Inductance coupled coil and inductance coupled plasma device

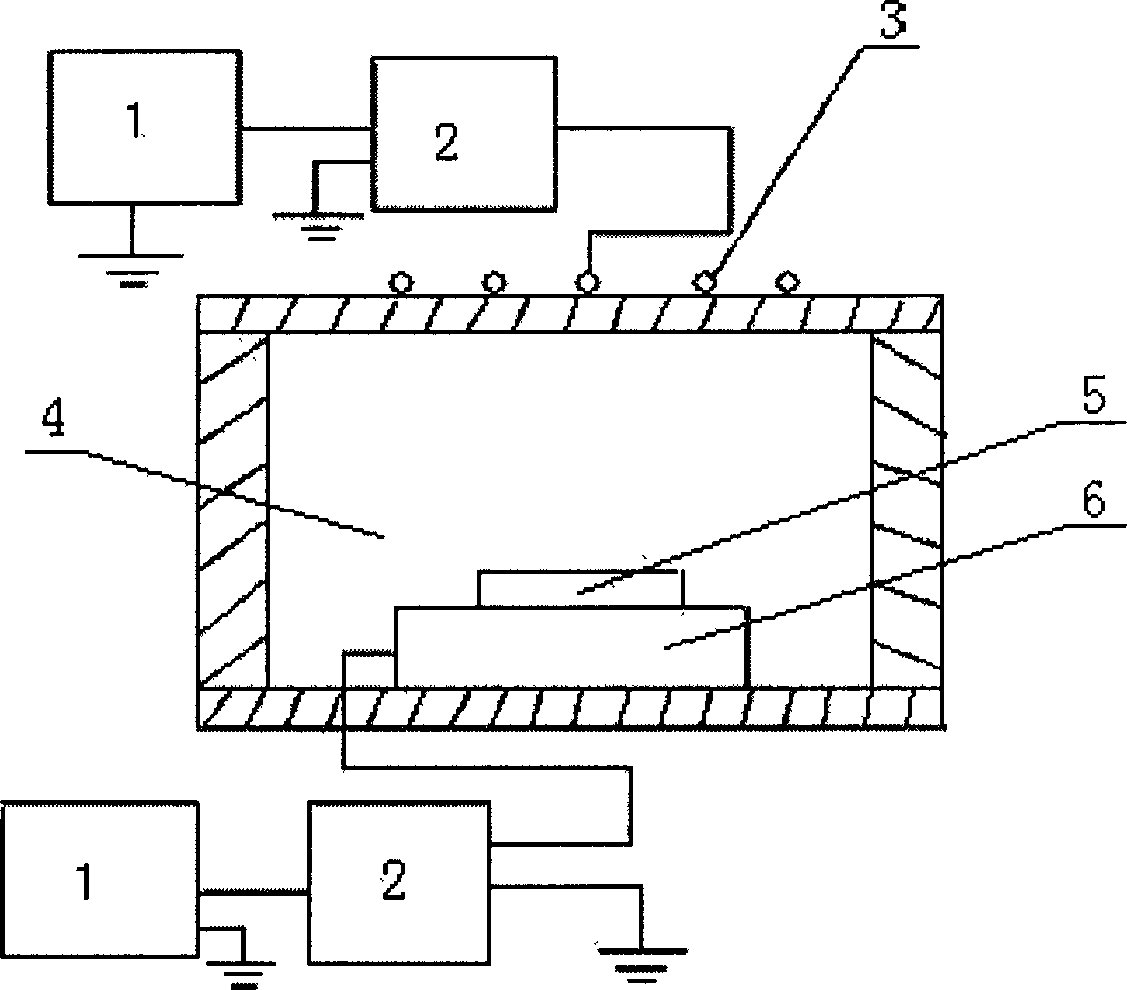

A technology of inductively coupled coils and coils, applied in the direction of plasma, coils, circuits, etc., can solve the problems of increased volume, uneven etching rate, difficult plasma density, etc., to improve quality, improve distribution uniformity, improve The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

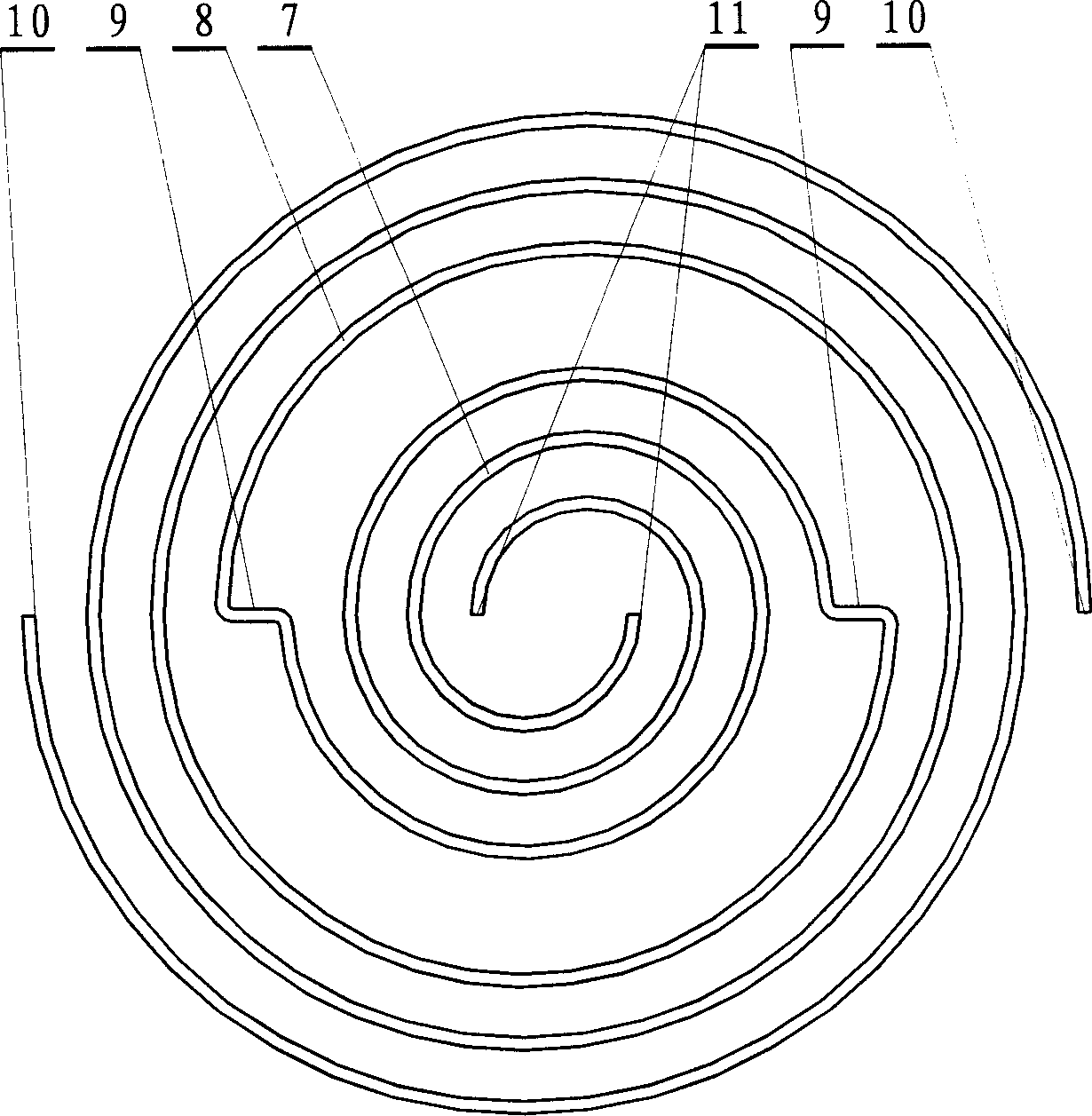

[0027] For a wafer 5 of 300mm, use such as image 3 In the shown inductive coupling coil, a set of involute coils of the inductive coupling coil is composed of an inner coil 7 and an outer coil 8, the inner coil 7 is a one-and-a-half-turn involute-shaped coil, and the outer coil 8 is a one-and-a-half turn involute coil Wire-shaped coils; the inner coil 7 and the outer coil 8 are connected in series through a connecting coil 9 to form a group of involute coils. Two sets of involute coils are nested to form an inductively coupled coil. The two ends of the inner ring of the two sets of involute coils are the output ends 11 , and the two ends of the outer ring are the input ends 10 . Of course, according to different requirements in practical applications, the inner coil 7 and the outer coil 8 may also adopt involute coils with less than one and a half turns or more.

Embodiment 2

[0029] Such as Figure 4 As shown, a group of involute coils of an inductively coupled coil is composed of an inner coil 7 and an outer coil 8, the inner coil 7 is a two-turn involute-shaped coil, and the outer coil 8 is a two-turn involute-shaped coil; The coil 7 and the outer coil 8 are connected in series through a connecting coil 9 to form a group of involute coils. Two sets of involute coils are nested to form an inductively coupled coil. The two ends of the inner circle of the two groups of involute coils are input ends 10 , and the two ends of the outer circle are output ends 11 .

Embodiment 3

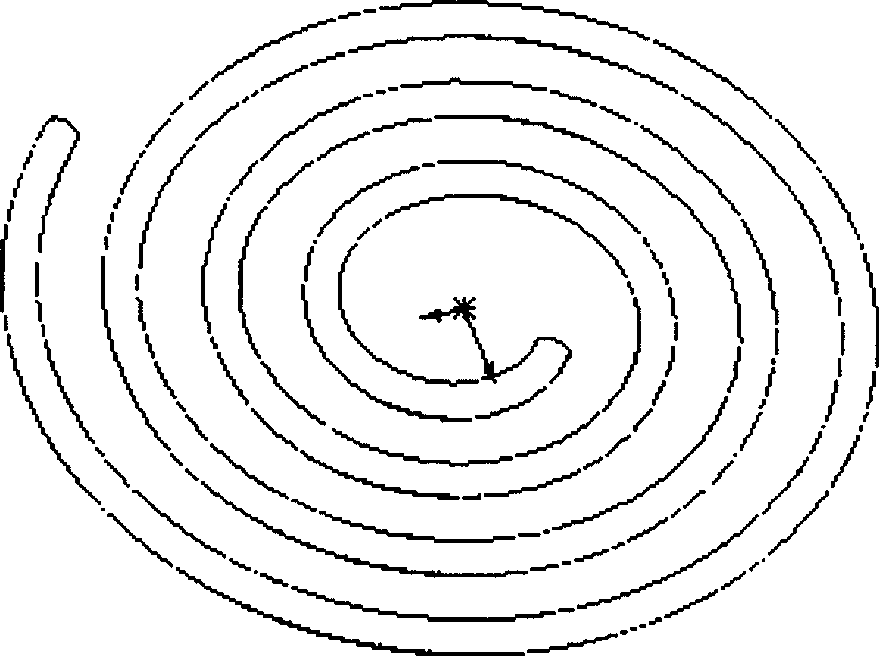

[0031] For a 200mm wafer 5, such as Figure 5 In the shown inductive coupling coil, a group of involute coils of the inductive coupling coil is a two-and-a-half-turn involute-shaped coil, and two sets of involute coils are nested to form the inductive coupling coil. The two ends of the inner ring of the two sets of involute coils are the output ends 11 , and the two ends of the outer ring are the input ends 10 . Certainly, according to different requirements in practical applications, the involute coil may be an involute-shaped coil with less than two and a half turns or more.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com