Method of forming a nanogap and method of manufacturing a nano field effect transitor for molecular device and bio-sensor, and molecular device and bio-sensor manufactured using the same

A field-effect transistor and biosensor technology, which is applied in the fields of forming nano-gap, nano-field-effect transistors for molecular devices and biosensors, and molecular devices and biosensors made by the nano-gap, can solve complex procedures, heavy workloads, etc. Problems such as low visibility, light source dispersion phenomenon, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, a method of forming a nanogap for a molecular device or a biosensor and a method of manufacturing a nanofield effect transistor for a molecular device or a biosensor will be described in detail according to preferred embodiments of the present invention with reference to the accompanying drawings.

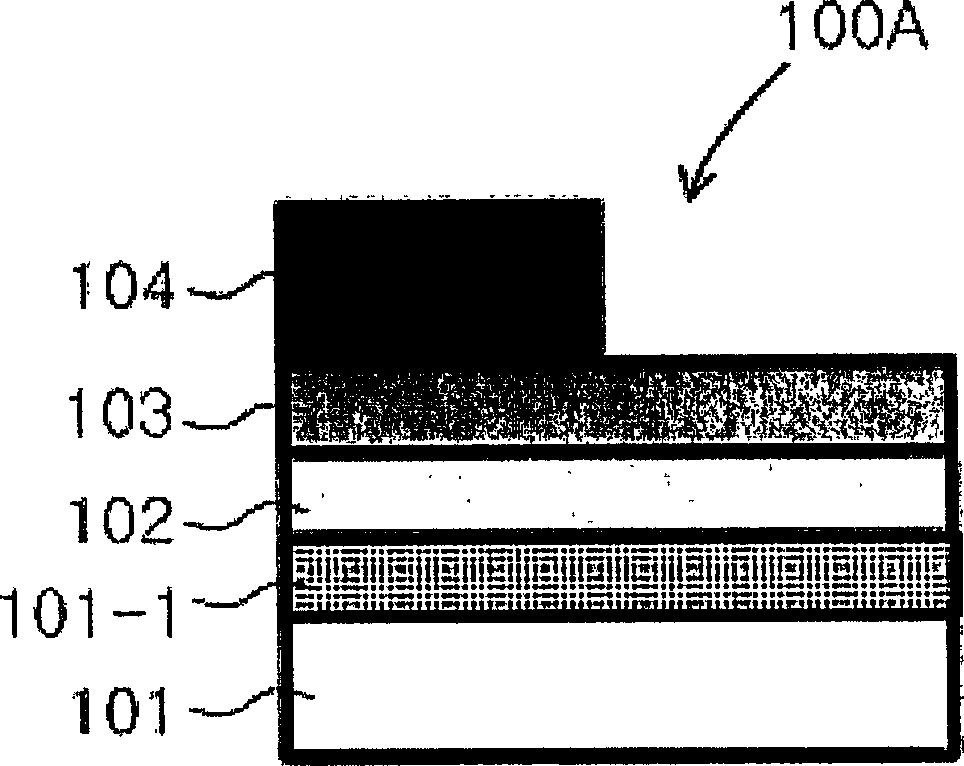

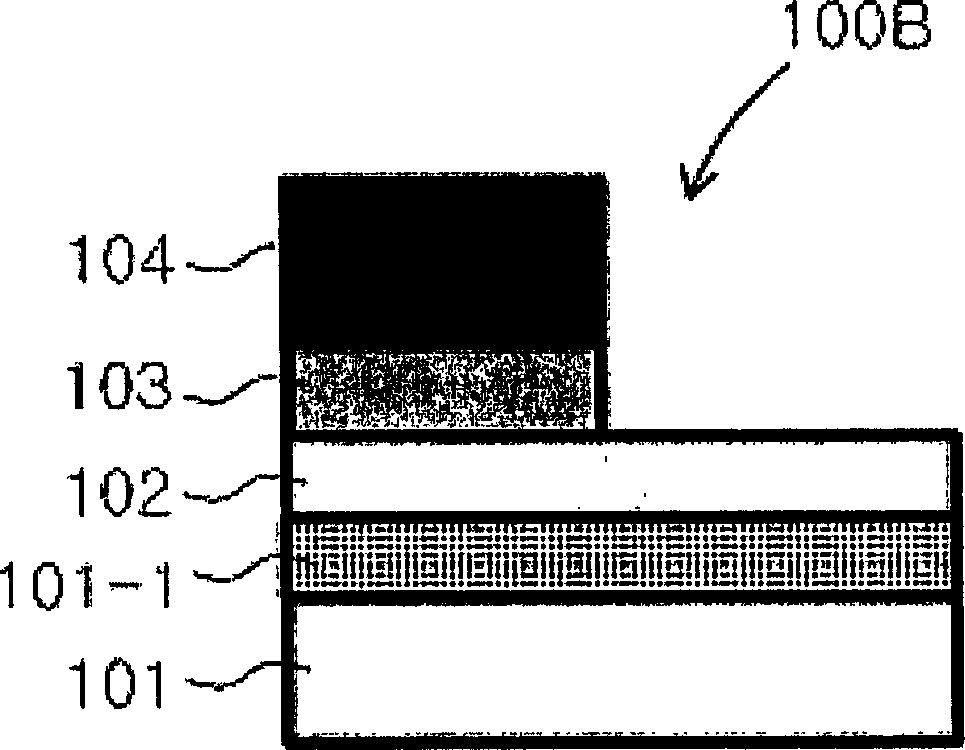

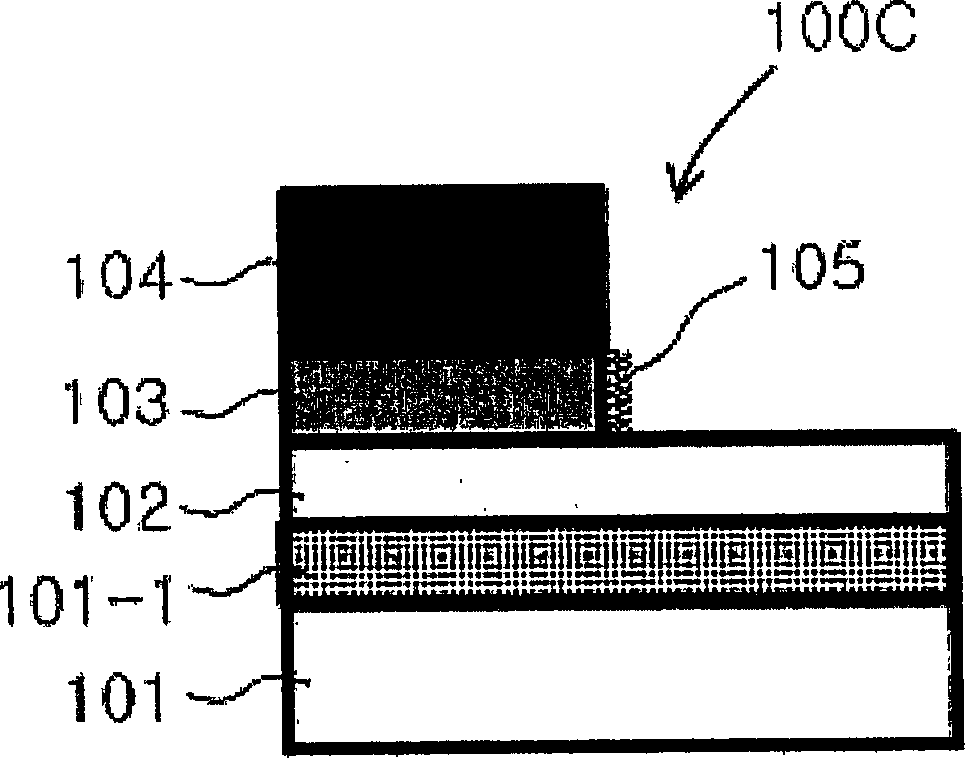

[0037] Figure 1a-1f is a series of cross-sectional views showing sequentially a method of forming a planar nanogap for a biosensor according to an embodiment of the present invention.

[0038] As shown in the figure, a first gold (Au) layer (metal layer) is formed on a silicon substrate, and a second gold layer isolated from the first gold layer is formed using a self-assembled monolayer (hereinafter referred to as "SAM") , thus forming a planar nanogap corresponding to the length of the SAM.

[0039] The method of forming the nanogap is described in detail as follows.

[0040] First, a back gate thin layer 101-1, an insulating layer 102, a first gold layer 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com