Process for preparing nano mesoporous titanium dioxide at low tempeature

A titanium dioxide, nano-mesoporous technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of small specific surface area and large grain size, and achieve the effect of high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

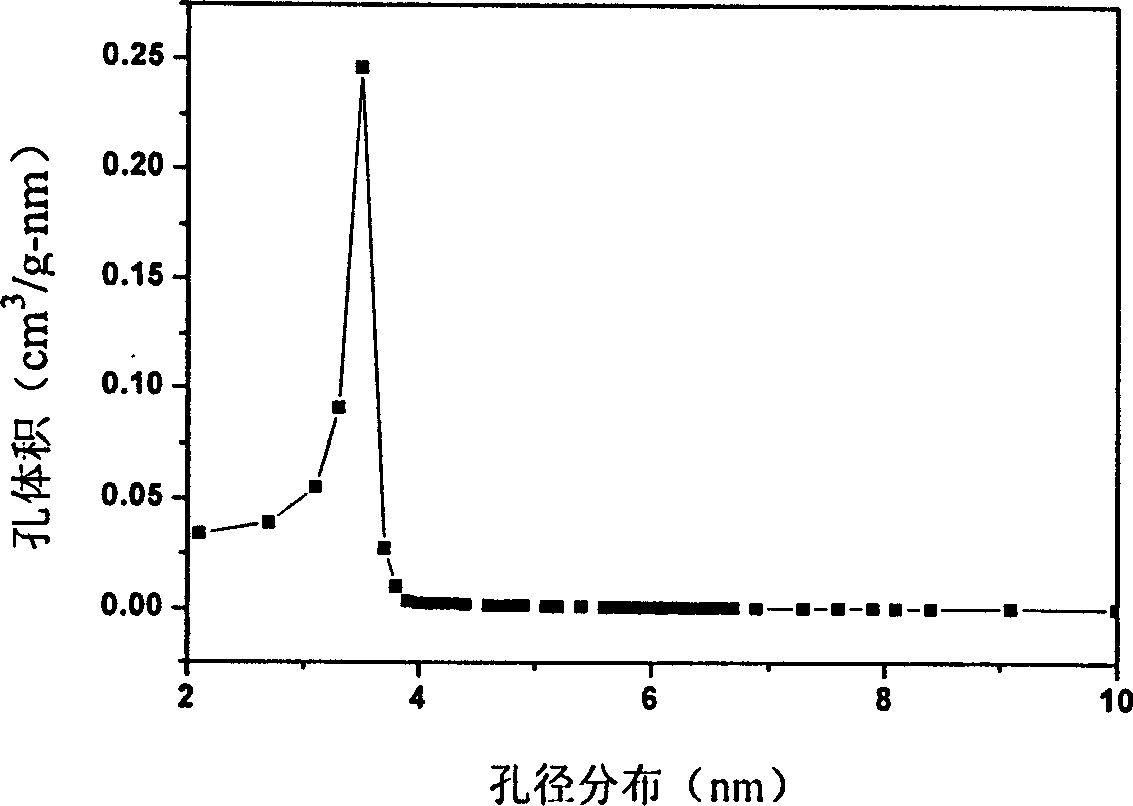

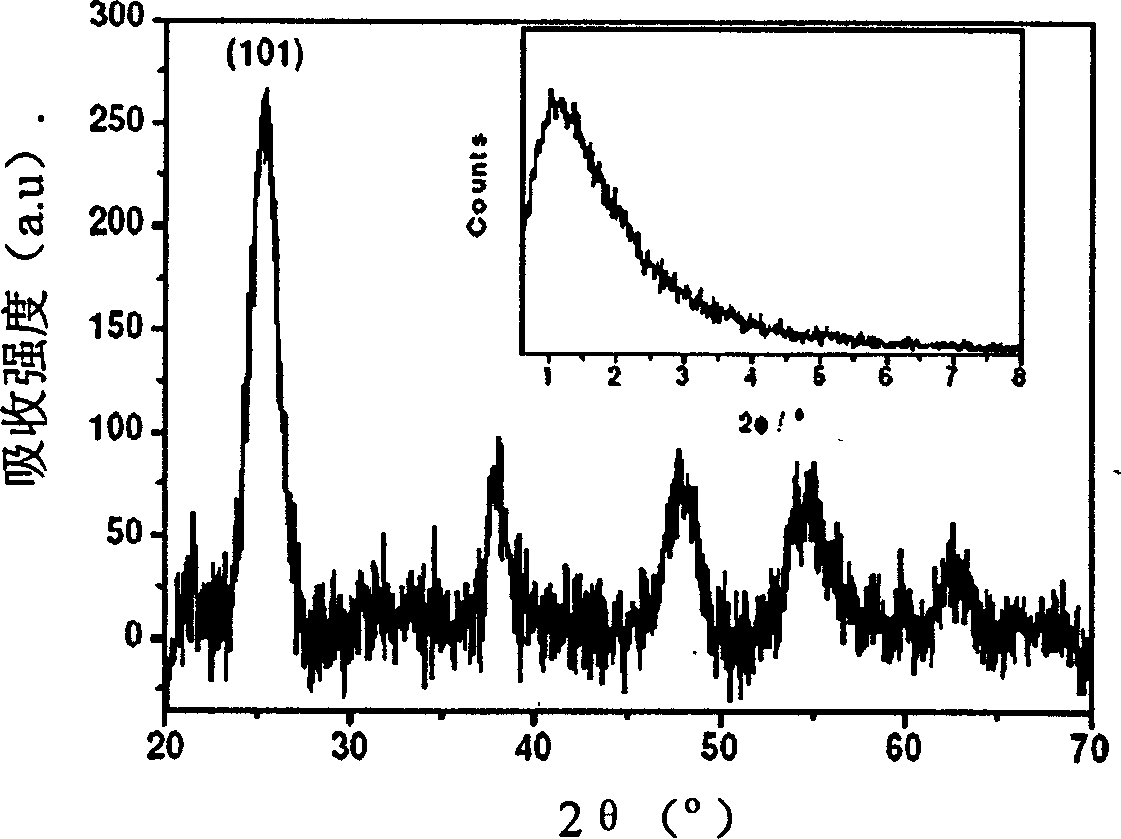

[0020] Example 1: Dissolve 10ml of butyl titanate in 20ml of absolute ethanol solution, stir and mix. In addition, dissolve 3g of P123 in 45ml of absolute ethanol, then add 2.6ml of 2mol / L dilute hydrochloric acid, and stir to mix. Add this solution dropwise to the ethanol solution of butyl titanate, stir at 40°C for 1 hour, let it stand and solidify for 20 hours, then let it dry at room temperature to form a xerogel and grind it into powder. Take 3.5g of finely ground dry powder, put it into 111.4ml of 0.15mol / L hydrochloric acid ethanol solution (1.4ml of concentrated hydrochloric acid + 10ml of water + 100ml of absolute ethanol), heat to 78°C and stir and reflux for 24h. Centrifuge at high speed, wash the precipitate three times with water, and then wash once with absolute ethanol. Dry at 80°C for 12 hours to obtain a specific surface area of 234.5m 2 / g, mesopore size is 3.4nm (by figure 1 It can be seen from the pore size distribution diagram), the grain size is abou...

Embodiment 2

[0021] Example 2: 10ml of butyl titanate was dissolved in 20ml of absolute ethanol solution, and stirred and mixed. In addition, dissolve 3gP123 in 45ml of absolute ethanol, then add 2.6ml of 2mol / L dilute hydrochloric acid, stir and mix. Add this solution dropwise to the ethanol solution of butyl titanate, stir at 40°C for 1 hour, let it stand and solidify for 20 hours, then let it dry at room temperature to form a xerogel and grind it into powder. Take 2.5g of finely ground dry powder, put it into 80ml of 0.4mol / L hydrochloric acid ethanol solution (2.6ml of concentrated hydrochloric acid + 7.4ml of water + 70ml of absolute ethanol), heat to 78°C and stir and reflux for 24h. Centrifuge at high speed, wash the precipitate three times with water, and then wash once with absolute ethanol. Dry at 80°C for 12 hours to obtain a specific surface area of 202.7m 2 Titanium dioxide mixed crystal powder containing 80% anatase phase and 20% crystal redite phase with a mesopore size ...

Embodiment 3

[0022] Example 3: 10 ml of butyl titanate was dissolved in 20 ml of absolute ethanol solution, and stirred and mixed. In addition, dissolve 3g of P123 in 45ml of absolute ethanol, then add 2.6ml of 2mol / L dilute hydrochloric acid, and stir to mix. Add this solution dropwise to the ethanol solution of butyl titanate, stir at 40°C for 1 hour, let it stand and solidify for 20 hours, then let it dry at room temperature to form a xerogel and grind it into powder. Take 6.0 g of finely ground dry powder, put it into 155 ml of 2.35 mol / L hydrochloric acid ethanol solution (30 ml of concentrated hydrochloric acid + 5 ml of water + 120 ml of absolute ethanol), and heat to 78°C and stir and reflux for 24 hours. Centrifuge at high speed, wash the precipitate three times with water, and then wash once with absolute ethanol. Dry at 80°C for 12 hours to obtain a specific surface area of 165.9m 2 / g, titanium dioxide powder in the rutile phase with a mesopore size of 4.0nm and a grain siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com