Non-porous single dispersed polymer weak cation exchange resin, its preparation method and use

A weak cation exchange and monodisperse technology, which is applied in the field of non-porous monodisperse polymer weak cation exchange resin and its preparation and application, can solve the problems of difficult chemical modification, etc., and achieve easy scale-up of equipment, increase of separation and analysis speed, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

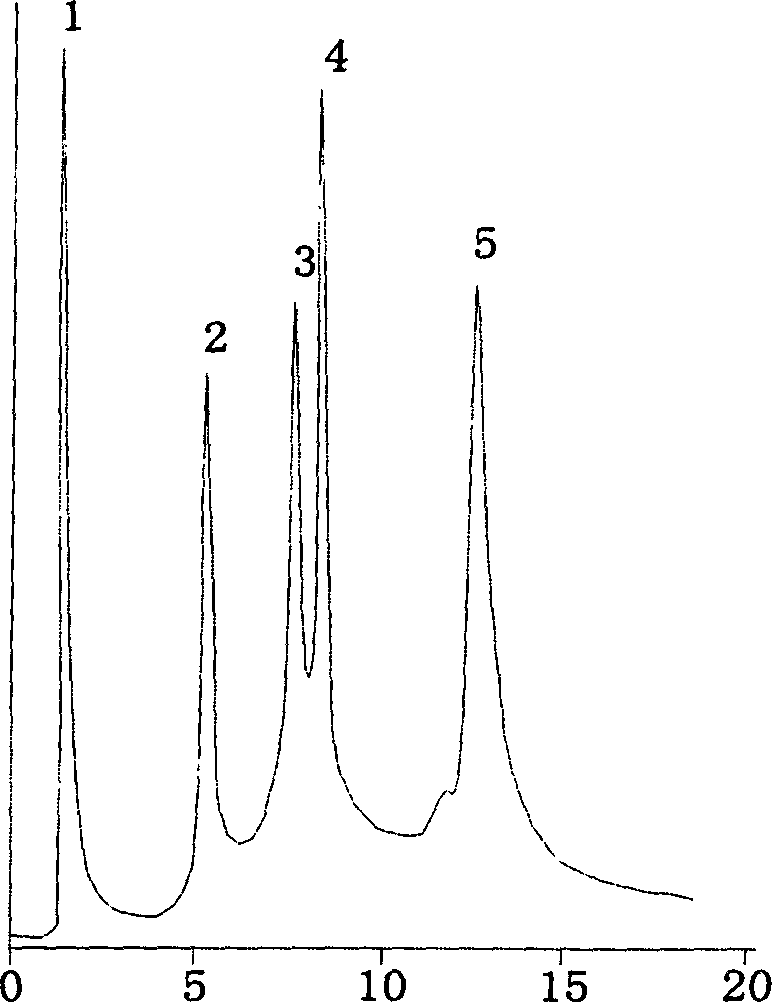

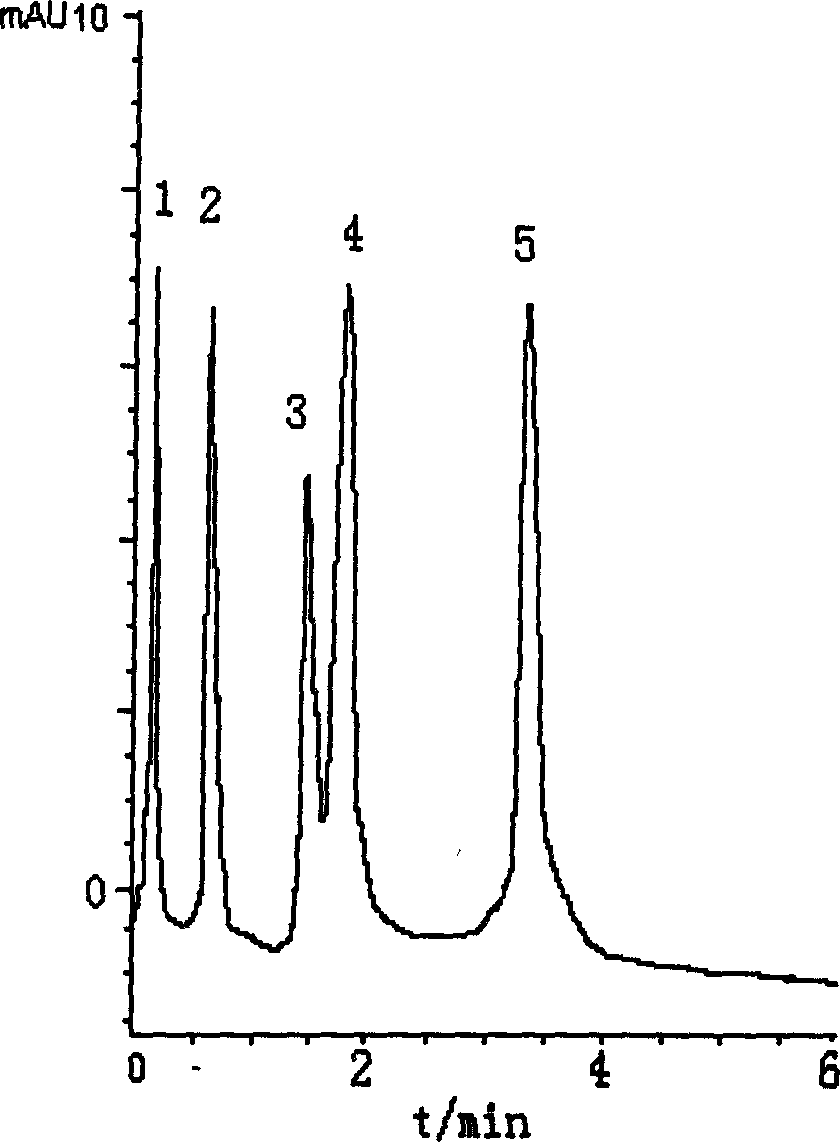

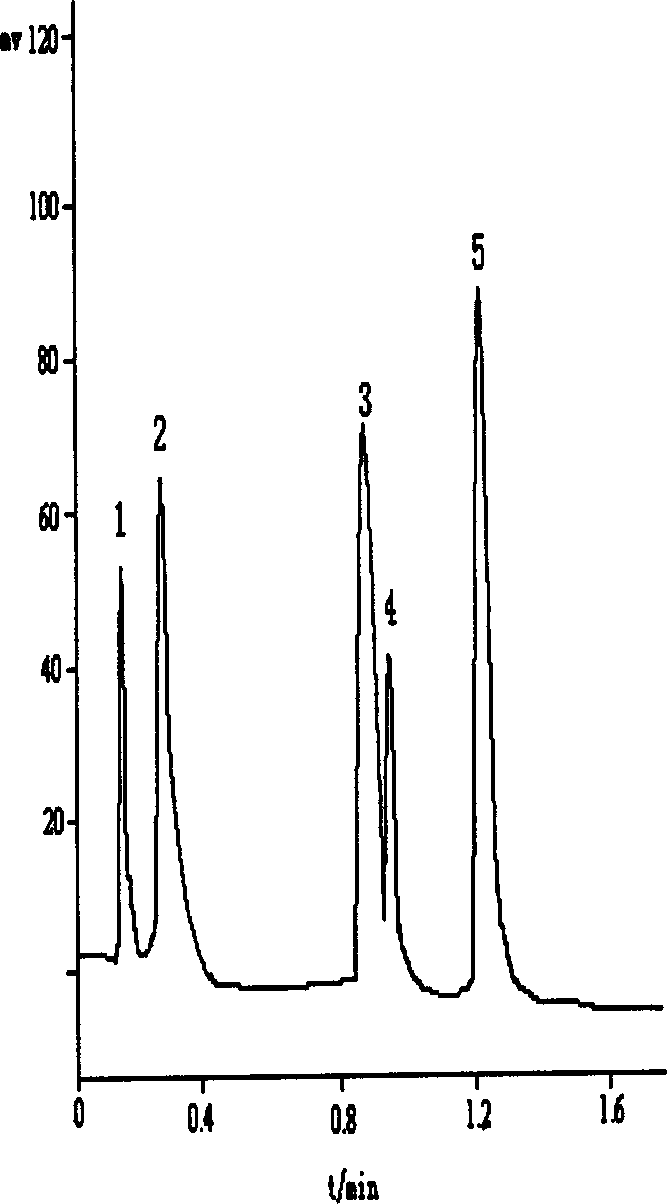

[0035] Example 1: The preparation method of 7.0 μm non-porous monodisperse weak cation exchange resin is carried out in the following order:

[0036] 1) Preparation of 3.0 μm monodisperse linear low molecular weight polystyrene seeds:

[0037]Add 20mL St, 0.4g AIBN, 1.0g PVP and 80mL absolute ethanol to a 100mL round-bottomed flask, ultrasonically dissolve, blow nitrogen to remove oxygen, stir and heat in a constant temperature water bath at 70°C, and react for 24 hours. Remove the solvent, wash several times with absolute ethanol, transfer to a conical flask with 0.2% SDS solution for later use, take a small amount and observe its shape and size under a microscope. The product is monodisperse polystyrene microspheres with a particle size of 3.0 μm.

[0038] 2) Preparation of 7.0 μm non-porous monodisperse hydrophilic cross-linked polyglycidyl methacrylate microspheres:

[0039] Accurately transfer 6mL GMA, 6mL EDMA, and 0.27g BPO into a 250mL beaker. After the BPO is dissolv...

Embodiment 2

[0043] Embodiment 2: The preparation method of 5.0 μm non-porous monodisperse weak cation exchange resin is carried out in the following order:

[0044] 1) Preparation of 2.2 μm monodisperse linear low molecular weight polystyrene seeds

[0045] Add 10mL St, 0.2g AIBN, 0.5g PVP and 90mL absolute ethanol to a 100mL round-bottomed flask, ultrasonically dissolve, blow nitrogen to remove oxygen, stir and heat in a constant temperature water bath at 70°C, and react for 24 hours. Remove the solvent, wash several times with absolute ethanol, transfer to a conical flask with 0.2% SDS solution for later use, take a small amount and observe its shape and size under a microscope. The product is monodisperse polystyrene microspheres with a particle size of 2.2 μm.

[0046] 2) Preparation of 5.0 μm non-porous monodisperse hydrophilic cross-linked polyglycidyl methacrylate microspheres

[0047] Accurately transfer 4.5mL GMA, 4.5mL EDMA, 0.18g BPO into a 250mL beaker, after the BPO dissolv...

Embodiment 3

[0051] Example 3: The preparation method of 3.0 μm non-porous monodisperse weak cation exchange resin is carried out in the following order:

[0052] 1) Preparation of 0.6 μm monodisperse linear polystyrene seeds:

[0053] Add 12.0mL St, 0.24g AIBN, 1.5g PVP and 135mL 90% ethanol solution into a 100mL round bottom flask, ultrasonically dissolve, blow nitrogen to remove oxygen, stir and heat in a constant temperature water bath at 70°C, and react for 24 hours. Remove the solvent, wash several times with absolute ethanol, transfer to a conical flask with 0.1% SDS solution for later use, take a small amount and observe its shape and size under a microscope. The product is monodisperse polystyrene microspheres with a particle size of 0.6 μm.

[0054] 2) Preparation of 3 μm non-porous monodisperse hydrophilic cross-linked polyglycidyl methacrylate microspheres:

[0055] Accurately add 1.0 g of 0.6 μm monodisperse polystyrene seeds synthesized in the previous step and 20 mL of 0.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com