Sulfuric-acid residue sorting and refinement method

A purification method and technology of sulfuric acid slag, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve problems such as low sorting efficiency, complicated process flow, and difficult process control, so as to achieve no secondary pollution, The effect of simple process flow and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

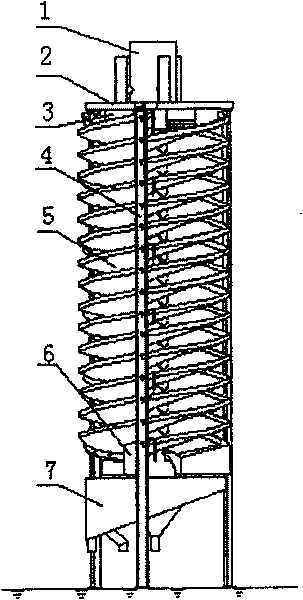

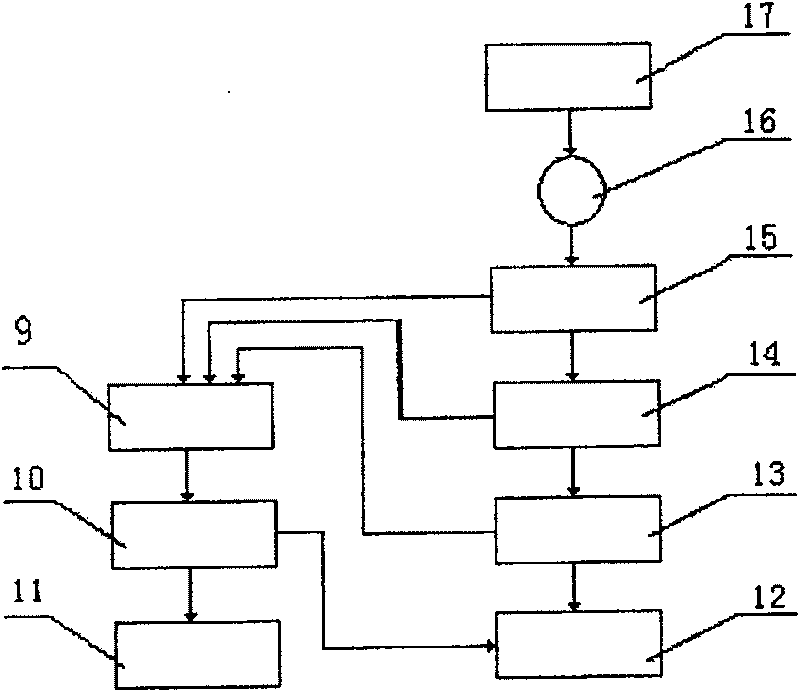

[0022] A kind of sulfuric acid slag sorting purification method such as image 3 As shown, the original sulfuric acid slag [17] with TFe≥45%, S<3%, and particle size of -0.074mm accounting for 55-85% is made into slurry with a concentration of 20-30% through the stirring tank [16], and sent into Sulfuric acid slag separation, purification and sorting equipment [15] performs roughing, and the rough-selected concentrate is directly sent to the sulfuric acid slag separation, purification and sorting equipment [14] for the first selection, and the concentrate obtained from the first selection is sent to Sulfuric acid slag separation, purification and sorting equipment [13] carries out the second selection.

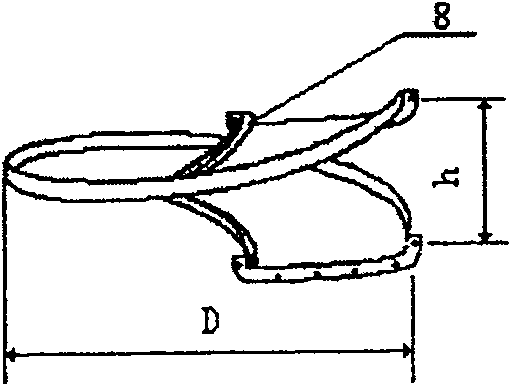

[0023] The equipment [15], [14], [13] used for roughing and refining is a single type, and the application number is CN200410060867.2 "a kind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com