Method of separation/purification for high-purity silver chloride and process for producing high-purity silver by the same

A refining method, silver chloride technology, applied in chemical instruments and methods, silver halides, silver compounds, etc., can solve the problems that cannot be extracted and separated by solution, and achieve the effect of great industrial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] Using the above-mentioned chlorine leaching residue as a raw material, a series of processes of leaching, chloride generation and chloride purification in the separation and purification method of high-purity silver chloride of the present invention are carried out, and each process is obtained by the production method of high-purity silver of the present invention. The product is reduced to metallic silver, and the silver powder is analyzed.

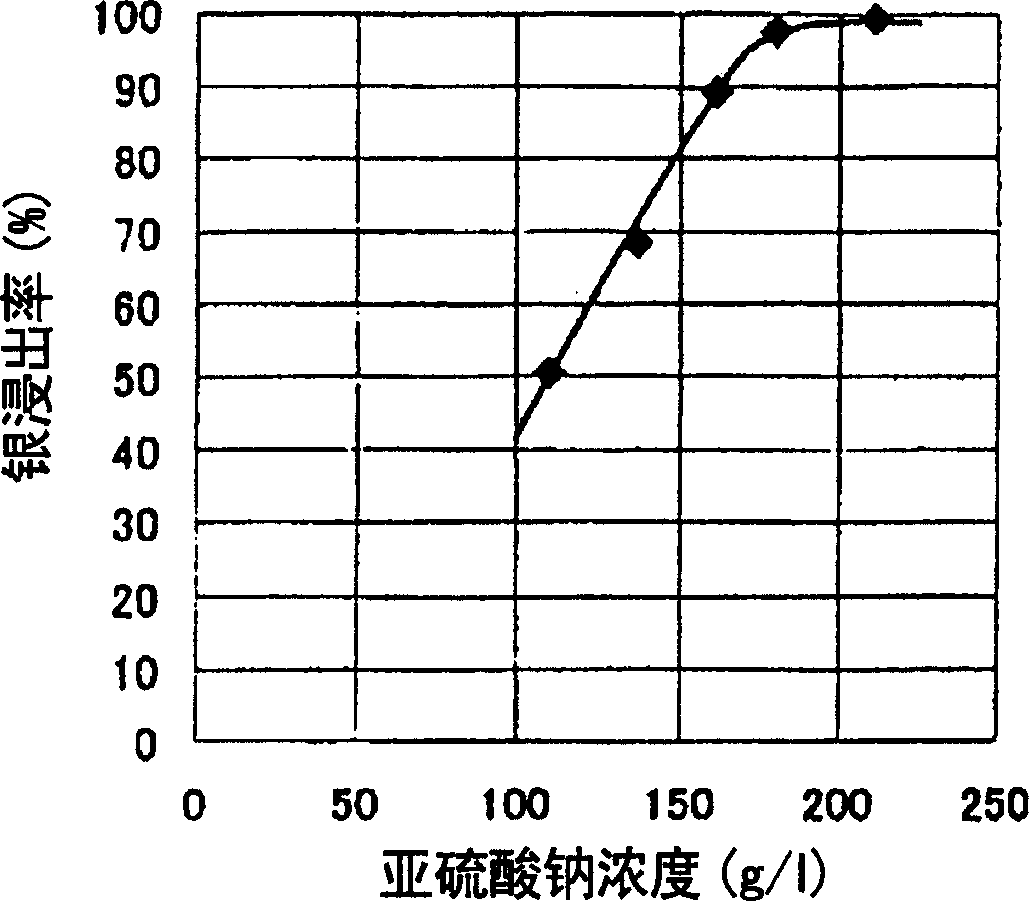

[0103] (1) Leaching process

[0104] The solution prepared from sodium sulfite reagent and the absorption solution obtained by absorbing sulfur dioxide gas generated in the smelting process of metal smelting into sodium hydroxide aqueous solution are used for leaching as an aqueous sulfite solution.

[0105] When using a solution prepared from sodium sulfite reagent as the aqueous sulfite solution, suspend 45 g of chlorine leaching residue (wet weight) in 400 mL of water, dissolve 100 g of anhydrous sodium sulfate into the slurry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| reduction potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com