Liquid-cooled heat sink

A heat dissipation device and liquid cooling technology, applied in cooling/ventilation/heating transformation, instrumentation, electrical digital data processing, etc., can solve problems such as heat absorption or external heat dissipation, limited heat dissipation speed, and increased cost, etc., to achieve Best heat dissipation effect, reduced production cost, and large heat storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

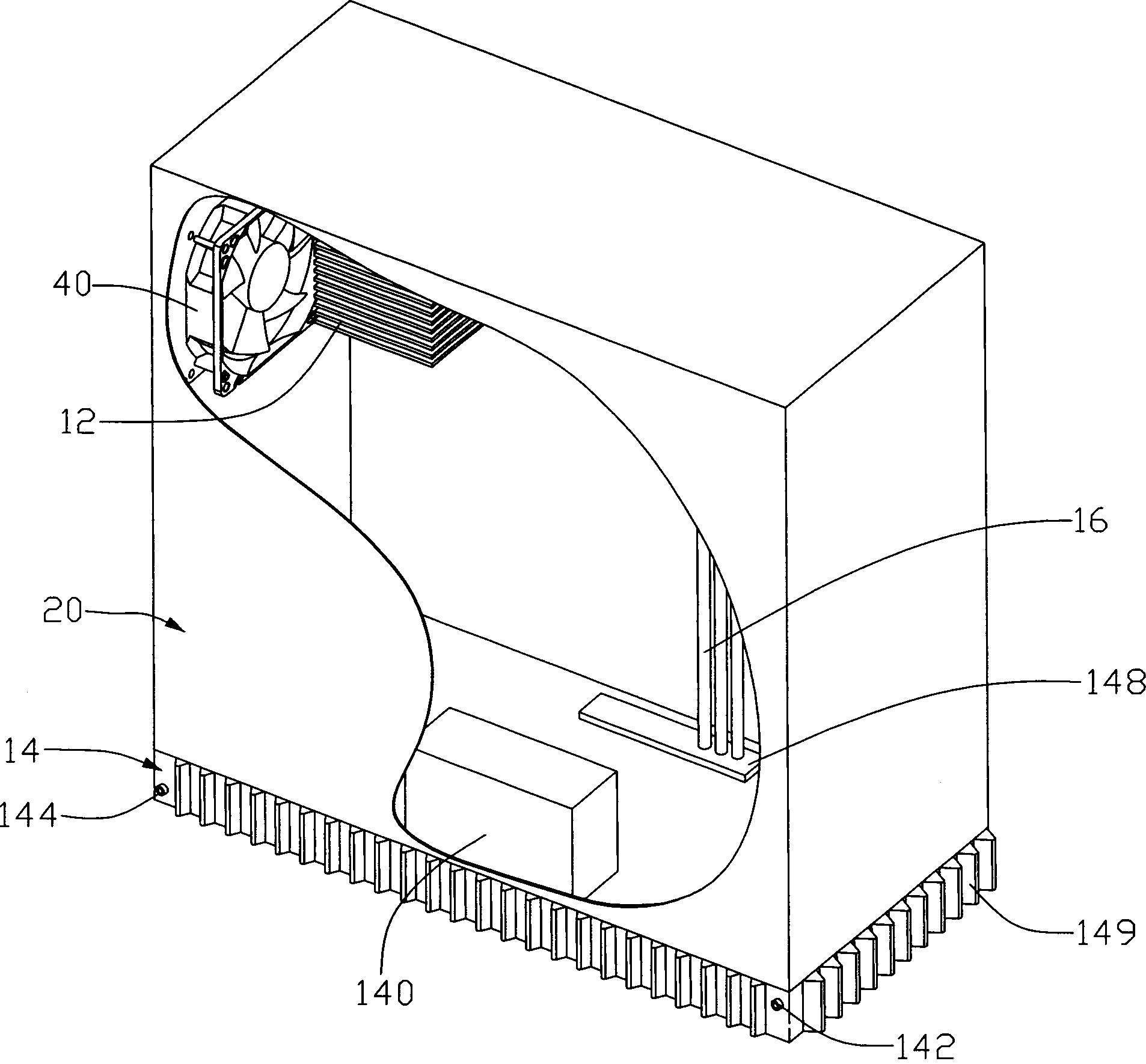

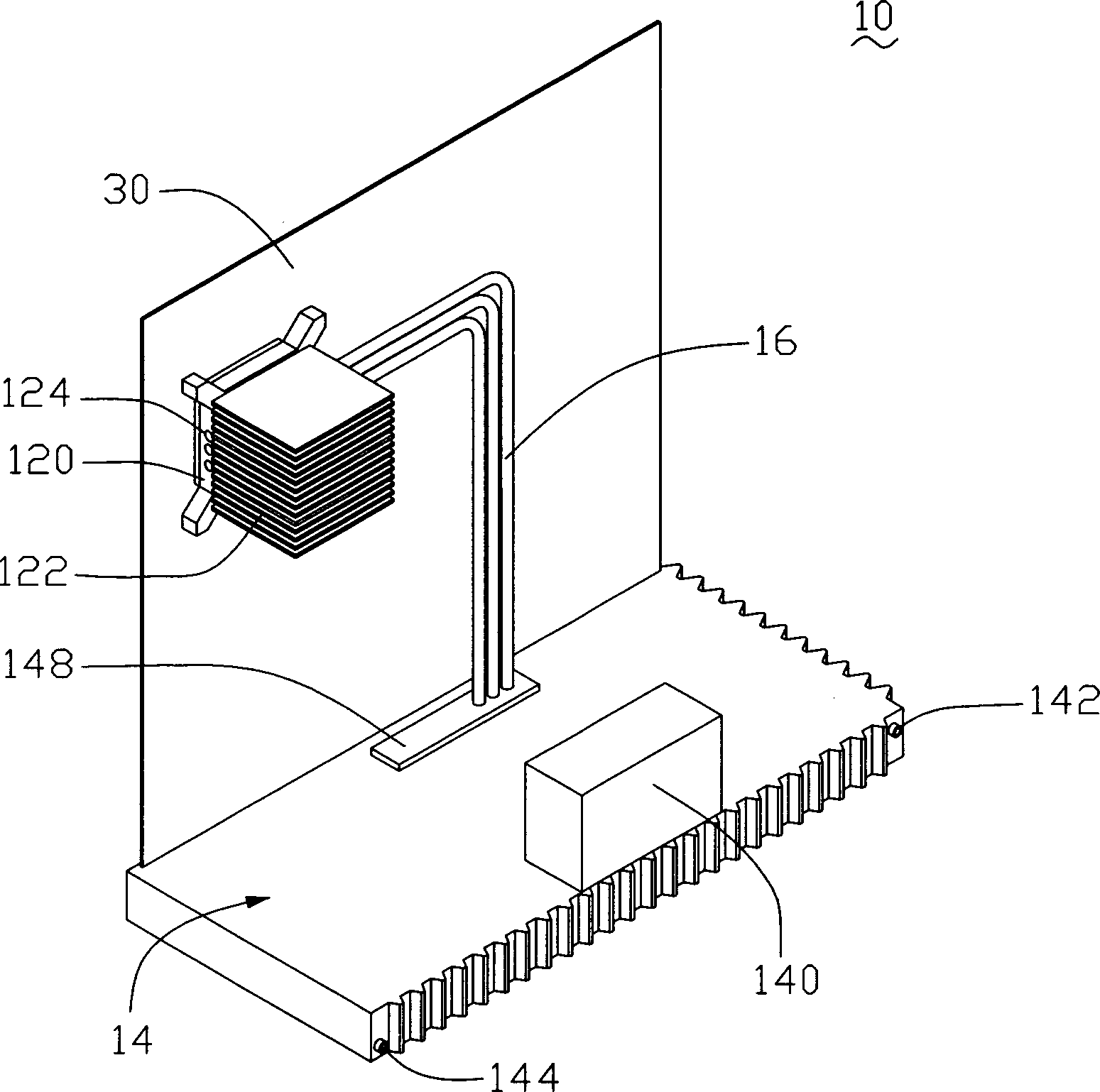

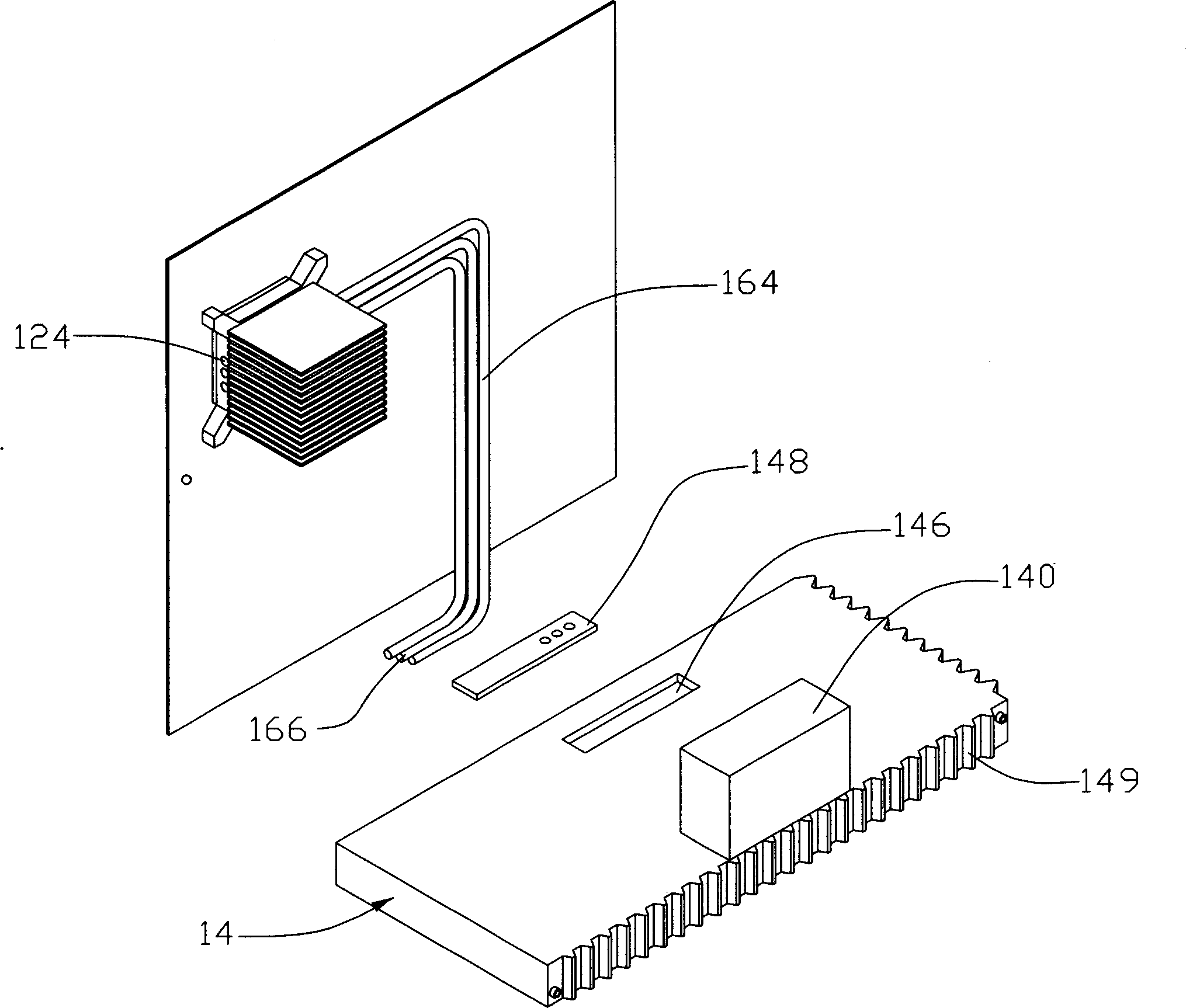

[0013] see Figure 1 to Figure 3 The liquid-cooled heat dissipation device 10 of the present invention includes a radiator 12 installed on electronic components (not shown) such as a central processing unit (not shown) in the cabinet 20 for cooling, and a radiator 12 that is independent of the radiator 12 and installed on an appropriate part of the cabinet 20. The liquid storage tank 14 and several heat pipes 16 connected to the radiator 12 and the water storage tank 14 by its two ends respectively.

[0014] Above-mentioned heat sink 12 comprises a base 120 that contacts on the electronic component and is fixed on the circuit board 30 and a plurality of cooling fins 122 that are arranged and formed on this base 120, and several grooves 124 are also provided on this base 120, for One end of the heat pipe 16 is thermally connected.

[0015] The liquid storage tank 14 is substantially a cuboid cavity, which has a larger volume to hold a large amount of liquid, such as water. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com