Method for enhancing metal-medium-metal structural capacity performance

A metal structure and metal technology, applied in the field of multi-layer metal plates, can solve the problems of quality factor Q value reduction, increase chip area, and reduce the quality of dielectric layers, etc., to achieve quality factor Q value improvement, simple process method, and optimization The effect of surface condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

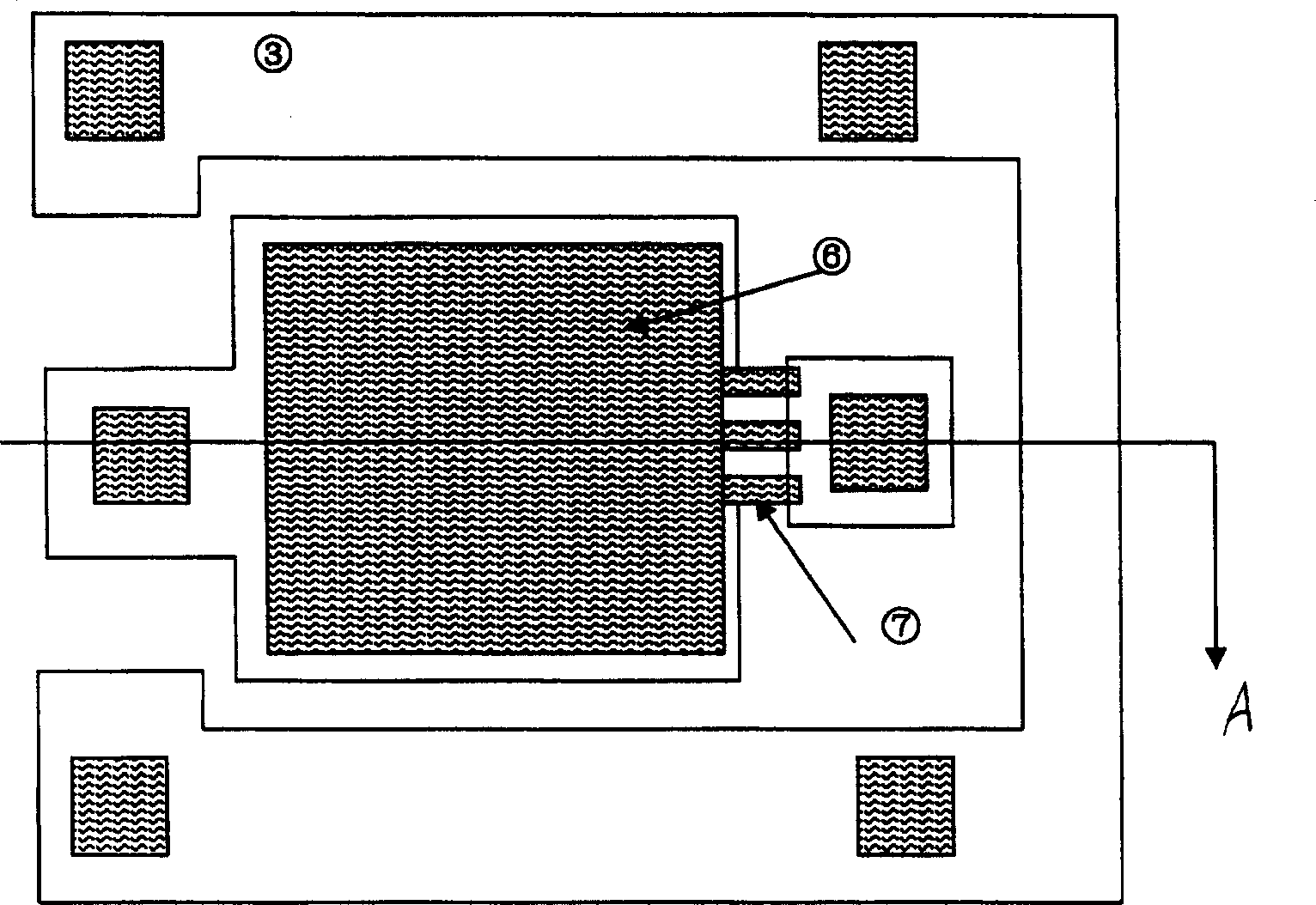

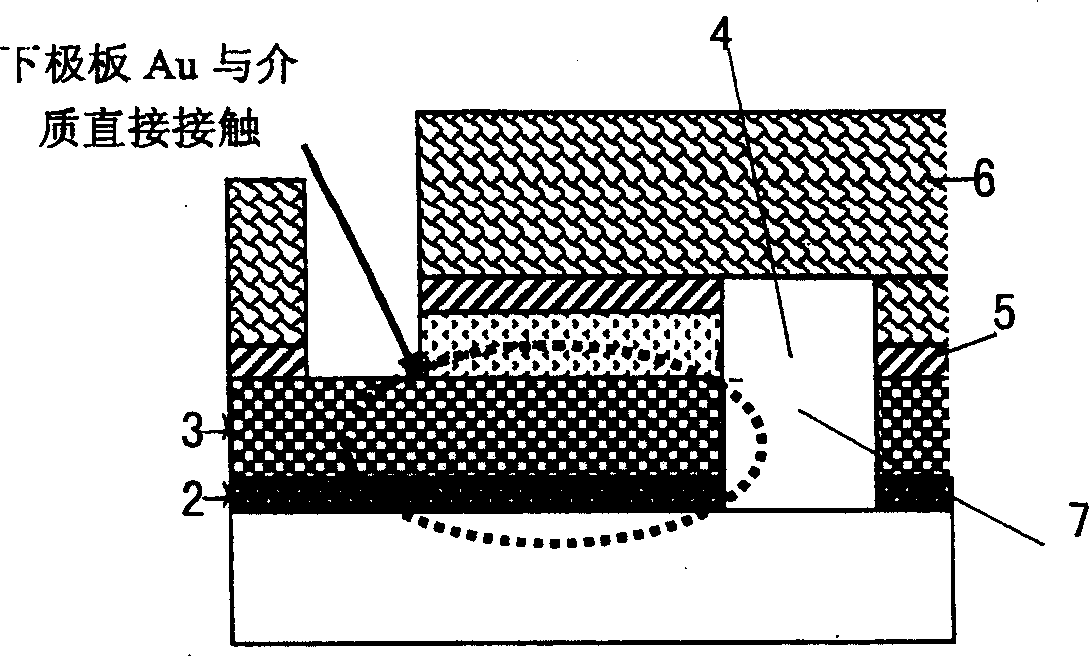

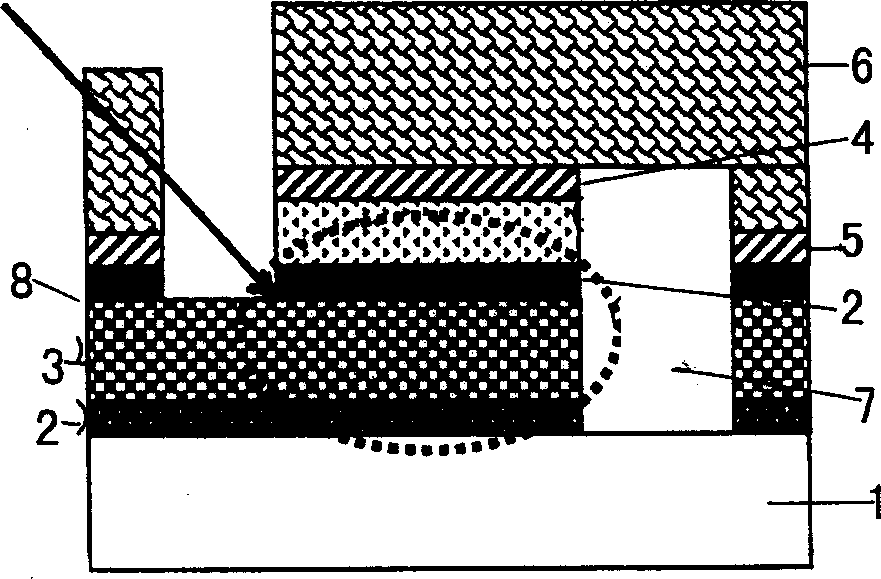

[0037] please see figure 1 , image 3 , Figure 10 . figure 1 It is a schematic top view of the metal-dielectric-metal capacitor of the present invention, image 3 for figure 1 A sectional view of the metal-dielectric-metal capacitor of the present invention in direction A, Figure 10 It is a process flow chart of the metal-dielectric-metal capacitor of the present invention. Depend on image 3 As shown, the structure of the metal-dielectric-metal capacitor of the present invention is: on the surface of the substrate 1, the titanium layer 2, the gold layer 8, and the titanium layer 2 are fixed in sequence, and the three layers constitute the lower plate 3. The dielectric layer 4 is affixed to the titanium layer 2 on the upper surface of the central area of the lower plate 3, and the plating layer 5 is affixed to the upper surface of the peripheral area of the dielectric layer 4 and the middle gold layer 8, and the upper surface of the plating layer 5 is affixed to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com