Biodegradable film having honeycomb structure

A honeycomb structure and biological technology, applied in medical science, surgery, coating, etc., to achieve the effects of easy handling, improved safety, and high biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

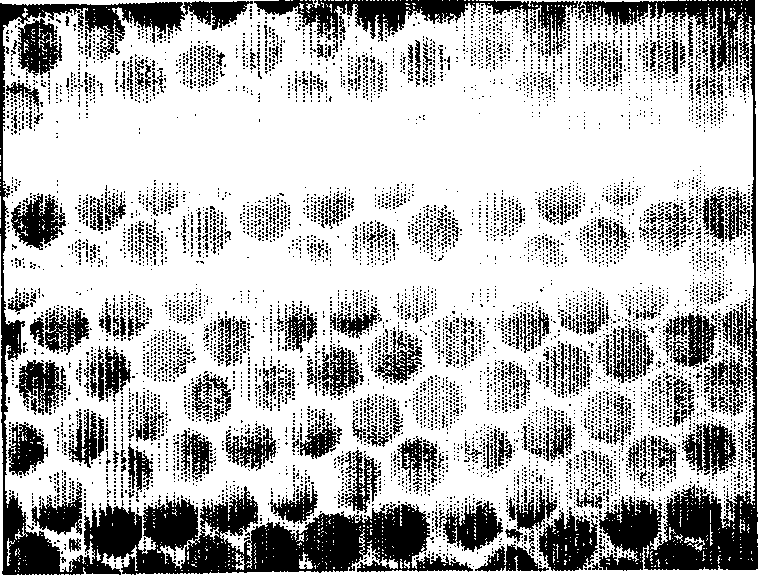

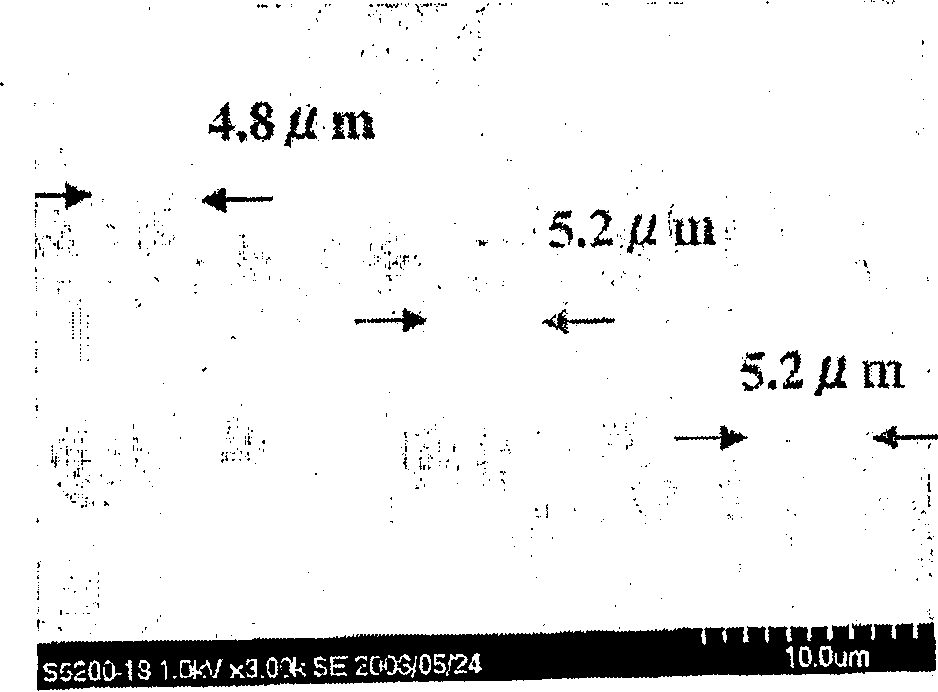

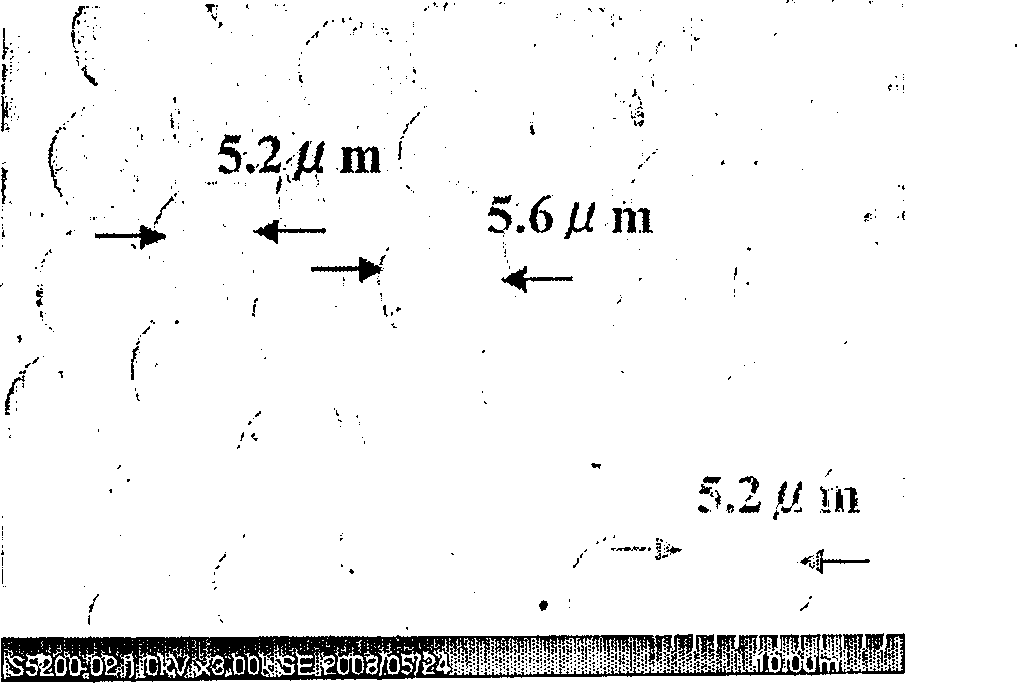

[0049] In the chloroform solution (5g / L) of polylactic acid (molecular weight 100000), mix the polyacrylamide copolymer (weight average molecular weight: 85,000) shown in compound formula 1 as amphiphilic polymer with the ratio of 10:1, in The honeycomb structure was prepared by casting on a glass substrate, leaving still at room temperature and a humidity of 70%, and slowly evaporating the solvent. The honeycomb structure of the thus obtained structure had a cell inner diameter of 5 μm and a film thickness of 13 μm. Optical microscope photographs such as figure 1 shown.

Embodiment 2

[0051] In a chloroform solution (5 g / L) of polylactic acid-polyglycolic acid copolymer (copolymer ratio 75:25, molecular weight 100,000), a polyacrylamide copolymer as an amphiphilic polymer was mixed in a ratio of 10:1, The honeycomb structure was prepared by casting on a glass substrate, leaving still at room temperature and a humidity of 70%, and slowly evaporating the solvent. The honeycomb structure of the thus obtained structure had a cell inner diameter of 5 μm and a film thickness of 13 μm.

[0052] The structural formula of the polyacrylamide copolymer used is shown below.

[0053]

[0054] (m, n represent repeating units, m:n=1:4.)

Embodiment 3

[0060] Male SPF hairless rats (average body weight 250g) were anesthetized by intraperitoneal injection, the abdomen was incised to expose the stomach, and then a wound of about 8 mm was made on the epidermis of the bottom wall of the stomach, and Examples 1, 2 and Comparative Example 1 were applied. , 2 The anti-adhesion materials (3cm square) obtained respectively, one for each rat. After applying the anti-adhesion material, a necropsy was performed one week later, and the adhesion state was observed with the naked eye. The adhesion state of each rat is shown in Table 1 below.

[0061] The honeycomb structure films of Examples 1 and 2 did not gel or dissolve when immersed in water, and since the films were soft, they were easy to stick to the affected area and had good handling properties. There is no obvious inflammatory reaction, so it can be seen that the anti-adhesion material obtained by the present invention has good biocompatibility. The cast films of Comparative Exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com