Hydrogenation dearomatization catalyst containing molecular screen

A hydrogenation dearomatization and catalyst technology, applied in the direction of aromatics hydrogenation refining, etc., can solve the problems of linear decrease of catalyst specific surface area, pore blockage, carrier erosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

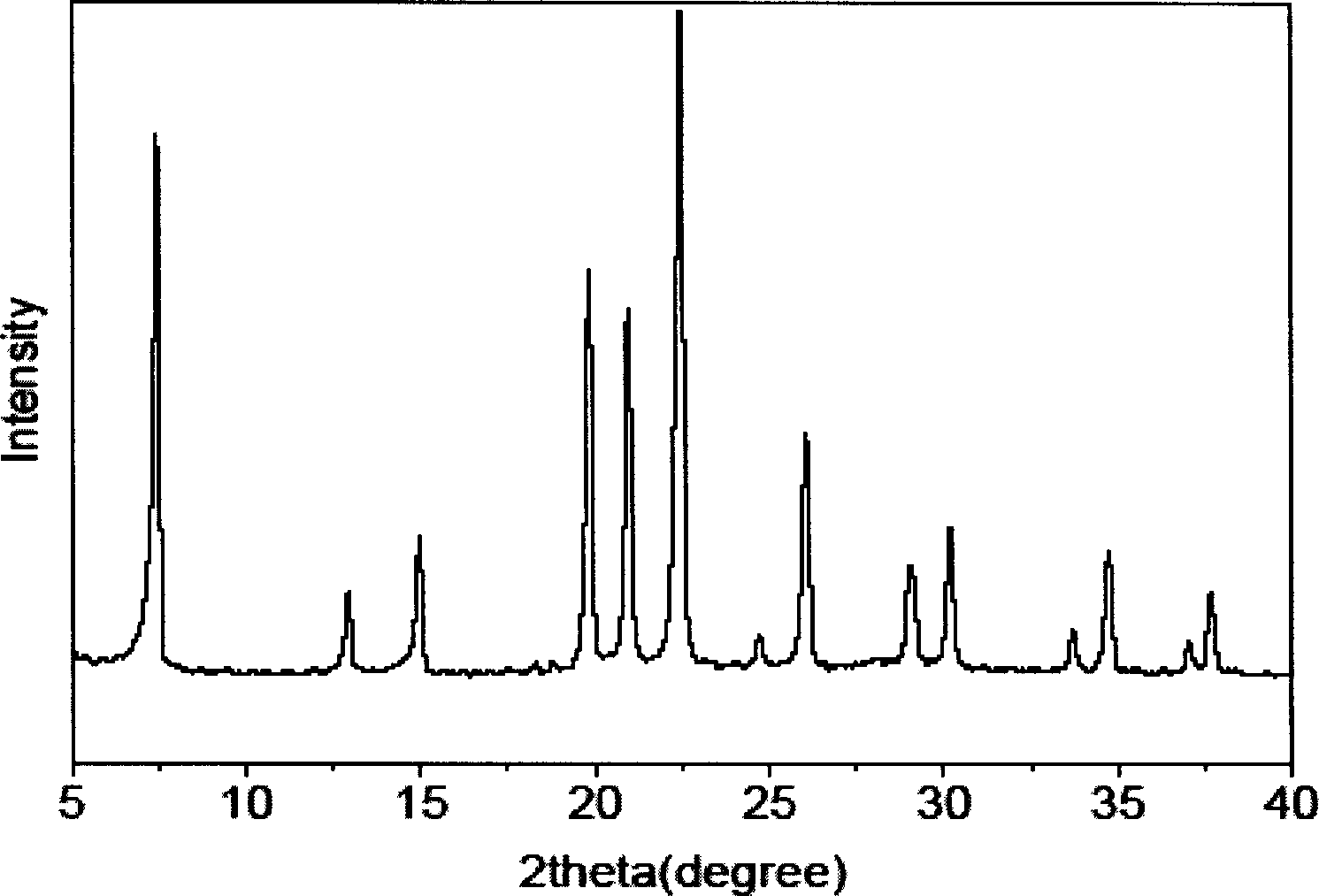

[0037] Synthesize 47 grams of AlPO, dried at 100℃ 4 -5 phosphate aluminum molecular sieve (see the XRD spectrum Figure one ), with 33 grams of pseudoboehmite powder produced by Shandong Aluminum Co., Ltd. and 10 grams of Sesbania powder. After mixing, add dropwise a mixed solution of 10 grams of concentrated nitric acid, 10 grams of citric acid and 50 grams of water. Into a 1mm cylindrical shape, dried at 100°C, and calcined at 550°C for 5 hours. Then it was immersed in a solution of 20 grams of nickel nitrate and 44 grams of ammonium metatungstate dissolved in 50 grams of water for 4 hours, dried at 100°C, and calcined at 550°C for 5 hours. According to specific requirements, it can be crushed or cut to the required particle size or length, and hydrogenation reaction can be carried out after vulcanization.

Embodiment 2

[0039] Synthesize 47 grams of AlPO, dried at 100℃ 4 -5 phosphate aluminum molecular sieve, 33 grams of pseudobo diaspore powder produced by Shandong Aluminum Co., Ltd. (same as Example 1), 10 grams of Sesbania powder, after mixing, 10 grams of concentrated nitric acid and 10 grams of lemon The mixed solution of acid and 50 grams of water is extruded into a 1mm cylindrical shape, dried at 100°C, and calcined at 550°C for 5 hours. First immerse with 20 grams of nickel nitrate dissolved in 50 grams of water for 4 hours, dry at 100°C, and roast at 550°C for 5 hours, then immerse with 44 grams of ammonium metatungstate dissolved in 50 grams of water for 4 hours, dry at 100°C, and roast at 550°C for 5 hours Rear. According to specific requirements, it can be crushed or cut to the required particle size or length, and hydrogenation reaction can be carried out after vulcanization.

Embodiment 3

[0041] The 47 grams of aluminum phosphate molecular sieve AlPO in Example 1 4 -5, replaced by 47 grams of 3.0% titanium (with TiO 2 Total, mass percentage) of heteroatom AlPO 4 -5, the following preparation is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com