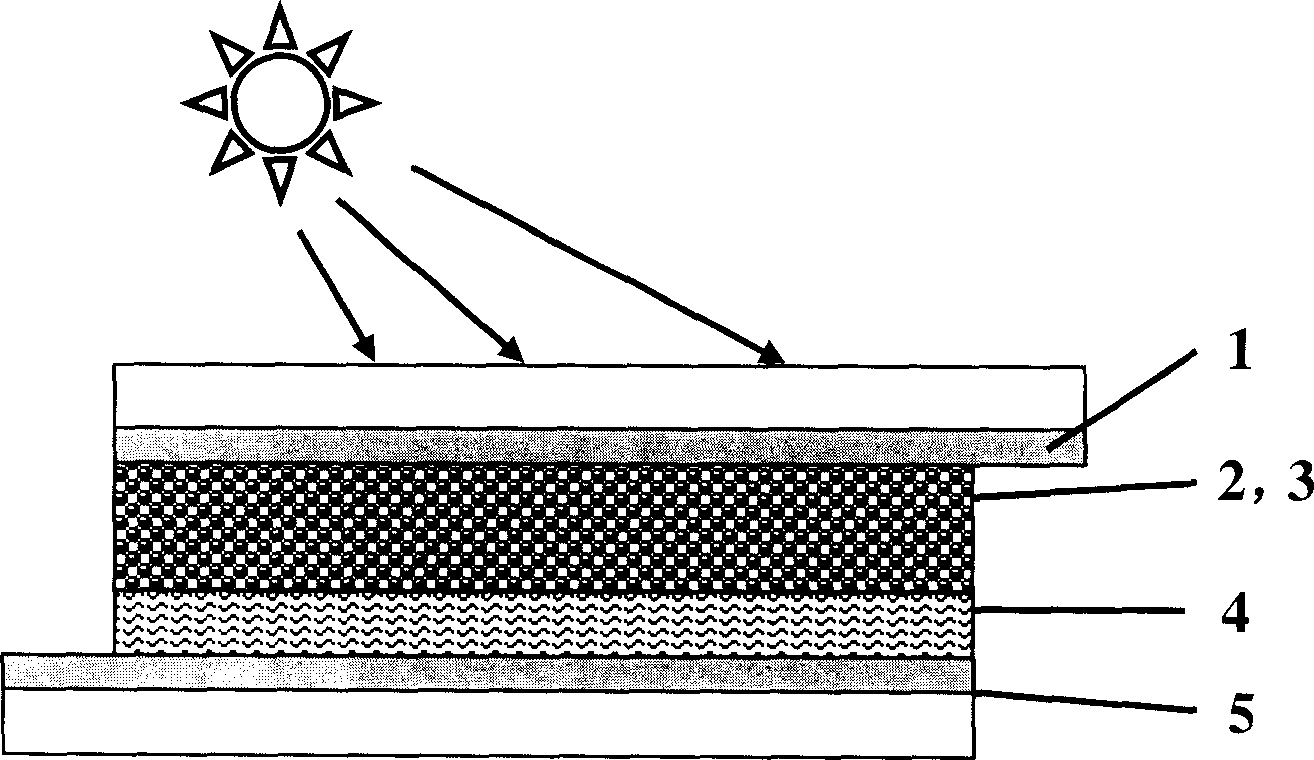

Embodiment 1

[0029] Put 0.5wt% PVB surfactant into dehydrated alcohol, ultrasonic 30min, surfactant is fully dissolved, then 5wt% titanium oxide nanocrystals (average particle diameter 25nm), 0.8wt%Ti(SO 4 ) 2 The electrolytes were put into the solution one by one, and stirred evenly by ultrasonic. Stainless steel is used as the anode, and the cleaned transparent ITO conductive glass is used as the cathode. A constant voltage power supply was used as the power supply device, the deposition voltage was 5V / cm, and the deposition time was 30 minutes. Finally, a titanium oxide nanocrystalline film with a flat surface, uniform dispersion, and a thickness of 9.2 μm was obtained on the cathode substrate. The film is then heat-treated at 500° C. for 2 hours to obtain the final nanocrystalline titanium oxide film. Dye-sensitized solar cells are assembled with the titanium oxide nanocrystalline film, the dye is polypyridine ruthenium carboxylate, and the electrolyte is I 2 The acetocyanide solut...

Embodiment 2

[0031] Put 1wt% PVA surfactant into dehydrated alcohol, ultrasonic 30min, surfactant is fully dissolved, then 10wt% titanium oxide nanotubes (average outer diameter 10nm, inner diameter 5nm), 2wt% Zn (NO 3 ) 2 The electrolytes were put into the solution one by one, and stirred evenly by ultrasonic. Stainless steel is used as the anode, and the cleaned transparent FTO conductive glass is used as the cathode. A constant voltage power supply was used as the power supply device, the deposition voltage was 20 V / cm, and the deposition time was 20 minutes. Finally, a titanium oxide nanotube film with a flat surface, uniform dispersion, and a thickness of 12 μm is obtained on the cathode substrate. The film is then heat-treated at 450° C. for 2 hours to obtain the final titanium oxide nanotube film. Dye-sensitized solar cells are assembled with the titanium oxide nanotube film, the dye is polypyridine ruthenium carboxylate, and the electrolyte is I 2 +LiI+TBP (tetra-tert-butylpyri...

Embodiment 3

[0033] Put 3wt% SDS surfactant into dehydrated alcohol, ultrasonic 30min, surfactant is fully dissolved, then 15wt% titanium oxide nanorods (average outer diameter 15nm), 4wt%Ni(NO 3 ) 2 The electrolytes were put into the solution one by one, and stirred evenly by ultrasonic. Stainless steel is used as the anode, and the cleaned transparent flexible ITO polymer is used as the cathode. A constant voltage power supply was used as the power supply device, the deposition voltage was 40V / cm, and the deposition time was 10 minutes. Finally, a titanium oxide nanorod film with a flat surface, uniform dispersion, and a thickness of 10.5 μm was obtained on the cathode substrate. The film was then subjected to microwave treatment for 1 h to obtain the final titanium oxide nanorod film. Dye-sensitized solar cells were assembled with the titanium oxide nanorod film, the dye was polypyridine ruthenium carboxylate, and the electrolyte was I 2 The acetocyanide solution of +LiI+TBP (tetra-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com