Process for producing gold surface pattern conductive polyphenylamine film

A conductive polyaniline, surface pattern technology, applied in electrolytic coatings, electrophoretic plating, electrolytic organic material plating, etc., can solve problems such as expensive equipment and damage to polymer layers, and achieve simple preparation methods, clear boundaries, and easy product composition. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

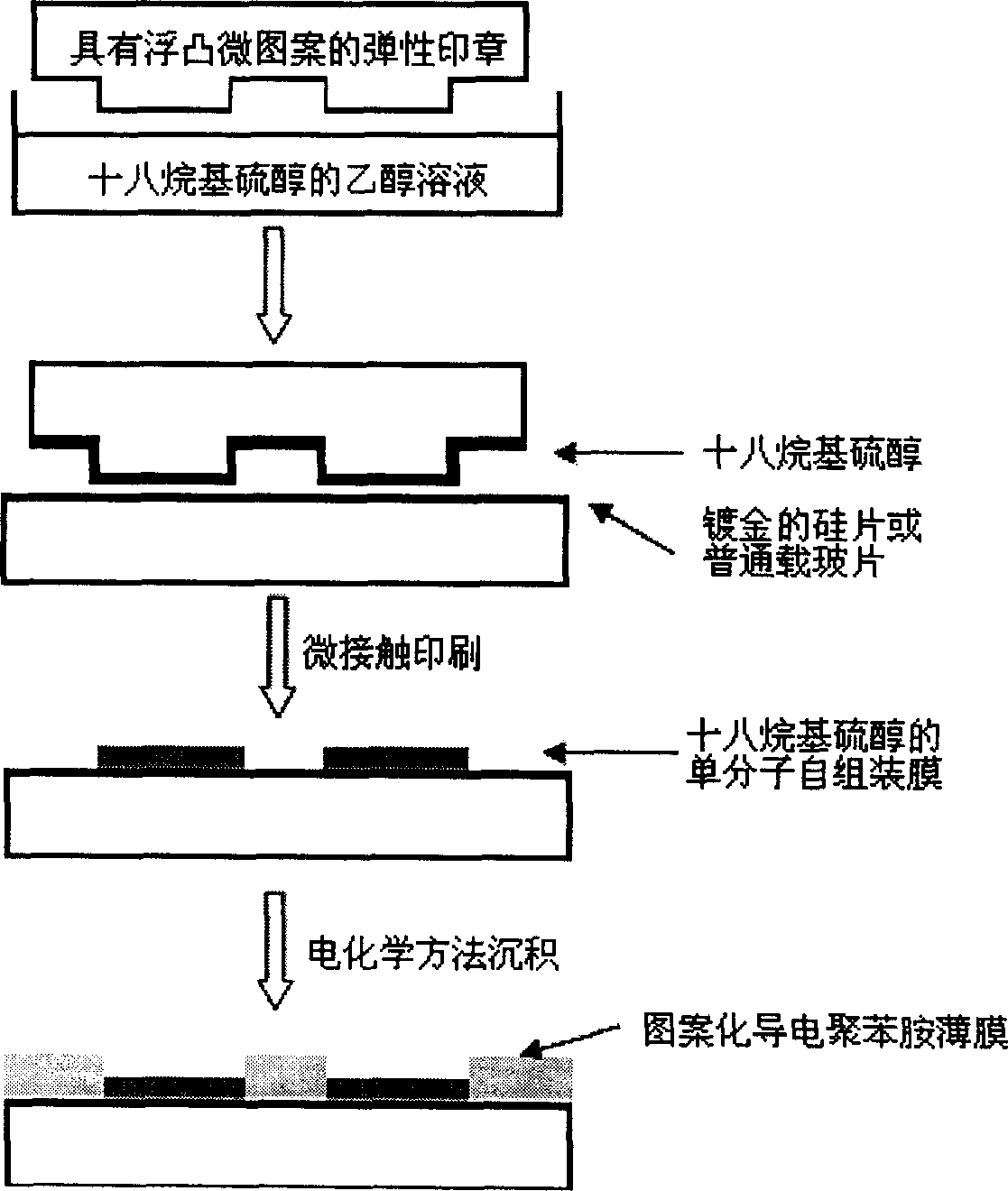

[0019] Fabrication of patterned polyaniline films on gold substrates:

[0020] 1. Preparation of Gold Substrate

[0021] The silicon substrate treated with the Piranha solution at 90° C. for half an hour was used to obtain a gold-plated substrate by vacuum thermal evaporation.

[0022] 2. Preparation of Patterned Elastic Stamps

[0023] Sylgard184 (Dow Corning Company) was coated on a micro-processed single-crystal silicon membrane plate, and then left to stand for 2 hours, cured at 150° C. for one hour, and an elastic stamp with micropatterns could be obtained after aging and peeling off.

[0024] 3. Fabrication of Patterned Self-Assembled Films

[0025] (1) A gold-plated silicon wafer was used as a substrate, and treated with a mixed solution (Piranha solution) of concentrated sulfuric acid and hydrogen peroxide with a volume ratio of 70%: 30% at 90° C. for 10 minutes.

[0026] (2) Prepare 2×10 -3 1 mole of octadecylmercaptan in absolute ethanol;

[0027] (3) immerse th...

Embodiment 2

[0033] Fabrication of patterned polyaniline films on gold-coated glass slide substrates:

[0034] 1. Preparation of Gold Substrate

[0035] The silicon substrate treated with the Piranha solution at 90° C. for half an hour was used to obtain a gold-plated substrate by vacuum thermal evaporation.

[0036] 2. Preparation of Patterned Elastic Stamps

[0037] The method is the same as above, peeled off after curing at 65°C for 90 minutes.

[0038] 3. Fabrication of Patterned Self-Assembled Films

[0039] (1) Using a patterned gold-plated glass slide as a working electrode, treat it with a mixed solution (Piranha solution) of concentrated sulfuric acid and hydrogen peroxide (Piranha solution) with a volume ratio of 70%: 30% at 85 ° C for 1 hour;

[0040] (2) Prepare 1×10 -3 1 mole of octadecylmercaptan in absolute ethanol;

[0041] (3) immerse the cleaned stamp in the prepared dilute mercaptan solution for 5 seconds, and dry it with nitrogen;

[0042] (4) Imprint the stamp ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com