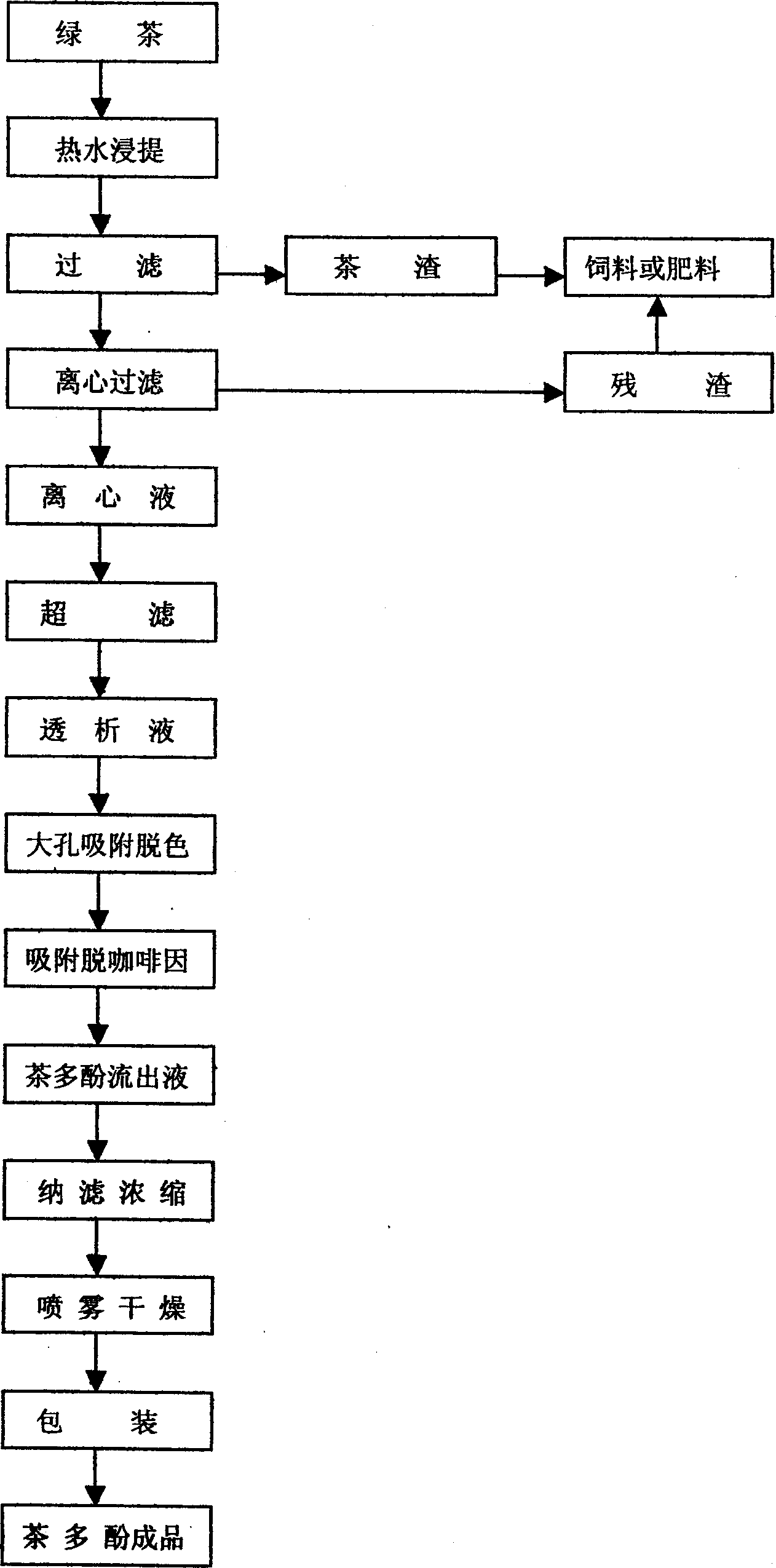

Method of preparing tea polyphenol by resin adsorption method

A technology of resin adsorption and tea polyphenols, applied in the direction of organic chemistry, can solve the problems of large investment in disposable equipment and unfavorable industrialization promotion, and achieve the effects of improving quality and safety, avoiding organic solvent residues, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. Extraction

[0044] (1) Selection of raw materials

[0045] The main raw material for the production of tea polyphenols is green tea or green tea powder. %) and hygienic indicators (pesticide residue ≤ 10mg / Kg, heavy metal ≤ 20mg / Kg) to strictly control the quality of raw materials. In particular, it is necessary to strictly control the pesticide residues and heavy metal content in the health indicators. If one of the indicators is unqualified, it cannot be used as a raw material for production.

[0046] (2), leaching coarse filtration

[0047] Put 200kg of green tea into the extraction equipment with heating and stirring device (3000L multifunctional extraction tank), add 2400L of pure water for the first time, close the feeding port, start stirring, open the steam valve, heat to 75-85°C, Stir (rotating speed 20r / min) to extract for 40min, perform second extraction after filtration. For the second extraction, add 1600L of pure water, heat to 75°C, stir and extra...

Embodiment 2

[0063] 1. Extraction

[0064] 1) The selection of raw materials is the same as in Example 1.

[0065] 2), leaching coarse filtration

[0066] Put 200kg of green tea into the extraction equipment with heating and stirring device (3000L multifunctional extraction tank), add 2300L of pure water for the first time, close the feeding port, start stirring, open the steam valve, and heat to 75-85°C , stirring (rotating speed 20r / min) to extract for 40min, after filtering, carry out the second extraction. For the second extraction, add 1700L of pure water, heat to 75°C, stir and extract for 40min, and filter. The filtrate was cooled to 35°C by heat exchange twice, and put into a 4000L extract storage tank (measured solid content=1.34%).

[0067] 2. Centrifugal filtration

[0068] The extract is pumped into a centrifuge at a flow rate of 35L / min at normal temperature and pressure, and continuously centrifuged at 6000r / min to obtain a clarified green tea extract, which is then put i...

Embodiment 3

[0081] Extraction, filtration, polar macroporous resin adsorption decolorization, ultra-high cross-linked adsorption resin decaffeination, nanofiltration concentration, spray drying and packaging in this example are the same as in Examples 1 and 2, except that step 3) The ultrafiltration is to pump the centrifugal green tea clarified liquid into the tubular ultrafiltration equipment at a flow rate of 37L / min for ultrafiltration to remove tea polysaccharides, pectin and other impurities, and the ultrafiltrate is put into a 4000L storage tank. The selected tubular ultrafiltration membrane is a composite membrane with a molecular weight cut off of 20,000. The ultrafiltration process conditions are: room temperature, inlet pressure 6.5bar, outlet pressure 1.5bar. The outlet flow rate of the ultrafiltrate was 26 L / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com