Clean production method for processing saporin from yellow ginger

A production method and clean technology, applied in the field of turmeric processing saponin, can solve the problems of serious pollution, low degree of resource utilization, long production cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

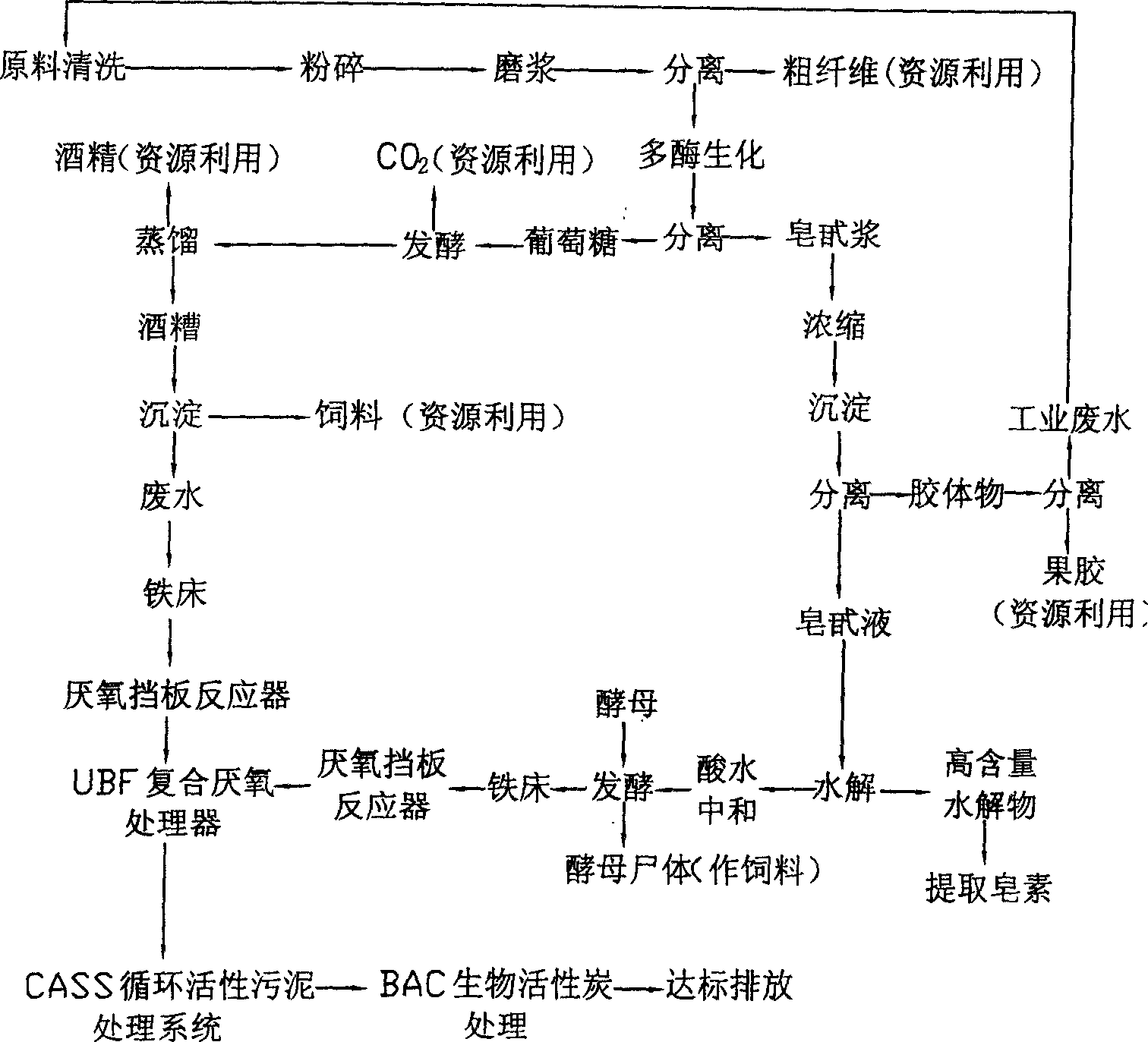

[0012] refer to picture , the cleaning method of turmeric processed saponin of the present invention is exemplified as follows.

[0013] After cleaning, pulverizing and refining the turmeric raw materials, pass through 18-mesh sieve and 40-mesh sieve successively to remove the crude fiber accounting for 1 / 3 of the raw material amount to obtain raw pulp. Then use a vacuum filter to carry out vacuum suction filtration to the raw material slurry, and suction filtration separates clear water. Heat the remaining starch and saponin slurry to 100°C (generally not lower than 95°C) to gelatinize and add amylase with a mass ratio of 0.0001. After visual inspection, if the starch paste is very viscous, the mass ratio of amylase can be increased to the highest. to 0.0005; then lower the temperature to 70°C and add glucoamylase with a mass ratio of 0.0005. After visual inspection in the previous step, if the starch paste is very viscous, the mass ratio of glucoamylase can be increased to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com