High-efficiency environment-friendly acid-mixed plating removal liquor

A technology of stripping solution and mixing acid, which is applied in the field of efficient and environmentally friendly utilization of high-acid stripping solution, can solve the problems of inability to achieve environmental protection, secondary pollution, pollution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below by means of the accompanying drawings and examples.

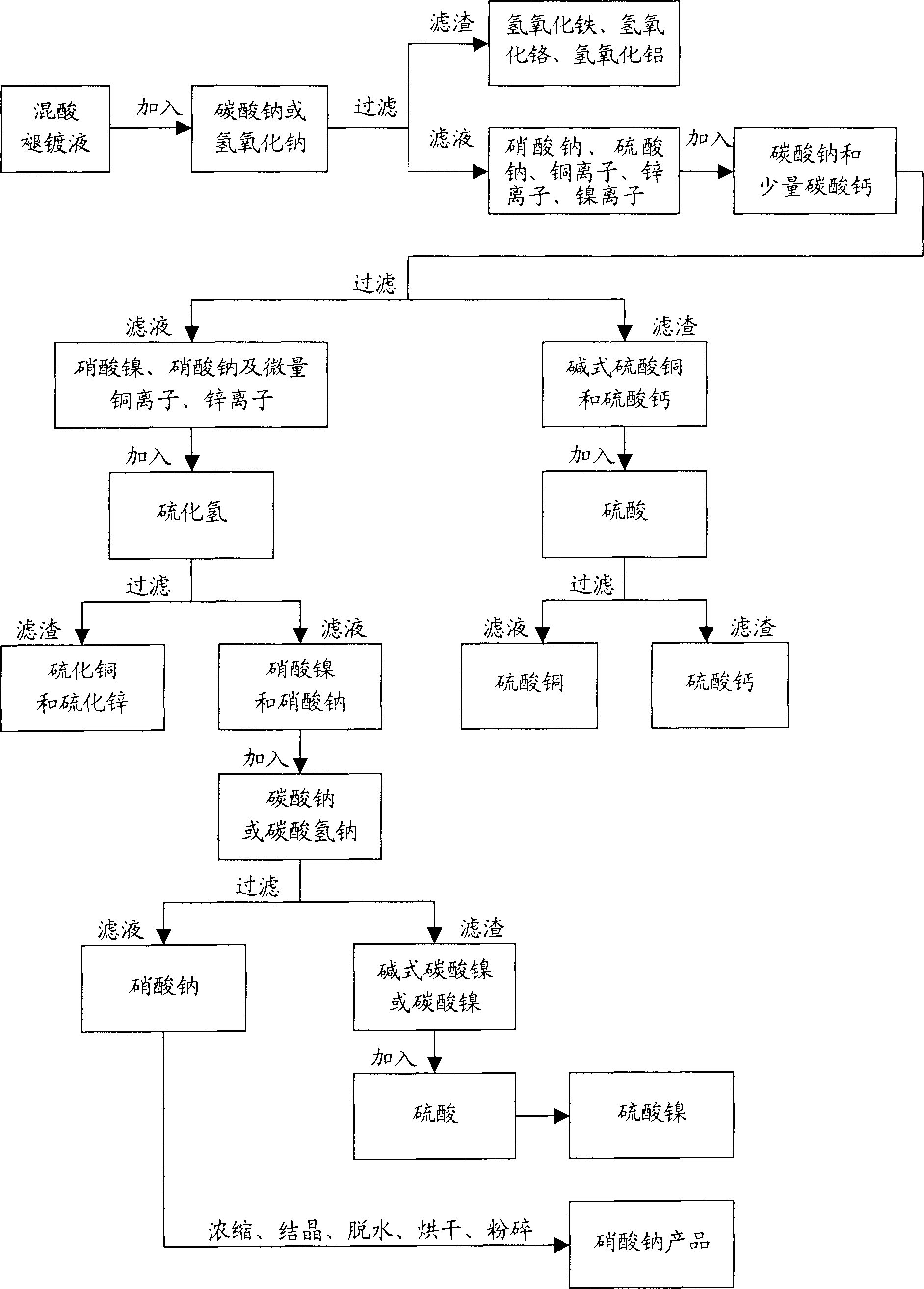

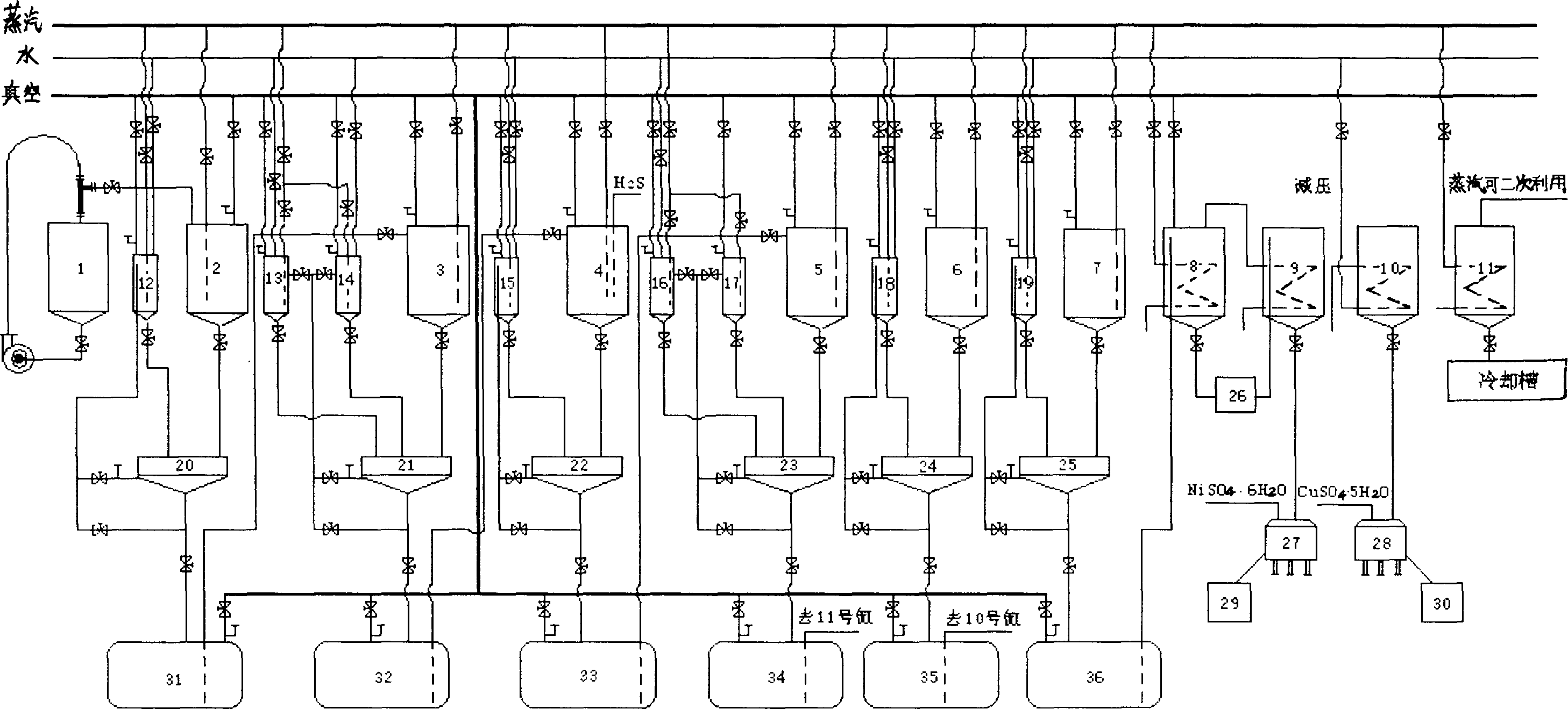

[0024] Such as figure 1 As shown, the steps of an embodiment of an efficient and environment-friendly utilization method of a mixed acid stripping solution are as follows: the mixed acid stripping solution is put into a reaction kettle, firstly add sodium carbonate or sodium hydroxide to neutralize free nitric acid and sulfuric acid, trace iron, chromium , Aluminum and other impurities are hydrolyzed and precipitated by hydroxide, and the pH value is controlled throughout the reaction; Filtration, that is, filtering out iron hydroxide, chromium hydroxide, aluminum hydroxide filter residue, the main components in the filtrate are sodium nitrate, sodium sulfate, Copper ions, zinc ions, nickel ions, when the pH reaches 3.8-4, heat to 80-85°C, heat and stir for 1 hour, put the filtrate and a small amount of washing liquid into the sinking copper tank, heat t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com