Anisotropic scattering sheet

An anisotropic, diffuser technology, applied in the field of transmissive liquid crystal display devices and their flat or flat light source equipment, can solve problems such as unsuitable for long-term stable use, uneven brightness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

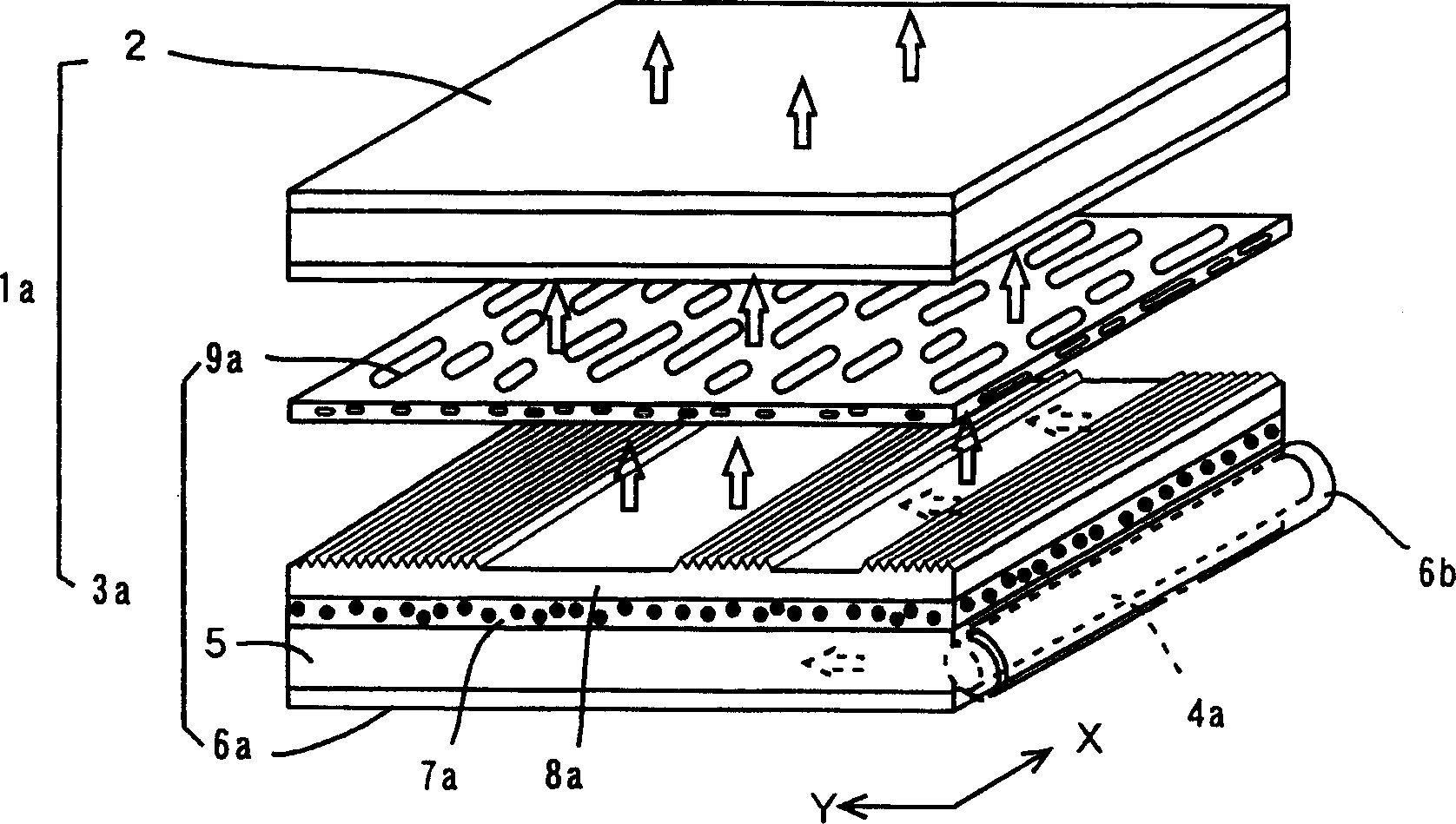

Embodiment 1

[0220] Use 91 parts by weight of crystalline polypropylene resin PP (manufactured by Grand Polymer Co.; F1033, refractive index 1.503) as the continuous phase resin; use 7 parts by weight of polystyrene resin (GPPS) (general polystyrene) Resin, manufactured by Daicel Chemical Industries, Ltd.; GPPS#30, refractive index 1.589) as the dispersed phase resin; 1 part by weight of epoxidized diene block copolymer resin (manufactured by Daicel Chemical Industries, Ltd.; Epofriend AT202; Styrene / butadiene = 70 / 30 (weight ratio), epoxy equivalent 750, refractive index about 1.57) as a compatibilizer. The refractive index difference between the continuous phase resin and the dispersed phase resin is 0.086.

[0221] The continuous phase resin and the dispersed phase resin are dried at 70°C for about 4 hours, and the dried resin is kneaded in a closed mixer. In order to obtain a laminated sheet with a three-layer structure (180μm thick), a multi-layer extruder was used to combine the mixture ...

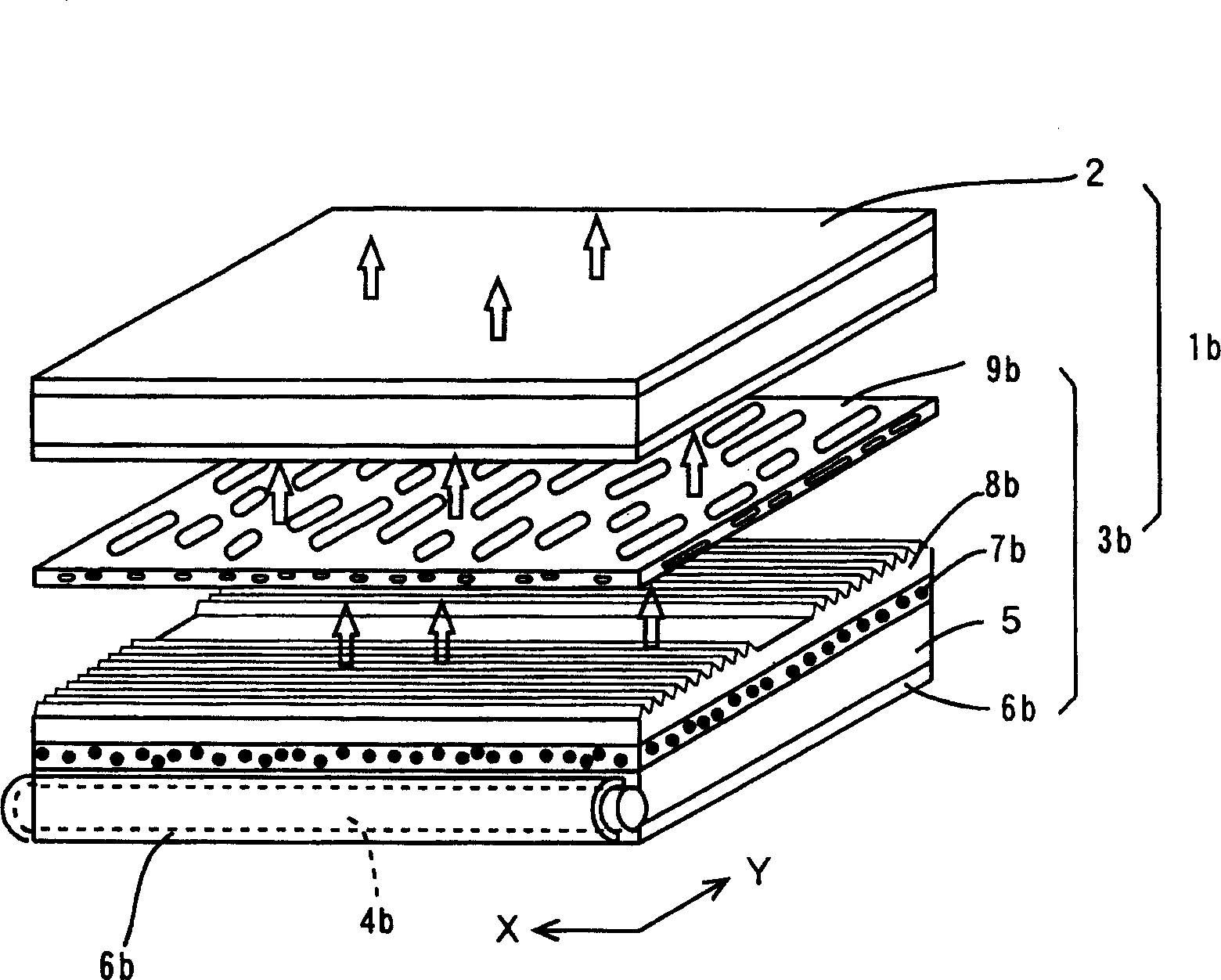

Embodiment 2

[0229] A heat resistance test was performed on an anisotropic scattering sheet made in the same manner as in Example 1, except that the sheet was heat-treated at a temperature of 70°C for 8 hours instead of being heat-treated at a temperature of 90°C for 8 hours.

Embodiment 3

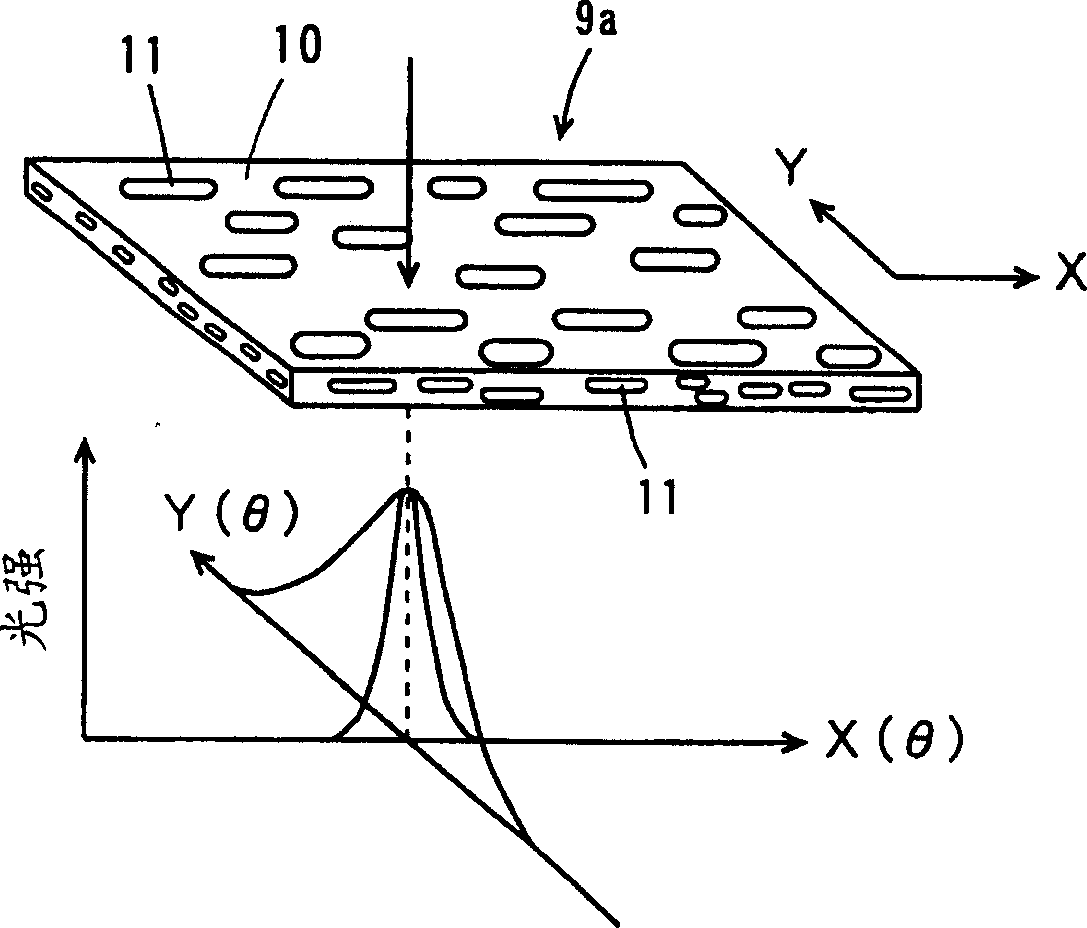

[0231] Further using the roll calendering method (conditions: at a temperature of 125 ℃, the elongation factor is about 2 times (about 1 / 2 of the thickness reduction rate), the width reduction rate is about 3%) uniaxial stretching obtained in Example 1 The anisotropic scattering sheet to obtain a 90μm thick film. Observing the film with TEM (osmic acid coloring), it was found that the shape of the dispersed phase of the intermediate layer resembled a highly stretched fiber, the average length of the long axis was about 30 μm, and the average length of the short axis was about 1.5 μm.

[0232] When the light scattering characteristics of the obtained highly anisotropic uniformly anisotropic scattering sheet were measured by the same method as in Example 1, it was observed that Figure 5 Significant light scattering characteristics shown. In addition, in the light scattering characteristics, Fy(4°) / Fx(4°) is approximately 8.2, Fy(10°) / Fx(10°) is approximately 400, and Fy(30°) / Fx(30°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com