Composite collagen nerve ductus for promoting neural regeneration, and method for forming filature from hollow wet process

A technology of nerve conduit and wet spinning, which is applied in the direction of biochemical equipment and methods, catheter, filament/thread forming, etc., to achieve the effect of avoiding loss and promoting repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

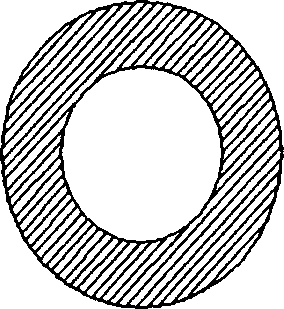

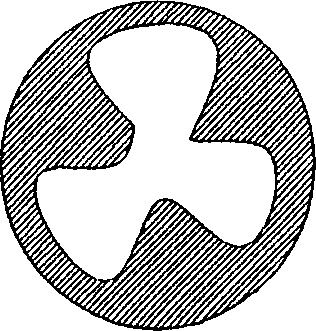

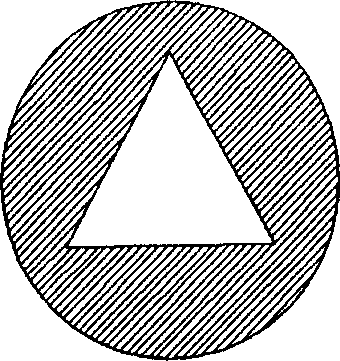

Image

Examples

Embodiment 1

[0029] The preparation of embodiment 1 composite bovine collagen spinning stock solution

[0030] Cut the bovine Achilles tendon, wash, remove the aponeurosis, quick-freeze, slice, then cool and wash, treat with 0.8% dimethyl sulfoxide alkali solution for 58 hours to degrease, and then mash it with a high-speed tissue grinder with a rotation speed of 12000r / min crushed, centrifuged (4000r / min) for 15min, and removed the supernatant. Add NaCl (2.0M) to soak for 5min, stir evenly, add Tris-HCl (0.05M, pH=7.5) to soak for 30min, stir overnight, centrifuge (4000r / min) for 20min, repeat NaCl / Tris-HCl treatment several times until the supernatant Liquid viscosity is extremely low. Rinse briefly and repeatedly with cold distilled water until NaCl is removed, centrifuge (4000r / min) for 5min, and dry in the air. Add 0.1% pepsin (model 1:3000) with a weight ratio of 8:1, tetrasodium EDTA and 20 times the volume of distilled water, and place it in an incubator at about 37°C for 24 hour...

Embodiment 2

[0033] The preparation of embodiment 2 composite bovine collagen spinning dope

[0034] Cut the beef Achilles tendon, wash, remove the aponeurosis, quick-freeze, slice, then cool and wash, treat with 2% dimethyl sulfoxide alkali solution for 24 hours to degrease, and then mash with a high-speed tissue grinder with a rotation speed of 12000r / min crushed, centrifuged (4000r / min) for 20min, and removed the supernatant. Add NaCl (3.0M) to soak for 5min, stir evenly, add Tris-HCl (0.05M, pH=7.5) to soak for 30min, stir overnight, centrifuge (4000r / min) for 20min, repeat NaCl / Tris-HCl treatment several times until the supernatant Liquid viscosity is extremely low. Rinse briefly and repeatedly with cold distilled water until NaCl is removed, centrifuge (4000r / min) for 5min, and dry in the air. Add 0.4% pepsin (model 1:3000) with a weight ratio of 4:1, tetrasodium EDTA EDTA and 10 times the volume of distilled water, and place it in an incubator at about 37°C for 24 hours to make th...

Embodiment 3

[0037] The preparation of embodiment 3 composite bovine collagen spinning dope

[0038] Cut the beef Achilles tendon, wash, remove the fascia, quick-freeze, slice, then cool and wash, treat with 5% dimethyl sulfoxide alkali solution for 72 hours to degrease, and then mash with a high-speed tissue grinder with a speed of 12000r / min , centrifuge (4000r / min) for 30min, and remove the supernatant. Add NaCl (4.0M) to soak for 5min, stir evenly, add Tris-HCl (0.05M, pH=7.5) to soak for 30min, stir overnight, centrifuge (4000r / min) for 20min, repeat NaCl / Tris-HCl treatment several times until the supernatant Liquid viscosity is extremely low. Rinse briefly and repeatedly with cold distilled water until NaCl is removed, centrifuge (4000r / min) for 5min, and dry in the air. Add 0.3% pepsin (model 1:3000) with a weight ratio of 6:1, tetrasodium EDTA EDTA and 10 times the volume of distilled water, and place it in an incubator at about 37°C for 24 hours to make the collagen After enzym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com