Automatic stepless speed changing transmission device with big torque ratio

An automatic speed change and transmission technology, applied in transmission, fluid transmission, transmission box, etc., can solve the problems of high requirements on materials and processing accuracy, short service life, cumbersome structure, etc., and achieve rationalization of structure and working conditions, The effect of reducing production cost and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

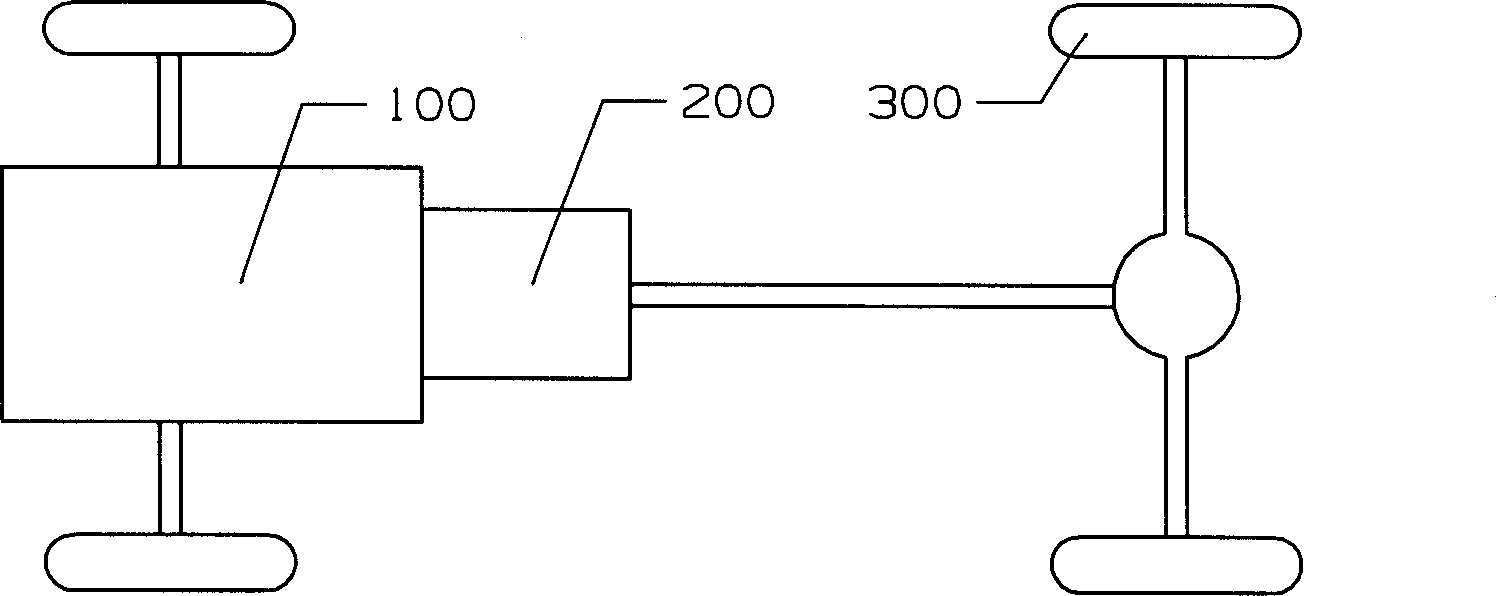

[0068] See Figure 1A , The figure schematically shows the structure of the automobile drive system, including a power source 100, a transmission 200 and a load 300 (ie wheels, etc.). The power source 100 is an engine, an electric motor or other prime movers. For ease of description, the present invention uses an engine As a power source. The transmission device 200 is installed between the power source 100 and the load 300, and the power output by the power source 100 is transferred to the wheels 300 to rotate after being torque-changed and shifted by the transmission device 200, thereby driving the vehicle forward or backward. The present invention improves the transmission device 200 therein.

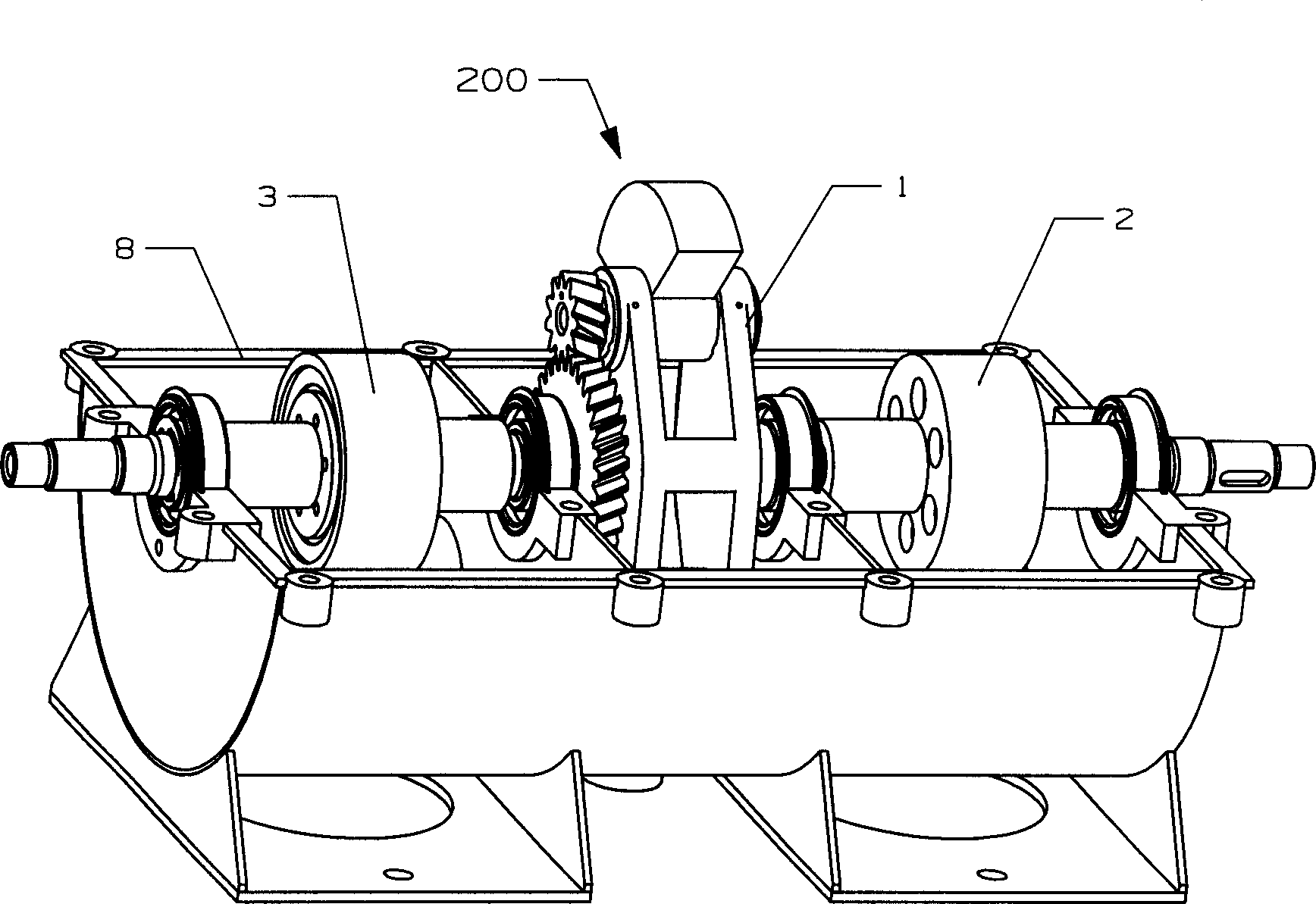

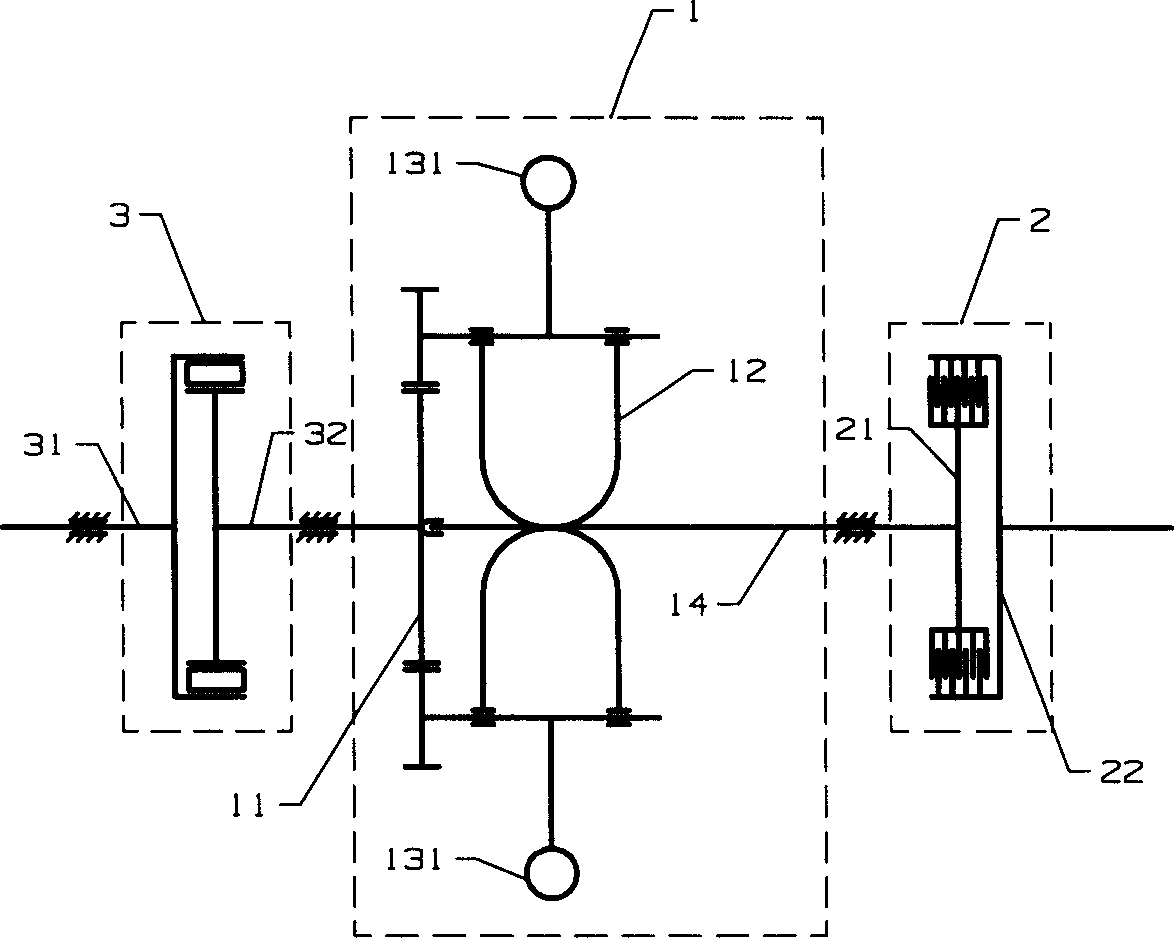

[0069] See Figure 1B According to the present invention, the mechanical continuously variable automatic transmission device 200 includes a housing 8 and a torque converter 1, a first one-way clutch 2 and a second one-way clutch 3 installed in the housing 8, Such as figure 2 As shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com